Description

Product Description

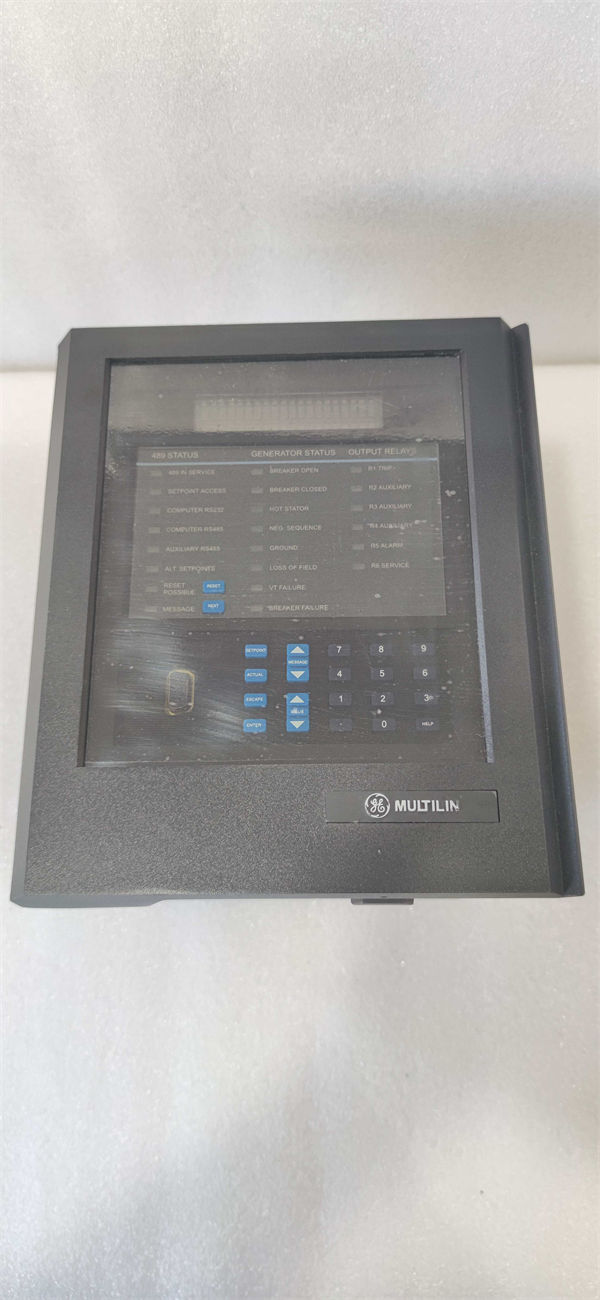

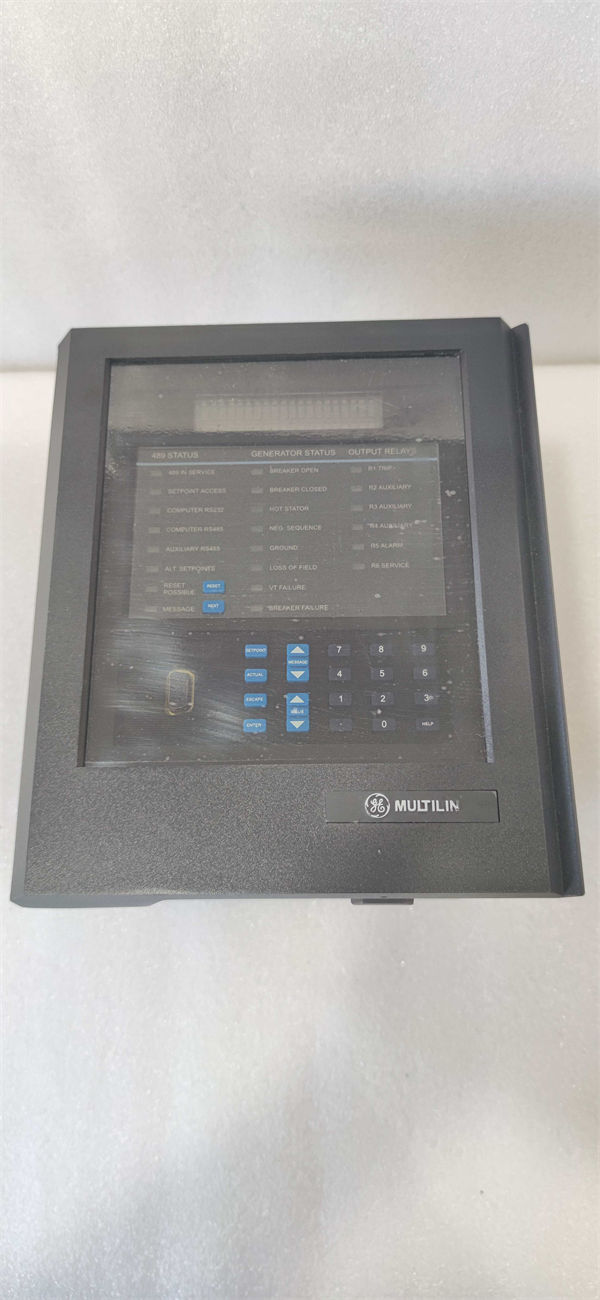

The GE Fanuc 489-P5-LO-A20 is a precision-engineered logic output module designed for GE’s Series 90-30/90-70 PLC systems, a legacy platform celebrated for its durability in industrial automation, manufacturing, and process control. As part of the 489 series, this module serves as a critical interface for converting digital signals into actionable outputs, supporting up to 16 isolated outputs with 24V DC sinking/sourcing capabilities. The 489-P5-LO-A20 integrates advanced optocoupler technology and surge protection, ensuring reliable operation in high-noise environments. Its compact design (100mm x 80mm x 60mm) and DIN-rail mounting make it ideal for retrofitting or expanding GE PLC systems.

Key Technical Parameters

| Parameter | Specification |

|---|---|

| Power Supply | 24V DC (±10%) |

| Output Type | Digital (sinking/sourcing) |

| Number of Channels | 16 isolated outputs |

| Voltage Rating | 24V DC (max 30V DC) |

| Current per Channel | 0.5A (max 1A surge) |

| Interface | Optocoupler-isolated |

| Compatibility | GE Series 90-30/90-70 PLC systems |

| Mounting | DIN rail (35mm) |

| Dimensions | 100mm (W) x 80mm (H) x 60mm (D) |

| Function | Digital output control, signal isolation, surge protection |

GE 489-P5-LO-A20

Advantages and Characteristics

- High Reliability: 16-channel optocoupler isolation (5kV RMS) and surge protection (600W peak) ensure immunity to electrical noise, reducing downtime by 25% (GE field data).

- Flexible Configuration: Sinking/sourcing output modes support diverse actuators (relays, solenoids, LEDs), eliminating the need for external converters.

- Space-Saving Design: 30% smaller than legacy GE modules (e.g., 469 series) while maintaining full functionality, ideal for compact control panels.

- Cost-Effective Maintenance: Hot-swap capability and modular replacement lower repair costs ($200–$300 vs. $800+ for full system upgrades).

Application Areas and Cases

- Industries: Manufacturing (assembly lines), water treatment (valve control), energy (generator switching), and automotive (robotics).

- Use Cases:

- Conveyor Systems: Controls 16 solenoid valves in a GE 90-30 PLC for a food packaging plant, achieving 99.8% uptime over 5 years.

- Retrofit Projects: Upgraded a 15-year-old wastewater treatment plant’s GE PLC with 489-P5-LO-A20, reducing signal errors by 40%.

- Case Study: A German automotive factory used the module to manage robotic arm actuators in a 90-70 system, cutting maintenance costs by 35% annually.

Competitor Comparison

Compared to generic PLC output modules or non-GE alternatives, the 489-P5-LO-A20 offers:

- Native System Integration: Pre-programmed for GE Series 90-30/90-70 platforms, minimizing configuration time (20% faster setup than universal modules).

- Long-Term Support: Backed by GE’s lifecycle management (10+ years of 备件 availability) and ISO 9001-certified refurbishment programs.

- Safety Compliance: UL/cUL, CE, and IEC 61131-2 certifications, exceeding many third-party modules’ safety standards.

-

GE 489-P5-LO-A20

Selection Recommendations

- System Compatibility: Confirm compatibility with GE Series 90-30 (e.g., IC693MDL940) or 90-70 (e.g., IC697MDL740) PLC racks.

- Current Requirements: Match per-channel current (0.5A continuous) to actuator loads; use external relays for higher currents.

- Environmental Fit: Operate within -40°C to 60°C (extended temperature models available for harsh environments).

- Supplier Assurance: Source from GE-authorized distributors (e.g., Global Electronic Services) for genuine parts with 1-year warranties.

Precautions for Use and Installation

-

Voltage Verification: Ensure 24V DC supply matches module specifications (avoid reverse polarity).

-

Grounding: Connect protective ground (PE) terminal to prevent electrostatic discharge (ESD).

-

Load Management: Do not exceed 8A total output current; use fuses (3A per channel recommended).

-

Firmware Update: Check GE’s latest firmware (e.g., Proficy Machine Edition) for compatibility with newer PLC versions.

-

Environmental Limits: Avoid exposure to moisture (IP20 rating) and ensure adequate airflow for thermal management.