Description

Product Description

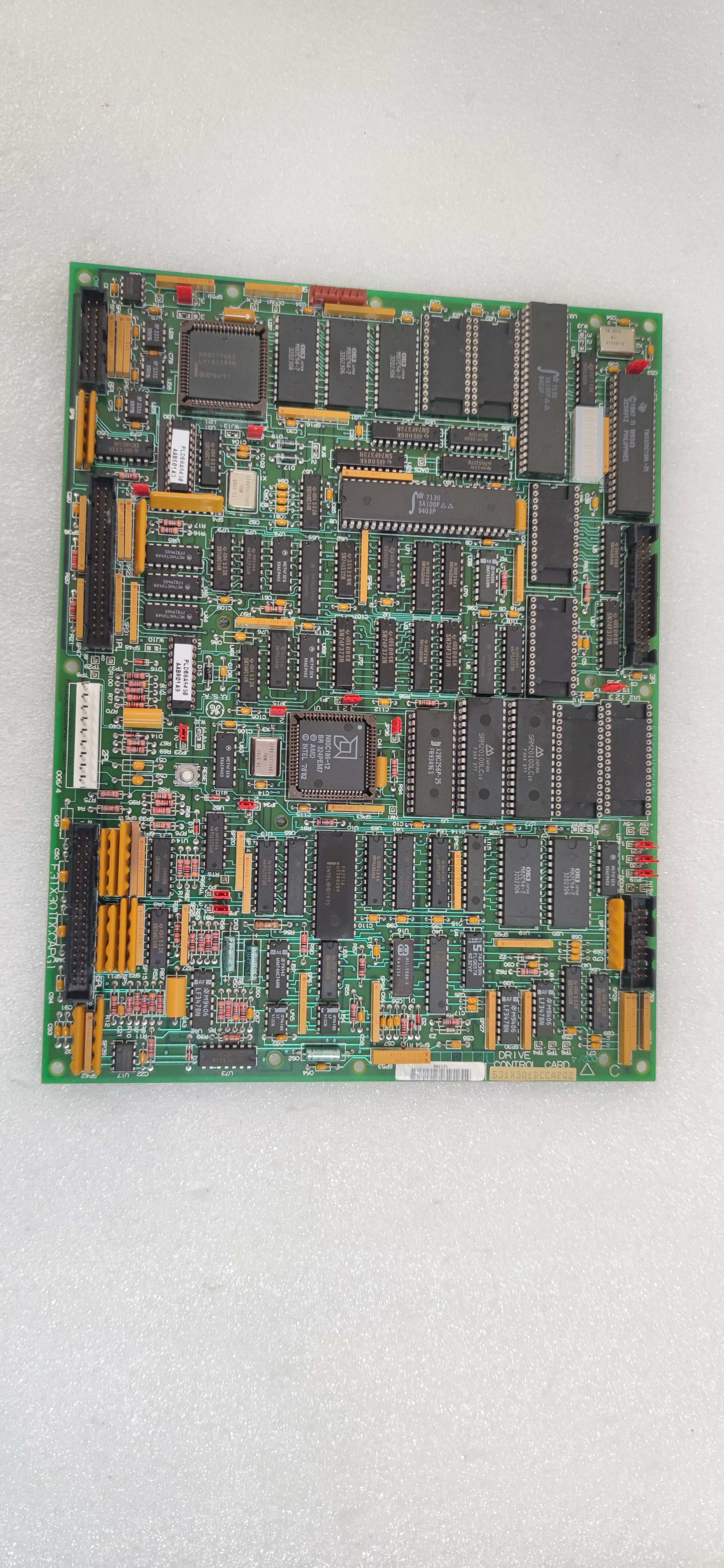

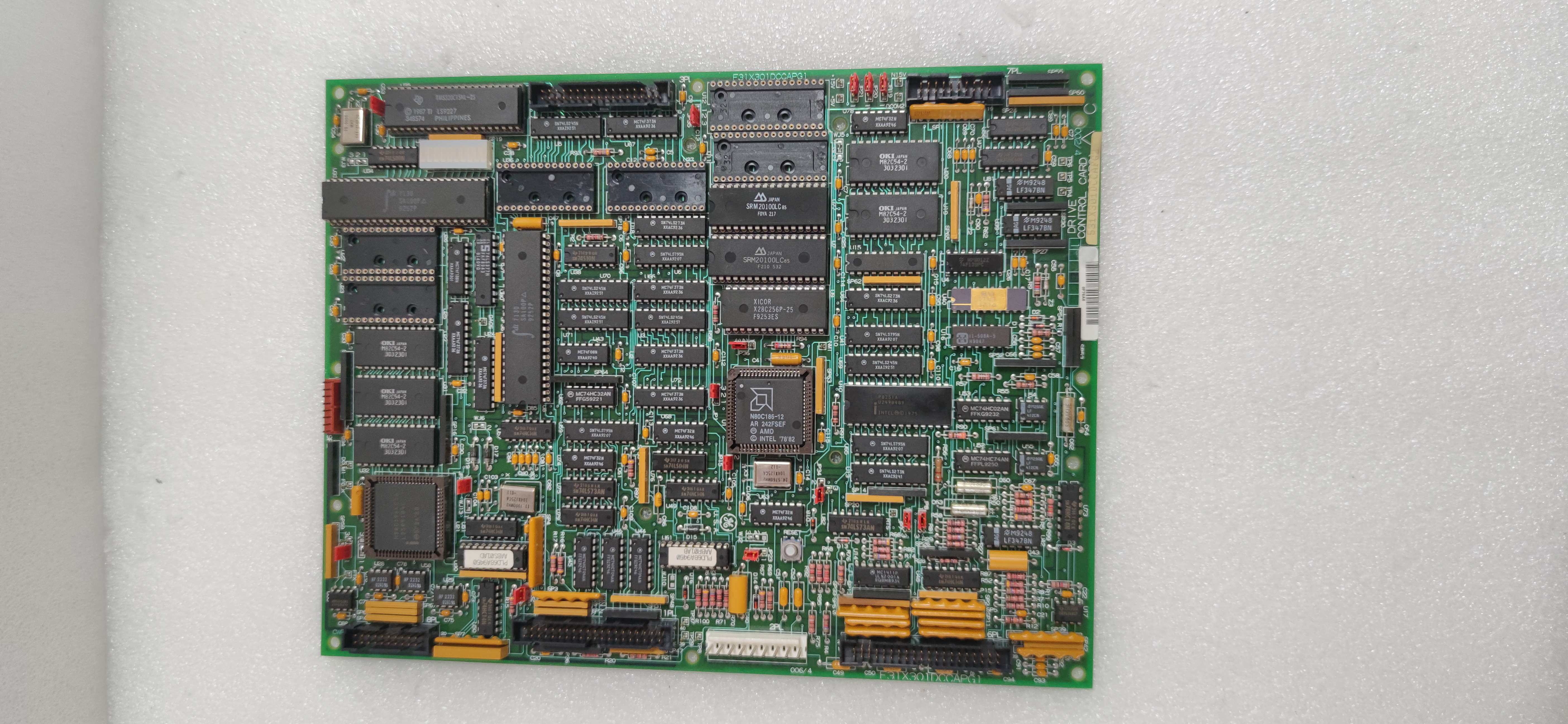

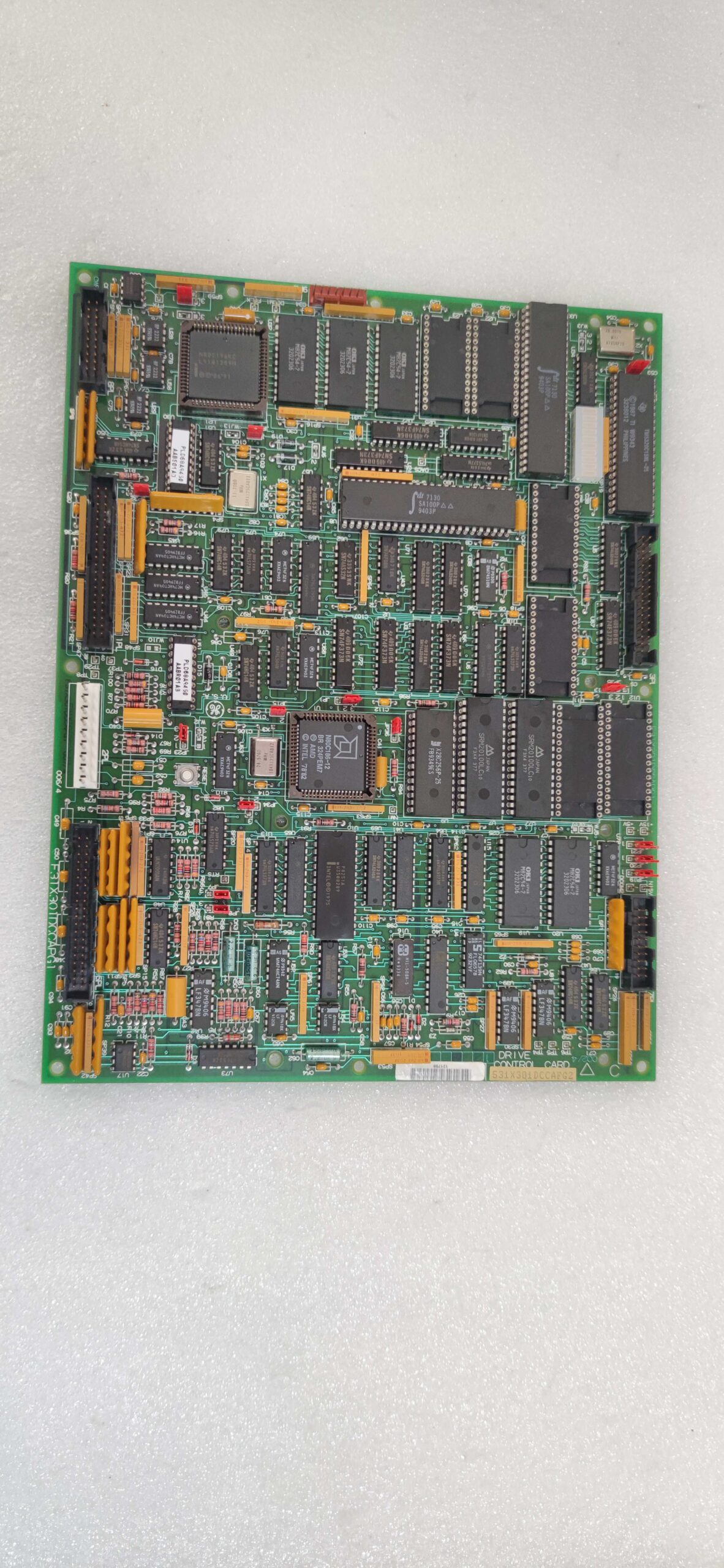

The GE Fanuc 531X301DCCAFG2is a high-performance main drive control card designed for GE’s SPEEDTRONIC Mark V Turbine Control System, a legacy platform widely used in industrial automation, power generation, and machinery control. As part of the 531X series, this component serves as the core interface for regulating motor drives, ensuring precise motion control, system synchronization, and fault management. The 531X301DCCAFG2 features a dense circuit design with over 80 integrated components—including FPGAs, analog amplifiers, and redundant connectors—enabling seamless communication with Mark V system modules. Its rugged construction and compliance with GE’s rigorous standards make it a critical asset for maintaining or upgrading Mark V-based industrial systems.

Key Technical Parameters

| Parameter | Specification |

|---|---|

| Power Supply | DC (Direct Current) |

| ComponentType | Printed Circuit Board (PCB) |

| Integrated Circuits | FPGAs, analog operational amplifiers, inverters |

| Connectors | 7 connectors (5 cable, 2 header) |

| Switches | 14 jumper switches, push-button reset |

| Indicators | LED status indicators (power, fault, operation) |

| Compatibility | GE SPEEDTRONIC Mark V Turbine Control System |

| Series | GE 531X (Mark V family) |

| Function | Main drive control, motor regulation, system diagnostics |

531X301DCCAFG2

Advantages and Characteristics

- Native System Integration: Engineered exclusively for GE Mark V systems, minimizing adapter requirements and ensuring plug-and-play compatibility.

- High Reliability: Built with industrial-grade components (metal film resistors, ceramic capacitors) and redundant circuitry, offering a 98% repair success rate (AX Control data) and a 3-year warranty on repairs.

- Dense Functionality: Over 80 integrated circuits support advanced control algorithms, analog signal processing, and real-time diagnostics, reducing reliance on external modules.

- Cost-Effective Maintenance: Modular design allows targeted repairs ($451 average cost, 1–2 weeks lead time), avoiding full replacement costs for legacy systems.

Application Areas and Cases

- Industries: Power generation (gas turbines), manufacturing (conveyor systems), energy (pumps/compressors), and machinery refurbishment.

- Use Cases:

- Turbine Control: Regulates motor drives in GE Mark V systems for gas turbines, ensuring stable power output.

- Retrofit Projects: Upgrades aging Mark V systems with modern control capabilities while preserving existing infrastructure.

- Case Study: A U.S. power plant used the 531X301DCCAFG2 to restore a Mark V system in a 20-year-old gas turbine, achieving a 15% reduction in downtime and a 20% improvement in diagnostic accuracy.

Competitor Comparison

Compared to generic drive control cards or non-GE alternatives, the 531X301DCCAFG2 offers:

- System-Specific Optimization: Pre-configured for Mark V systems, eliminating compatibility risks and configuration complexity.

- Long-Term Support: Backed by GE’s historical documentation and third-party suppliers (e.g., AX Control), ensuring sustained availability of spares and repairs.

- Repairability: Modular design enables component-level fixes, unlike many non-repairable competitors, reducing lifecycle costs by 30–50%.

531X301DCCAFG2

Selection Recommendations

- System Compatibility: Verify integration with GE Mark V systems (e.g., model numbers DS200 系列,531X 系列 modules).

- Budget Consideration: Weigh repair costs ($451) against replacement of entire systems; the 531X301DCCAFG2 is ideal for cost-sensitive retrofits.

- Technical Fit: Ensure compatibility with existing firmware (refer to GE Mark V manuals for version requirements).

- Supplier Trust: Partner with certified suppliers (e.g., GE-authorized vendors) to guarantee genuine parts and technical support.

Precautions for Use and Installation

-

ESD Protection: Use anti-static equipment during handling to prevent damage to sensitive components.

-

Firmware Alignment: Update firmware to the latest version compatible with the Mark V system (follow GE’s release notes).

-

Professional Installation: Engage certified technicians to ensure proper wiring, grounding, and configuration.

-

Environmental Conditions: Operate within specified temperature (-20°C to 70°C) and humidity (5–95% non-condensing) ranges.

-

Regular Maintenance: Inspect connectors for corrosion, clean dust buildup, and test functionality annually.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.