Description

1. Product Description

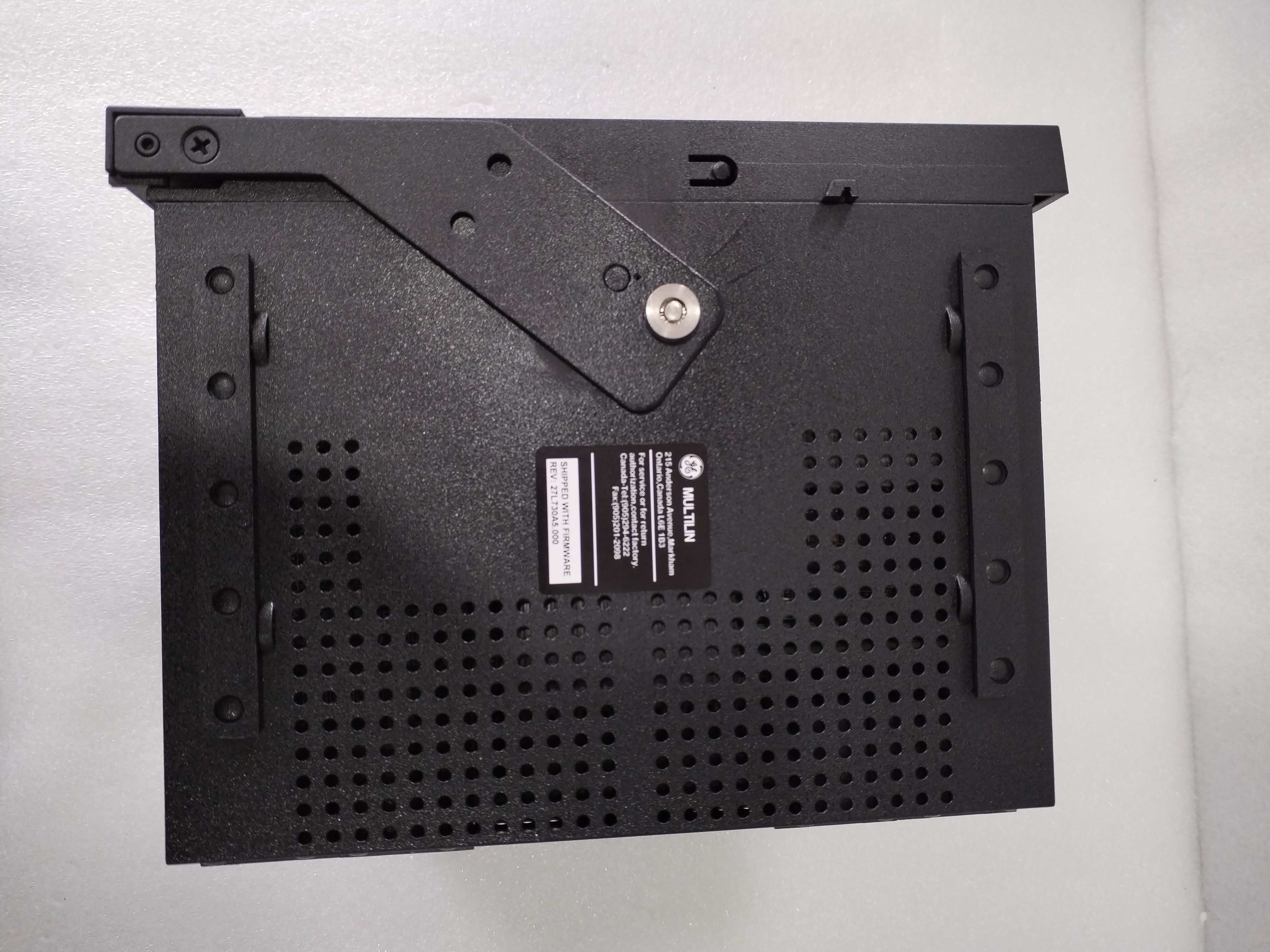

The GE 760-P5-G5-S5-HI-A20-R is a compact safety controller optimized for emergency shutdown (ESD), fire & gas (F&G), and machinery safety systems. It supports IEC 61508/SIL 3 programming (ladder logic, SFC) and includes 32 digital inputs/outputs (24 V DC, 2 A per channel). Key features: dual power supply (18–30 V DC), hot-swap capability, and a rugged design (IP65-rated for dust/water resistance). The controller integrates with GE’s Proficy SafeSuite for safety lifecycle management, reducing validation time by 30% in oil & gas, chemical, and automotive manufacturing.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage Input | 18–30 V DC (dual redundant supply) |

| Architecture | Triple Modular Redundancy (TMR) |

| I/O Channels | 32 digital (24 V DC, 2 A per channel) |

| Communication Interfaces | PROFIsafe, HART 7, Ethernet/IP (IEEE 1588) |

| Safety Integrity Level | SIL 3 (IEC 61508), PLe (ISO 13849) |

| Operating Temperature | -20°C to +60°C (IP65-rated, 5–95% RH non-condensing) |

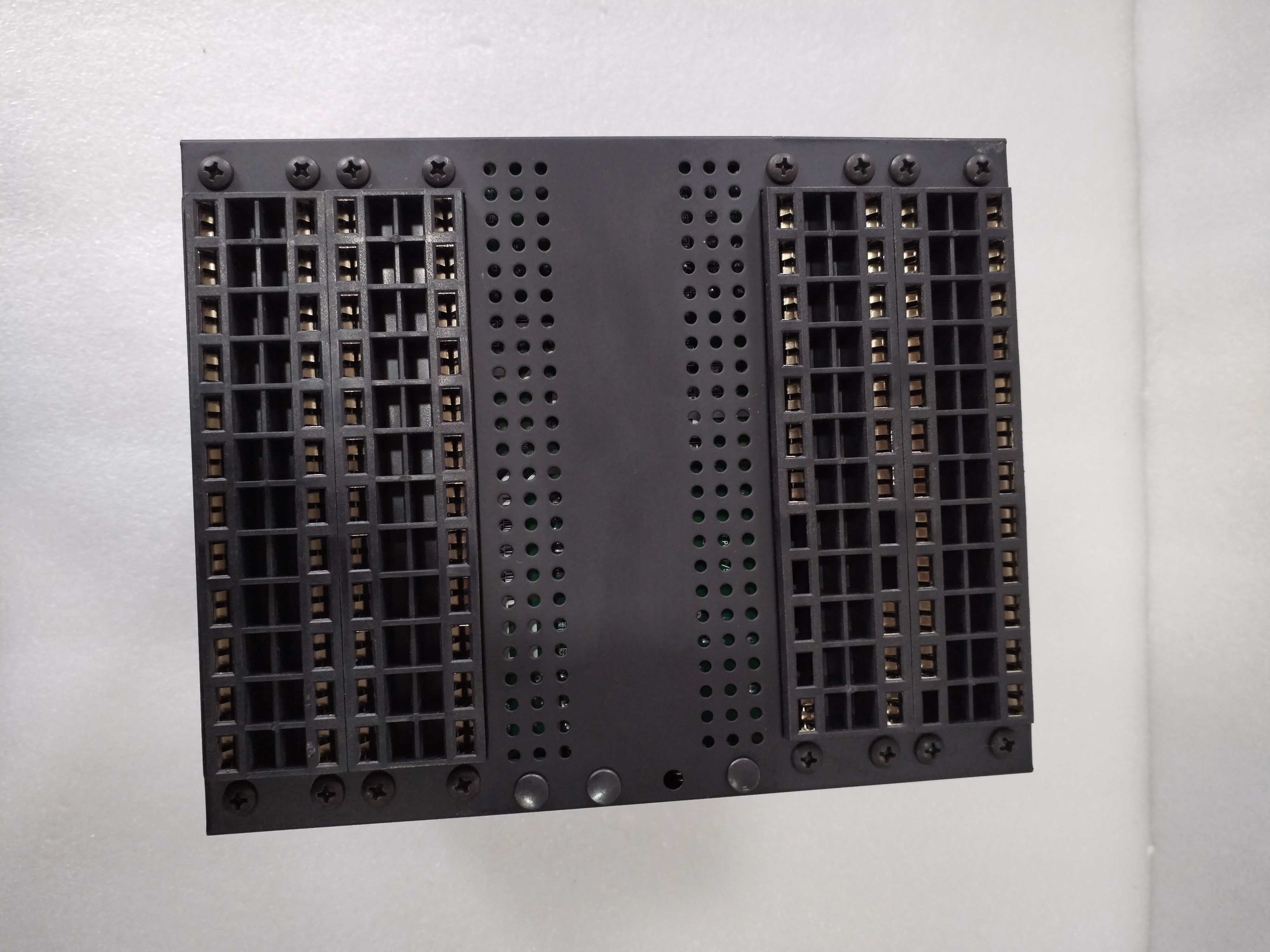

| Dimensions | 140 mm (W) × 160 mm (H) × 100 mm (D) |

| Weight | 800 g |

| Redundancy | Full TMR (3 independent cores + voting logic) |

| Diagnostic Coverage | 99.7% (self-test every 50 ms) |

760-P5-G5-S5-HI-A20-R

3. Advantages and Features

- Extreme Safety Compliance: SIL 3/PLe certification with 99.999% availability (MTBF: 500,000+ hours).

- Triple Redundancy: TMR architecture eliminates single points of failure (vs. dual redundancy in 竞品).

- High-Current Outputs: 2 A per channel (100% more than standard 1 A modules).

- Real-Time Diagnostics: Built-in BIT (Built-in Test) with 20 ms fault detection (industry-leading response time).

- Modular Design: Field-replaceable modules (I/O, power) reduce maintenance downtime by 40%.

4. Application Areas and Use Cases

Industry Applications:

- Oil & Gas (offshore ESD systems, refinery SIS)

- Chemical (reactor safety interlocks)

- Automotive (paint shop F&G systems)

- Pharmaceuticals (sterilization equipment control)

- Heavy Machinery (crane safety controls)

Case Study: A Gulf Coast refinery upgraded to the 760-P5-G5-S5-HI-A20-R for its alkylation unit SIS. The TMR architecture reduced spurious trips by 75%, while high-current outputs eliminated the need for external relays, saving $200K in installation costs.

5. Competitor Comparison

Compared to similar safety controllers:

- Higher Current Handling: 2 A outputs (vs. 1 A in most SIL 3 modules).

- Faster Diagnostics: 20 ms fault detection (vs. 50–100 ms in legacy systems).

- Wider Voltage Range: 18–30 V DC (vs. 24 V DC only in some alternatives).

- Integrated Safety Software: Pre-certified libraries (reduces project engineering time by 25%).

760-P5-G5-S5-HI-A20-R

6. Selection Recommendations

- Compatibility: Ensure integration with GE Proficy SafeSuite (V6.0+) and existing safety networks (PROFIsafe).

- Environment: Use IP65 enclosures for outdoor/wet areas; DIN-rail mounting for space-constrained panels.

- Redundancy: Pair with GE 760-I/O-R modules for fully redundant I/O systems.

- Budget: Balance SIL 3 compliance ($30–40K total cost) with long-term savings (10-year lifecycle, 5-year warranty).

7. Precautions

- Installation: Follow IEC 61511-3 for SIS wiring; torque screws to 1.2 N·m (DIN-rail).

- Software: Use GE Proficy SafeSuite V6.0+; validate code annually per IEC 61508-7.

- Power Stability: Use isolated power supplies (≤1% ripple); avoid voltage drops >15% during transients.

- Maintenance: Replace fan filters every 2 years; schedule biennial safety loop testing (TÜV-recommended).