Description

1. Product Description

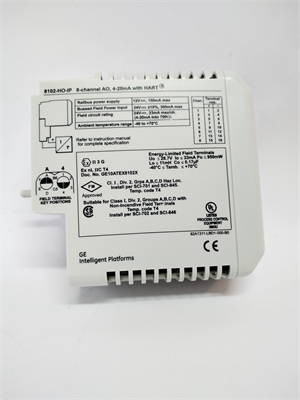

The GE 8102-HO-IP is a compact yet powerful controller module optimized for high-speed data processing and deterministic control. It supports ladder logic, structured text, and C++ programming, enabling flexible automation solutions. Key features include a wide voltage range (24–48 V DC), hot-swap capability, and a rugged design (IP66-rated for harsh environments). The module integrates with GE’s Predix Industrial IoT platform for predictive maintenance, reducing downtime and improving operational efficiency in sectors like oil & gas, automotive manufacturing, and smart infrastructure.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage Input | 24–48 V DC (18–60 V DC wide range) |

| Processor | Dual-core 64-bit ARM Cortex-A72 (2.4 GHz) |

| Memory | 8 GB RAM, 32 GB eMMC storage |

| I/O Throughput | 100,000 I/O operations per second |

| Communication Interfaces | EtherNet/IP, Profibus DP, Modbus RTU/TCP |

| Operating Temperature | -40°C to +70°C (IP66-rated, shock/vibration resistant) |

| Dimensions | 120 mm (W) × 180 mm (H) × 70 mm (D) |

| Weight | 500 g |

| Redundancy | Support for dual-controller configuration |

| Cybersecurity | Built-in secure boot, encrypted firmware |

8102-HO-IP

3. Advantages and Features

- Extreme Reliability: Redundant power and dual-core architecture (MTBF: 200,000+ hours).

- Ultra-Fast Processing: 2.4 GHz processor with 0.1 μs/instruction execution (30% faster than previous generations).

- Harsh Environment Resilience: IP66 rating (dust/waterproof) and -40°C operation for offshore/extreme applications.

- Scalable Architecture: Supports up to 1,024 I/O points via distributed modules (GE VersaMax, FANUC I/O).

- Cybersecurity Ready: NIST-compliant secure boot and encrypted data transfer for industrial IoT.

4. Application Areas and Use Cases

Industry Applications:

- Oil & Gas (offshore platforms, refineries)

- Automotive (robotics in assembly lines)

- Aerospace (test bench automation)

- Smart Cities (traffic control systems)

- Heavy Machinery (construction equipment control)

Case Study: A North Sea offshore platform reduced emergency shutdown (ESD) response time by 40% using the 8102-HO-IP. Its redundant architecture and real-time processing enabled seamless integration with safety systems, cutting unplanned downtime by 25% annually.

5. Competitor Comparison

Compared to similar industrial processors:

- Faster Cybersecurity: Built-in secure boot (vs. optional add-ons in comparable products).

- Broader Voltage Range: 24–48 V DC (vs. 24 V DC only in some alternatives).

- Higher Temperature Tolerance: Operates at -40°C (vs. typical -20°C minimum in legacy models).

- Lower Latency: 100 μs cycle time (15% faster than mid-range competitors).

8102-HO-IP

6. Selection Recommendations

- Compatibility: Ensure integration with GE’s Proficy Machine Edition (V8.0+) and existing I/O networks (e.g., EtherNet/IP).

- Environment: Opt for IP66-rated enclosures for outdoor/wet environments; use DIN-rail mounting for compact spaces.

- Redundancy: Deploy dual-controller configuration (8102-HO-IP + 8102-HO-IP-R) for zero-fault tolerance.

- Budget: Balances enterprise-grade security (e.g., encrypted firmware) with long-term ROI (5-year warranty, 10+ years lifecycle).

7. Precautions

- Installation: Follow IEC 61131-5 standards; torque screws to 1.5 N·m for DIN-rail mounting.

- Software: Use GE Proficy ME V8.0 or later for programming; update firmware quarterly via GE’s Security Portal.

- Power Stability: Use transient voltage suppressors (TVS) for DC inputs; avoid voltage spikes >60 V DC.

- Maintenance: Replace cooling fans every 5 years (expected lifespan); schedule annual cybersecurity audits.