Description

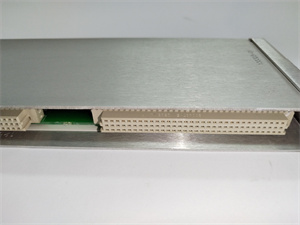

Bently Nevada 133323-01 Modbus RS485 I/O Module

1. Product Description

The Bently Nevada 133323-01 is a high-performance Modbus RS485 I/O module designed for industrial automation and machinery condition monitoring systems. As part of the 3500/92 Communication Gateway, it bridges the gap between rotating equipment (e.g., compressors, turbines) and control systems like PLCs or DCS, enabling real-time data exchange of critical parameters such as vibration, displacement, and speed. With support for Modbus RTU and TCP/IP protocols, the module ensures seamless integration into industrial networks, enhancing operational efficiency and reliability. Its compact design and compatibility with Bently Nevada’s 3500 series make it ideal for retrofitting or expanding existing monitoring setups.

The Bently Nevada 133323-01 is a high-performance Modbus RS485 I/O module designed for industrial automation and machinery condition monitoring systems. As part of the 3500/92 Communication Gateway, it bridges the gap between rotating equipment (e.g., compressors, turbines) and control systems like PLCs or DCS, enabling real-time data exchange of critical parameters such as vibration, displacement, and speed. With support for Modbus RTU and TCP/IP protocols, the module ensures seamless integration into industrial networks, enhancing operational efficiency and reliability. Its compact design and compatibility with Bently Nevada’s 3500 series make it ideal for retrofitting or expanding existing monitoring setups.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Module Type | Modbus RS485 I/O Module |

| Compatibility | 3500/92 Communication Gateway System |

| Input/Output Channels | 32 configurable (digital/analog) |

| Communication Protocols | Modbus RTU (RS485), Modbus TCP/IP |

| Power Supply | 24 VDC (via system rack) |

| Input Signal Range | -10 VDC to +10 VDC |

| Temperature Range | -20°C to +70°C (operating) -40°C to +85°C (storage) |

| Weight | 0.82 kg |

| Dimensions | 24 cm × 2.4 cm × 10 cm |

Bently 133323-01

3. Advantages and Features

- Multi-Protocol Support: Integrates with both serial (RS485) and Ethernet-based systems, ensuring flexibility in communication architectures.

- High Reliability: Built with rugged components to withstand harsh industrial environments, reducing downtime and maintenance costs.

- Scalability: Expands monitoring capabilities by adding up to 32 I/O channels, adapting to evolving industrial needs.

- Configurable Modbus Registers: Offers advanced data mapping options, replacing legacy primary value registers for enhanced customization.

- Energy Efficiency: Low power consumption (5.6 W typical) minimizes operational costs.

4. Application Fields and Case Studies

- Oil & Gas: Monitors compressor vibrations in refineries, transmitting data to DCS for predictive maintenance.

- Power Generation: Integrates with steam turbines to track rotational speed and bearing health, optimizing energy output.

- Manufacturing: Controls conveyor systems in automotive plants, ensuring synchronization and safety.

- Case Study: A leading chemical plant reduced unplanned shutdowns by 30% using the 133323-01 to remotely monitor pump vibrations and trigger alerts via Modbus RTU.

5. Competitor Comparison

Compared to similar modules, the Bently Nevada 133323-01 stands out with its dual communication ports (RS485 and Ethernet), supporting both Modbus RTU and TCP/IP protocols simultaneously. It also offers higher temperature resilience (-20°C to +70°C) and modular scalability, allowing users to add channels without replacing the entire system.

Bently 133323-01

6. Selection Recommendations

- Compatibility: Ensure alignment with existing 3500 series racks and software.

- Installation Environment: Verify temperature and humidity conditions match the module’s specifications.

- Budget: Balance upfront costs with long-term savings from predictive maintenance enabled by real-time data.

7. Precautions

- Installation: Follow safety guidelines to avoid electrostatic discharge; use grounding straps when handling.

- Firmware Updates: Regularly update firmware to access new features and bug fixes.

- Redundancy: Consider dual-module setups for critical applications to prevent single points of failure.