Description

1. Product Description

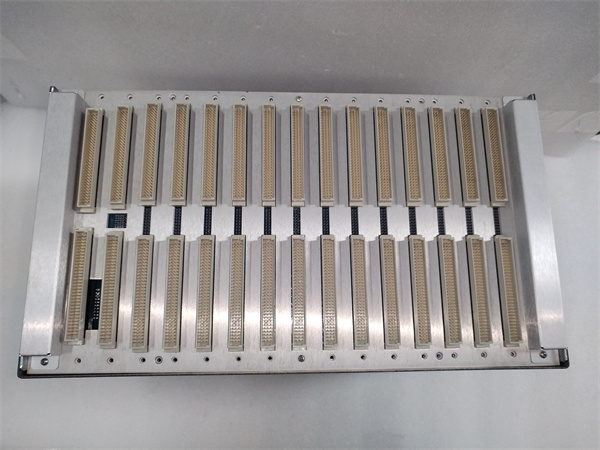

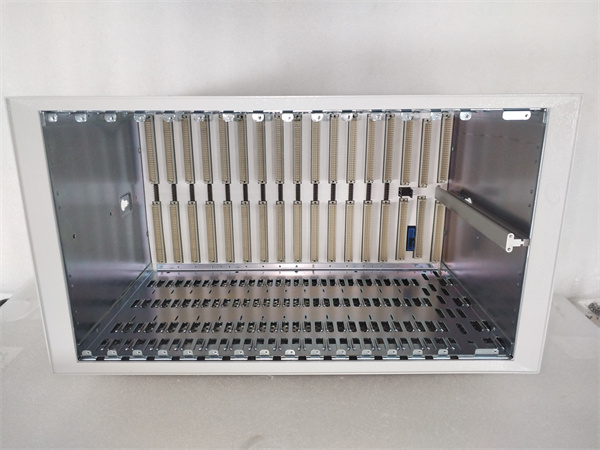

The BENTLY 3500/05-01-02-00-00-00 is a high-performance system rack designed for the BENTLY 3500 Machinery Protection System, serving as the core platform for monitoring and safeguarding critical rotating equipment in industrial environments. As part of the 3500 series, this model provides a robust framework to integrate various monitoring modules, power supplies, and communication gateways, ensuring seamless coordination for real-time data acquisition and analysis.

Engineered for durability and flexibility, the BENTLY 3500/05-01-02-00-00-00 supports up to 14 modules, including vibration monitors, temperature sensors, and relay modules, making it ideal for complex machinery health management systems. Its 19-inch EIA rack-mount design allows easy installation in control panels or industrial enclosures, while the modular architecture enables quick upgrades or replacements without system downtime. The rack’s universal power supply (100–240 V AC) and wide operating temperature range (-40°C to +70°C) ensure reliable performance in harsh conditions, including extreme temperatures and high electromagnetic interference environments.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | 3500/05-01-02-00-00-00 |

| Brand | BENTLY |

| System Type | Machinery Protection System Frame Assembly |

| Power Supply | 100–240 V AC, 50/60 Hz, 20 W maximum |

| Dimensions (W x H x D) | 17.78 cm x 48.26 cm x 30.48 cm (7 x 19 x 12 inches) |

| Weight | Approximately 4.5 kg (10 lbs) |

| Operating Temperature | -40°C to +70°C (-40°F to +158°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Module Slots | 14 slots (including power supply and communication slots) |

| Compatibility | All BENTLY 3500 series monitoring modules |

| Communication Interfaces | Serial (RS-232/485), Ethernet (10/100 Mbps) |

BENTLY 3500/05-01-02-00-00-00

3. Advantages and Features

The BENTLY 3500/05-01-02-00-00-00 offers several key advantages that distinguish it in industrial monitoring applications:

- Modular Design: The 14-slot configuration allows users to customize the system by adding or replacing modules without shutting down the entire system, reducing maintenance costs and downtime.

- Wide Environmental Range: Operates efficiently in extreme temperatures (-40°C to +70°C) and high-vibration environments, ensuring reliability in oil refineries, power plants, and offshore platforms.

- Redundancy Support: Supports dual power supplies and redundant communication paths, enhancing system resilience in mission-critical operations.

- CE Compliance: Meets European safety and environmental standards, making it suitable for global installations.

- Ease of Integration: Seamless compatibility with the entire 3500 series ecosystem, including vibration, temperature, and speed monitoring modules.

4. Application Areas and Case Studies

The BENTLY 3500/05-01-02-00-00-00 is widely used in industries requiring precise machinery health monitoring, including:

- Power Generation: Monitoring steam turbines, generators, and pumps in coal, gas, and nuclear power plants.

- Oil and Gas: Ensuring reliability of compressors, pumps, and motors in offshore platforms and refineries.

- Manufacturing: Tracking the health of conveyor systems, motors, and production equipment in automotive and chemical plants.

Case Study: A major petrochemical plant in the Middle East integrated the BENTLY 3500/05-01-02-00-00-00 with vibration and temperature modules to monitor their critical compressors. The system detected an early-stage bearing failure in a compressor, allowing scheduled maintenance and preventing a potential shutdown that could have caused $2 million in losses.

5. Competitive Comparison

Compared to similar frame assemblies in the market, the BENTLY 3500/05-01-02-00-00-00 stands out through:

- Superior Compatibility: Seamless integration with the entire 3500 series ecosystem, offering more module options than many competing systems.

- Wide Temperature Range: Operational capability in extreme environments, outperforming alternatives with narrower temperature specifications.

- Ease of Expansion: The 14-slot design provides ample room for future upgrades, making it a cost-effective long-term solution.

BENTLY 3500/05-01-02-00-00-00

6. Selection Recommendations

When selecting the BENTLY 3500/05-01-02-00-00-00, consider the following:

- System Requirements: Evaluate the number of monitoring parameters and modules needed to ensure the frame has sufficient slots for current and future needs.

- Environmental Conditions: Confirm that the operating temperature, humidity, and vibration levels of your facility fall within the product’s specifications.

- Budget and Scalability: While the modular design offers flexibility, factor in the cost of additional modules and whether the frame’s expansion capacity aligns with your long-term plans.

7. Precautions

To ensure optimal performance and safety when using the BENTLY 3500/05-01-02-00-00-00:

- Power Safety: Always disconnect the power supply before installing or removing modules to prevent electrical hazards.

- Static Protection: Use anti-static wrist straps and mats when handling internal components to avoid damage from electrostatic discharge.

- Regular Maintenance: Schedule periodic inspections to clean dust and debris from the frame and check for loose connections, especially in high-vibration environments.

- Software Compatibility: Ensure that the firmware and configuration software are up to date to maintain full functionality with all connected modules.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.