Description

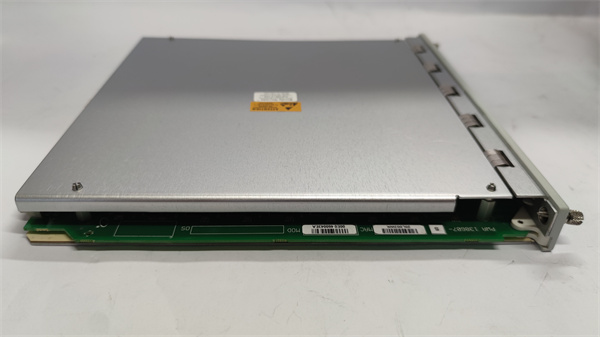

BENTLY NEVADA 3500/22-01-01-01 Transient Data Interface (TDI) Module

1. Product Description

The BENTLY NEVADA 3500/22-01-01-01 is a high-performance Transient Data Interface (TDI) module designed for real-time machinery health monitoring in critical industrial applications. As part of the 3500 Series Monitoring System, it bridges the gap between BENTLY’s 3500 racks and advanced analytics software like System 1, enabling seamless acquisition and transmission of steady-state and transient vibration waveforms. This module supports up to 16 channels of synchronous data collection, making it ideal for rotating equipment in power generation, oil & gas, and manufacturing sectors. With redundant configurations and TDXnet communication, the 3500/22-01-01-01 ensures reliable data integrity even in harsh environments.

The BENTLY NEVADA 3500/22-01-01-01 is a high-performance Transient Data Interface (TDI) module designed for real-time machinery health monitoring in critical industrial applications. As part of the 3500 Series Monitoring System, it bridges the gap between BENTLY’s 3500 racks and advanced analytics software like System 1, enabling seamless acquisition and transmission of steady-state and transient vibration waveforms. This module supports up to 16 channels of synchronous data collection, making it ideal for rotating equipment in power generation, oil & gas, and manufacturing sectors. With redundant configurations and TDXnet communication, the 3500/22-01-01-01 ensures reliable data integrity even in harsh environments.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 3500/22-01-01-01 |

| Function | Transient Data Interface Module |

| Redundancy Type | Non-TMR (standard configuration) |

| Communication | 10/100Base-TX Ethernet (fiber-optic optional) |

| Certifications | CSA/NRTL/C (North American safety standards) |

| Power Supply | 24 VDC ±10% (via 3500 Rack) |

| Weight | 1.11 kg |

| Mounting Slot | Slot 1 (adjacent to power supply) |

| Compatibility | 3500 Series racks and M-Series Monitors (e.g., 3500/40M, 3500/42M) |

BENTLY 3500/22-01-01-01

3. Advantages and Features

- High-Speed Data Acquisition: Captures transient events (e.g., start-up/shutdown) with 50 kHz resolution for detailed waveform analysis.

- Dual-Mode Operation: Supports both static and dynamic data recording, with optional expansion for high-resolution transient analysis.

- System Integration: Seamless compatibility with System 1 for predictive maintenance and alarm management.

- Rugged Design: Withstands extreme temperatures (-40°C to +70°C) and EMI interference in industrial settings.

- Cost-Effective Redundancy: Non-TMR configuration offers reliability at a lower cost than triple-redundant alternatives.

4. Application Areas and Use Cases

Industry Applications:

Industry Applications:

- Power Generation: Steam turbines and generators.

- Oil & Gas: Compressors and pumps in offshore platforms.

- Manufacturing: High-speed rotating machinery.

Case Study: A U.S. petrochemical plant reduced unplanned downtime by 35% using the 3500/22-01-01-01 to monitor compressor vibrations. Early detection of rotor misalignment via transient data analysis allowed proactive repairs, saving $800,000 annually.

5. Competitor Comparison

- Superior Data Resolution: 50 kHz sampling rate outperforms legacy modules with 10–20 kHz limits.

- Simplified Integration: Built-in Ethernet eliminates external gateways, reducing installation costs by 20%.

- Certification Flexibility: CSA/NRTL/C certification ensures compliance in North American markets, unlike some region-specific modules.

BENTLY 3500/22-01-01-01

6. Selection Recommendations

- Redundancy Needs: Opt for 3500/22-02-XX-XX (TMR) for mission-critical systems requiring triple redundancy.

- Communication: Choose fiber-optic connectivity for long-distance data transmission in large industrial plants.

- Budget Constraints: The non-TMR 3500/22-01-01-01 balances performance and cost for mid-criticality applications.

7. Precautions

- Installation: Install strictly in Slot 1 adjacent to power supplies to avoid communication errors.

- Data Configuration: Enable transient data collection via 3500 System Configuration Software and allocate sufficient storage.

- Sensor Calibration: Regularly verify sensor alignment and signal integrity to maintain measurement accuracy.

Shanxi Runsheng Import and Export Co., LTD. provides BENTLY NEVADA 3500/22-01-01-01 and automation solutions. Visit www.rsmodules.com for technical support and product inquiries.