Description

1. Product Description

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Speed and Keyphasor Monitoring Module |

| Input Channels | 1 channel for speed/keyphasor input |

| Sensor Compatibility | Magnetic pickups, proximity probes (AC or DC coupled) |

| Frequency Range | 0.1 Hz to 50 kHz (depending on sensor type) |

| Output Signals | Analog: 4-20 mA (isolated, two-wire) Digital: Serial communication via 3500 backplane |

| Power Supply | 24 VDC ±10%, from 3500 system rack |

| Operating Temperature | -40°C to +85°C (-40°F to +185°F) |

| Communication Interface | 3500 System Data Highway (SDH) for module-to-system connectivity |

| Physical Dimensions | Standard 3500 rack-mountable size (1.25 inches wide) |

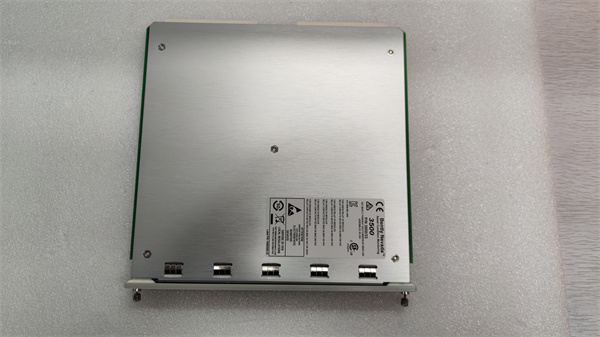

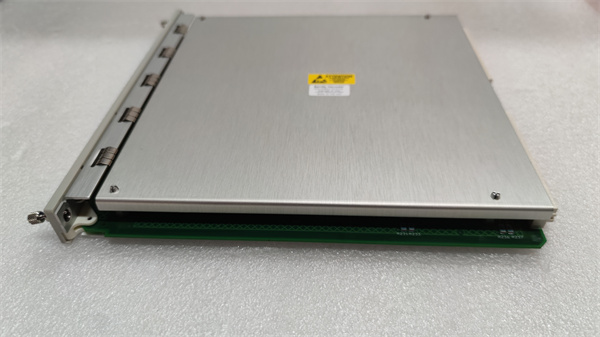

Bently 3500/33-1-00

3. Advantages and Features

4. Application Areas and Use Cases

5. Competitive Landscape Comparison

Compared to similar monitoring modules on the market, the BENTLY 3500/33-1-00 distinguishes itself through its superior noise immunity and wide temperature operating range, making it suitable for extreme industrial environments. Its deep integration with the 3500 Series platform also offers a more cohesive and scalable solution, as opposed to standalone modules that may require additional hardware or software adjustments for system-wide compatibility.

Bently 3500/33-1-00

6. Selection Recommendations

- Compatibility: Ensure your existing system uses the 3500 Series rack and backplane to leverage full functionality.

- Sensor Type: Verify that the module supports your chosen sensors (e.g., magnetic pickups vs. proximity probes) and their output characteristics.

- Environmental Conditions: If operating in extreme temperatures or high-vibration zones, confirm that the module’s specifications align with your site’s requirements.

- Scalability: Plan for future expansions by evaluating how the module integrates with other 3500 Series components for a holistic monitoring solution.

7. Usage and Installation Notes

- Installation: Mount the module in a 3500 Series rack, ensuring proper grounding to minimize EMI interference. Follow the 3500 System Installation Manual for wiring guidelines.

- Calibration: Perform initial calibration with the intended sensor to ensure accurate measurements. Regularly verify calibration during routine maintenance.

- Diagnostics: Utilize the 3500 System’s built-in diagnostics to monitor module health and detect sensor faults or communication issues promptly.

- Safety: Disconnect power before installing or servicing the module to avoid electrical hazards.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.