Description

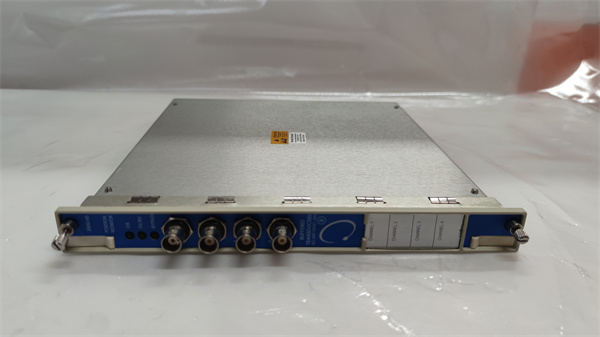

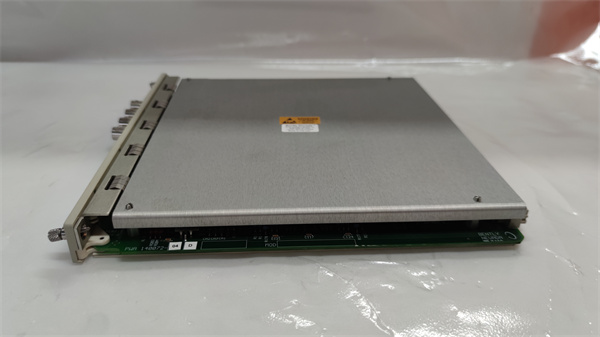

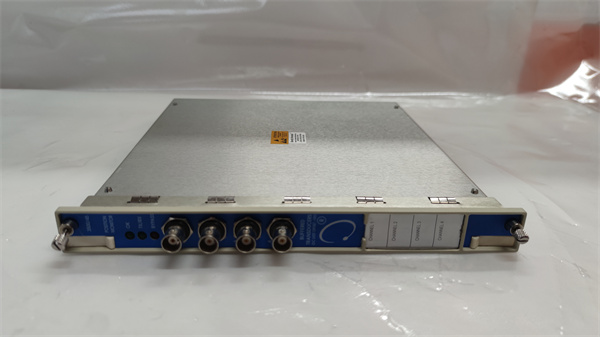

BENTLY NEVADA 3500/45-01-00 Position Monitor

1. Product Description

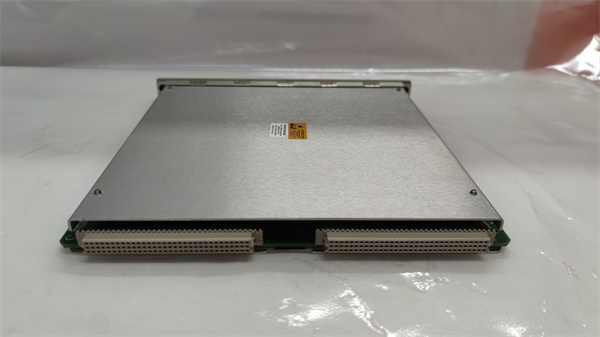

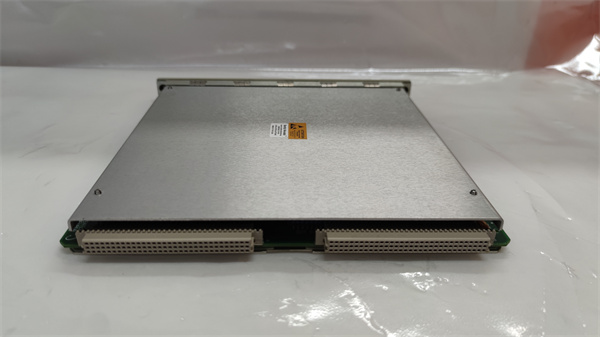

The BENTLY NEVADA 3500/45-01-00 is a 4-channel position monitor designed for rotating machinery, providing continuous monitoring of axial (thrust) position, differential expansion, and other critical parameters. It supports inputs from proximity sensors, rotary position transducers (RPTs), and linear variable differential transformers (LVDTs), enabling versatile applications in power plants, manufacturing, and oil & gas industries. The monitor features advanced signal conditioning, user-programmable alarms, and modular integration with BENTLY’s 3500 Series rack systems. Its compact design and rugged construction ensure reliable performance in harsh environments, while real-time data analysis helps prevent equipment failures.

The BENTLY NEVADA 3500/45-01-00 is a 4-channel position monitor designed for rotating machinery, providing continuous monitoring of axial (thrust) position, differential expansion, and other critical parameters. It supports inputs from proximity sensors, rotary position transducers (RPTs), and linear variable differential transformers (LVDTs), enabling versatile applications in power plants, manufacturing, and oil & gas industries. The monitor features advanced signal conditioning, user-programmable alarms, and modular integration with BENTLY’s 3500 Series rack systems. Its compact design and rugged construction ensure reliable performance in harsh environments, while real-time data analysis helps prevent equipment failures.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 3500/45-01-00 |

| Function | Axial position, differential expansion, case expansion |

| Input Voltage | 24 VDC ±10% |

| Temperature Range | -30°C to +65°C (operating); -40°C to +85°C (storage) |

| Humidity | 95% non-condensing |

| Sensor Compatibility | Proximity sensors, RPTs, LVDTs |

| Channels | 4 (configurable in pairs) |

| Output Signal | 4–20 mA analog, dual relay alarms |

| Dimensions | 24.13 cm × 2.44 cm × 24.18 cm |

| Weight | 0.91 kg |

| Rack Space | 1 full-height slot |

BENTLY 3500/45-01-00

3. Advantages and Features

- Multi-Function Flexibility: Configurable for axial position, differential expansion, or case expansion, supporting up to two functions simultaneously.

- Non-Latching Alarms: Alarms reset automatically once parameters return to safe levels, reducing false triggers.

- Hot-Swap Capability: Modules can be replaced without system shutdown.

- Wide Sensor Support: Compatible with proximity, RPT, and LVDT sensors for diverse monitoring needs.

- CE/UL Certified: Meets global safety standards for industrial use.

4. Application Areas and Use Cases

Industry Applications:

Industry Applications:

- Power Generation: Steam turbines, generators.

- Manufacturing: CNC machines, pumps, compressors.

- Oil & Gas: Centrifugal compressors, rotating equipment.

Case Study: A U.S. power plant reduced unplanned downtime by 25% using the 3500/45-01-00 to monitor axial displacement in steam turbines, avoiding $800,000 in annual repair costs.

5. Competitor Comparison

- Higher Channel Density: Four configurable channels compared to typical 2-channel alternatives.

- Simplified Configuration: Built-in software eliminates the need for external programming tools.

- Extended Temperature Range: Operates at -30°C to +65°C, exceeding most competitors’ 0°C–50°C range.

BENTLY 3500/45-01-00

6. Selection Recommendations

- Monitoring Complexity: Choose the 3500/45-01-00 for multi-parameter applications; opt for BENTLY’s 3500/42M for single-channel vibration monitoring.

- Environment: Ensure compatibility with ambient temperatures and humidity levels.

- Scalability: Pair with BENTLY’s System 1 software for enterprise-wide asset management.

7. Precautions

- Sensor Alignment: Properly align proximity sensors to avoid measurement errors.

- Channel Pairing: Configure channels in pairs (e.g., Channels 1+2 for axial position, 3+4 for differential expansion).

- Safety Barriers: Use external barriers for hazardous areas if internal options are not selected.

Shanxi Runsheng Import and Export Co., LTD. provides BENTLY NEVADA 3500/45-01-00 and automation solutions. Visit www.rsmodules.com for technical support and product inquiries.