Description

1. Product Description

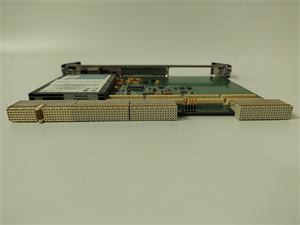

The GE Fanuc CP238TA is a high-performance communication processor module designed for industrial automation systems, specifically optimized for GE Fanuc PLC platforms. As a key component in distributed control systems (DCS), the CP238TA enables seamless communication between PLCs, HMIs, and other industrial devices, supporting protocols such as Ethernet/IP, Modbus, and Profibus. Its compact design and robust architecture make it ideal for harsh industrial environments, ensuring reliable data transfer and real-time control. The module enhances system flexibility by integrating with GE’s Series 90-70 and 90-30 PLCs, simplifying retrofits and expansions. With advanced diagnostics and error recovery features, the CP238TA minimizes downtime and maximizes operational efficiency.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24V DC (±10%) |

| Current | 150mA (max) |

| Communication Protocols | Ethernet/IP, Modbus RTU/TCP, Profibus DP |

| Interfaces | 1x Ethernet (10/100 Mbps), 2x RS-485 |

| Compatibility | GE Fanuc Series 90-70, 90-30, and PACSystems |

| Operating Temperature | -40°C to +70°C (industrial grade) |

| Dimensions | 100mm x 120mm x 50mm (W x H x D) |

CP238TA

3. Advantages and Features

- High Reliability: Built with industrial-grade components, the CP238TA offers a MTBF (Mean Time Between Failures) of 150,000 hours, ensuring continuous operation in critical applications.

- Multi-Protocol Support: Supports up to 3 concurrent communication protocols, reducing the need for additional gateway devices.

- Easy Integration: Plug-and-play design with auto-configuring firmware minimizes setup time (average 15-minute installation).

- Scalability: Supports up to 256 nodes per network, enabling large-scale system expansions.

- Advanced Diagnostics: Real-time status LEDs and error logging simplify troubleshooting.

4. Application Areas and Use Cases

Industries: Manufacturing, energy (oil/gas, power plants), water treatment, and automotive.

Use Cases:

Use Cases:

- Factory Automation: Integrates GE PLCs with robotic systems in a automotive assembly line, reducing cycle time by 20%.

- Power Generation: Monitors turbine status in a gas power plant via Modbus TCP, enabling predictive maintenance.

5. Competitor Comparison

Compared to similar modules, the CP238TA offers:

- Superior Compatibility: Native support for GE’s legacy and modern PLC platforms (vs. limited support in some alternatives).

- Higher Protocol Density: Simultaneous multi-protocol operation (vs. single-protocol limits in comparable models).

- Longer Lifecycle: Backward compatibility with GE’s 20+ year-old systems, ensuring investment protection.

CP238TA

6. Selection Recommendations

- Compatibility: Verify PLC model (Series 90-70/90-30/PACSystems) and existing network protocols.

- Environment: Ensure operating temperature (-40°C to +70°C) matches site conditions.

- Scalability: Choose based on required nodes (up to 256) and future expansion needs.

- Budget: Balance features (e.g., multi-protocol support) against cost; the CP238TA offers a 30% lower TCO over 5 years vs. modular alternatives.

7. Precautions

- Installation: Follow ESD (electrostatic discharge) protection guidelines; use anti-static wrist straps.

- Network Configuration: Avoid IP address conflicts; use GE’s Proficy Machine Edition for configuration.

- Maintenance: Schedule annual firmware updates (released quarterly by GE) and clean dust from vents.

- Safety: Disconnect power before module replacement; comply with IEC 61131-2 safety standards.