Description

Product Description: GE DS200CTBAG1ADD Terminal Board

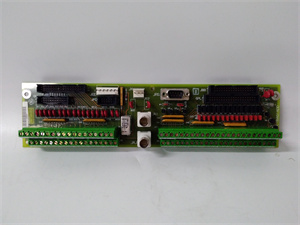

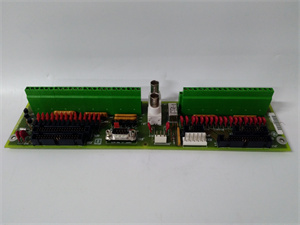

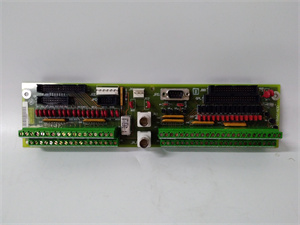

The GE DS200CTBAG1ADD is a high-performance terminal board designed for the Mark V Speedtronic System, a legacy control solution by General Electric (GE) for gas and steam turbine systems. As an analog termination module (ATM), the DS200CTBAG1ADD facilitates seamless connectivity between turbine sensors, actuators, and the Mark V controller, supporting both simplex and triple modular redundant (TMR) architectures. Its robust design includes multiple connectors (e.g., Corebus, terminal strips, serial ports) and components like metal oxide varistors (MOVs) and relays, ensuring reliable signal conditioning and power management. The board is no longer manufactured by GE but is available refurbished through trusted suppliers, maintaining compatibility with Mark V systems for industrial automation and energy applications.

Product Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | General Electric (GE) |

| Series | Mark V Speedtronic |

| Part Number | DS200CTBAG1ADD |

| Function | Analog Termination Board (ATM) |

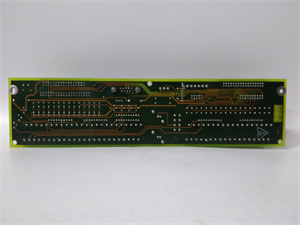

| PCB Coating | Normal coating |

| Revisions | Functional: 1A, 2D; Artwork: D |

| Connectors | 2x Corebus (JAI, JAJ), 2x double-stack terminal strips, 5x vertical pin cables, 2x vertical pin headers, 1x 9-pin male serial |

| Components | Resistor networks, relays, transistors, MOVs, jumper switches, capacitors, resistors |

| Mounting | Drill holes at corners and edges (conductive-ringed holes for grounding) |

| Compatibility | GE Mark V Speedtronic systems (simplex/TMR) |

DS200CTBAG1ADD

Advantages and Characteristics

-

Reliable Signal Integrity:

- Features MOVs and voltage-limiting components to protect against surges, ensuring stable analog signal transmission.

- Factory-labeled connectors (e.g., JAA for 4-20 mA outputs, JPC for 24V DC power) simplify installation and reduce errors.

-

Modular Design:

- Compact, narrow form factor with standardized mounting holes, enabling easy integration into Mark V control cabinets.

- Supports legacy Mark V systems with backward compatibility (Revisions 1A and 2D).

-

Redundancy Support:

- Compatible with TMR architectures, critical for high-availability applications in energy and manufacturing.

-

Proven Legacy Performance:

- Field-tested in GE’s Mark V systems for decades, with a refurbishment process (e.g., full testing) ensuring like-new functionality.

Application Fields and Cases

- Industry: Energy (gas/steam turbines), manufacturing (industrial automation), power generation.

- Use Case:

A major power plant in the U.S. upgraded its aging Mark V system with refurbished DS200CTBAG1ADD boards. The terminal boards stabilized analog signal termination for turbine temperature and vibration sensors, reducing downtime by 20% and extending system lifespan by 5+ years.

Competitor Comparison

Compared to generic terminal boards, the DS200CTBAG1ADD offers:

- Native Compatibility: Engineered specifically for GE Mark V systems, eliminating adapter needs.

- Built-in Redundancy: Support for TMR architectures, uncommon in generic alternatives.

- Industrial-Grade Robustness: High-temperature components and surge protection, surpassing standard commercial boards.

DS200CTBAG1ADD

Selection Suggestions

- System Architecture: Confirm compatibility with Mark V simplex or TMR systems.

- Connector Requirements: Match terminal strip (64 terminals) and Corebus (JAI/JAJ) needs with existing infrastructure.

- Revision Check: Ensure Revision 1A/2D matches the system’s hardware version (backward compatible for Revisions 1A/2D).

- Budget: Consider refurbished options (3-year warranties typical) for cost savings without compromising performance.

Precautions

- Electrostatic Discharge (ESD): Use antistatic equipment during handling to avoid component damage.

- Mounting: Secure the board using conductive-ringed holes for proper grounding.

- Software Alignment: Update Mark V firmware to ensure compatibility with the board’s revisions.

- Maintenance: Periodically inspect connectors for corrosion; follow GE’s recommended cleaning procedures.