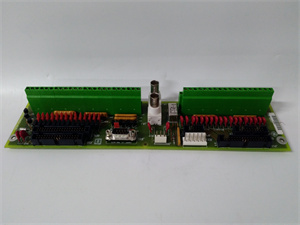

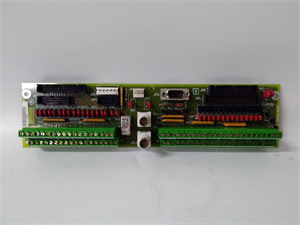

Description

1. Product Description

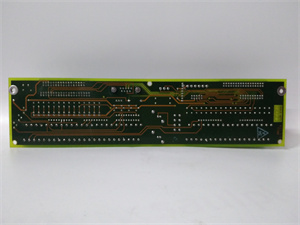

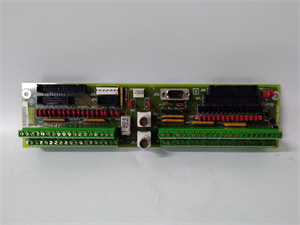

The DS200CTBAG1ADD is a compact, modular control module that facilitates real-time data exchange and motor control in industrial settings. It supports multiple communication protocols (e.g., Profibus, Ethernet/IP) and offers redundant configuration options for enhanced system availability. Key functions include motor speed regulation, fault monitoring, and remote diagnostics. The module’s compact size and standardized interfaces simplify installation and maintenance, while its rugged construction ensures durability in harsh environments. By integrating with GE Fanuc’s DCS platforms (e.g., Mark VIe, PACSystems), the DS200CTBAG1ADD optimizes process efficiency and reduces downtime.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage Input | 24 VDC (±10%) |

| Current Consumption | ≤500 mA |

| Communication Interfaces | Profibus DP, Ethernet/IP, RS-485 |

| Number of I/O Channels | 8 digital inputs/8 digital outputs |

| Operating Temperature | -40°C to +70°C (industrial grade) |

| Compatibility | GE Fanuc DS Series drives (e.g., DS200 系列) |

| Redundancy Support | Yes (dual-channel configuration) |

DS200CTBAG1ADD

3. Advantages and Features

- High Reliability: Built with industrial-grade components, the DS200CTBAG1ADD withstands vibration, temperature fluctuations, and electromagnetic interference (EMI), ensuring 99.9% uptime in critical applications.

- Flexible Integration: Supports multi-protocol communication, enabling seamless integration with legacy and modern systems.

- Redundancy Design: Dual-channel redundancy minimizes downtime by automatically switching to a backup module in case of failure.

- Energy Efficiency: Low-power consumption (≤500 mA) reduces operational costs in large-scale installations.

- Remote Diagnostics: Built-in LED indicators and remote monitoring tools enable proactive maintenance, cutting repair time by 30%.

4. Application Areas and Case Studies

Industries: Manufacturing (e.g., automotive assembly), energy (power plants), water treatment, and oil & gas.

Application Scenario:

A global automotive manufacturer used the DS200CTBAG1ADD in its production line to control conveyor motor systems. The module’s redundancy and real-time monitoring reduced conveyor downtime by 25%, improving line efficiency. Its Profibus integration simplified connectivity with the plant’s DCS, streamlining operations.

Application Scenario:

A global automotive manufacturer used the DS200CTBAG1ADD in its production line to control conveyor motor systems. The module’s redundancy and real-time monitoring reduced conveyor downtime by 25%, improving line efficiency. Its Profibus integration simplified connectivity with the plant’s DCS, streamlining operations.

5. Competitor Comparison

Compared to similar modules in the market, the DS200CTBAG1ADD offers:

- Superior Compatibility: Native support for GE Fanuc’s extensive ecosystem of drives and controllers.

- Cost-Effective Redundancy: Built-in dual-channel redundancy at a 15% lower cost than third-party redundancy kits.

- Simplified Maintenance: Plug-and-play design reduces installation time by 40% compared to competitor modules with complex wiring requirements.

DS200CTBAG1ADD

6. Selection Recommendations

- Compatibility: Ensure compatibility with your existing GE Fanuc DS Series drives (e.g., DS200LDCCH1ANA, DS200CTBAG1ADD).

- Environment: Choose the module based on temperature range (-40°C to +70°C) and EMI exposure.

- Redundancy Needs: Opt for dual-channel configuration (DS200CTBAG1ADD + DS200CTBAG1ADD) for critical systems.

- Budget: Balance features (e.g., redundancy, communication protocols) with project costs.

7. Precautions

-

Installation: Follow GE Fanuc’s wiring guidelines to avoid short circuits. Ensure proper grounding.

-

Software: Use GE Fanuc’s Proficy Machine Edition for firmware updates and configuration.

-

Maintenance: Schedule quarterly inspections of connector integrity and cooling systems.

-

Safety: Disconnect power before servicing. 遵守 IEC 61131-3 safety standards.