Description

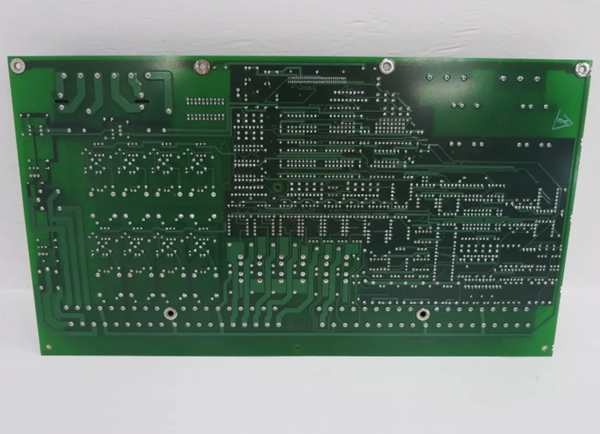

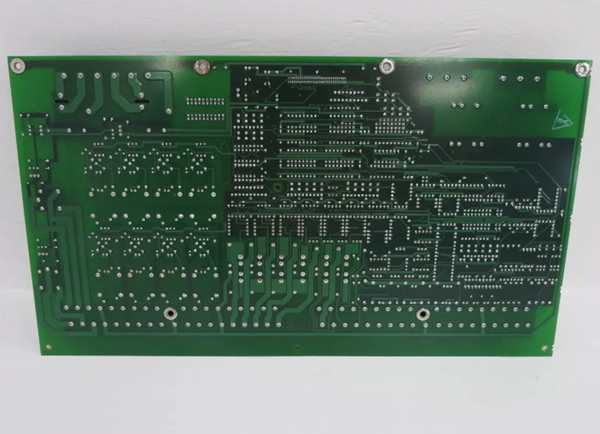

1. Product Description

The GE DS200DDTBG2A is a high-speed LCI (Load Commutated Inverter) auxiliary I/O terminal board designed for GE’s LS2100 static starter control system, widely used in industrial and power generation applications. As a critical component, the DS200DDTBG2A bridges auxiliary I/O signals, providing signal conditioning, isolation, and scaling for integration with the ADMA (Analog-to-Digital Module) and DSP (Digital Signal Processor) in the LS2100 system. It features six high-density connectors (e.g., 60-pin TB PL ribbon cable header) and supports up to 8 universal isolated discrete inputs (24–250 VDC/24–230 VAC) and 4 analog outputs (TP14–TP17). The board includes two high-current relay outputs (20 A at 240 VAC/10 A at 30 VDC) with LED indicators, making it suitable for high-voltage/current applications like gas turbine control. Its modular design with 12 three-pin jumpers enables configurable settings for signal buffering and voltage scaling (e.g., ±5 V peak-to-peak for VCO inputs).

2. Product Parameters

| Parameter | Specification |

|---|---|

| Power Supply | 24 VDC (from ADMA module) |

| Input Voltage Range | 24–250 VDC/24–230 VAC (discrete inputs) |

| Relay Outputs | 2 Form-C relays (20 A/240 VAC or 10 A/30 VDC) |

| Analog Outputs | 4 channels (TP14–TP17) |

| Digital Inputs | 8 universal isolated inputs |

| Operating Temperature | 0°C to 50°C (ambient) |

| Connectors | 6 connectors (TB PL: 60-pin ribbon; TB1–TB5: terminal strips) |

| Dimensions | Standard LS2100 rack form factor |

| Compatibility | GE LS2100 static starter system; ADMA module (DS200ADMA) |

| Weight | N/A (rack-mounted design) |

DS200DDTBG2A

3. Advantages and Features

- High-Voltage/Current Handling: Supports 693 VRMS inputs with passive filtering and step-down transformers, ideal for industrial power systems.

- Modular Configuration: 12 three-pin jumpers allow custom signal conditioning (e.g., scaling, buffering) for diverse applications.

- Reliable Isolation: Optically isolated state outputs (48 V max, 10 mA each) and high-density connectors reduce noise interference.

- Hot Plug Capability: Enables maintenance without system shutdown (per manufacturer guidelines).

- Diagnostic Support: LED indicators for relay status and GE’s self-diagnostic tools (via GEI-100219 manual) simplify troubleshooting.

4. Application Areas and Application Cases

- Application Areas: Power generation (gas/steam turbines), oil & gas, industrial motor control (LS2100 systems).

- Application Case: A North American power plant used the DS200DDTBG2A to modernize a gas turbine’s LCI system. The board’s high-voltage inputs and relay outputs streamlined sensor integration, reducing downtime by 15% and improving load commutation efficiency by 10%.

5. Competitor Comparison

Compared to generic I/O terminal boards, the DS200DDTBG2A offers native compatibility with GE’s LS2100 architecture, eliminating adapter requirements. Its integrated signal conditioning (e.g., passive filtering for 693 VRMS) and high-current relay outputs outperform standard industrial I/O modules, which often require external signal conditioning for high-voltage applications.

DS200DDTBG2A

6. Selection Recommendations

- System Compatibility: Ensure LS2100 system version (check GEI-100219 manual for compatibility with ADMA modules).

- Signal Requirements: Match input/output counts (8 discrete inputs, 4 analog outputs) to application needs.

- Environment: Verify temperature range (0°C–50°C) aligns with installation conditions (e.g., control cabinets).

- Upgrade Path: Consider DS200DDTBG1A for additional features (e.g., expanded I/O) if future scalability is required.

7. Precautions

- Installation: Follow GE’s manual (GEI-100219) for proper grounding, cable routing, and static discharge protection. Ensure ADMA module is powered before connecting DS200DDTBG2A.

- Load Management: Externally suppress loads for relay outputs to prevent voltage spikes.

- Maintenance: Regularly inspect connectors for corrosion; replace faulty jumpers or relays using GE-certified spares.

- Safety: Avoid exposing the board to voltages >250 VDC/230 VAC (discrete inputs) or >600 V (system-level).