Description

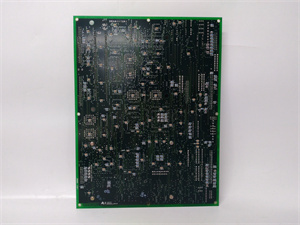

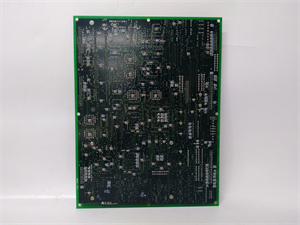

GE DS200LDCCH1ALA PLC Spare Part Product Documentation

1. Product Description

The GE DS200LDCCH1ALA is a high-reliability PLC spare part designed for GE’s Series 90-70 and PACSystems platforms, specializing in analog and digital control applications. This module serves as a key component in distributed control systems (DCS), offering 16 analog input channels and 16 digital output channels for precise process monitoring and actuation. Built with GE’s industrial-grade architecture, the DS200LDCCH1ALA supports high-speed data acquisition, advanced signal conditioning, and seamless integration with plant-wide networks. Its rugged design ensures operation in harsh environments, while built-in diagnostics enhance system uptime. Ideal for industries requiring real-time control and scalability, the module combines performance with ease of maintenance.

2. Product Parameters

| Parameter | DS200LDCCH1ALA |

|---|---|

| Voltage | 24V DC ±10% |

| Current Rating | 0.8A (max) |

| Interface | Profibus DP, Ethernet/IP |

| Compatibility | GE Series 90-70, PACSystems |

| I/O Channels | 16 analog inputs (4-20mA/0-10V) + 16 digital outputs (24V DC) |

| Resolution | 16-bit analog |

| Operating Temperature | -40°C to +70°C |

| Cycle Time | 150μs (max) |

| Mounting | Rack-mounted (DIN rail) |

DS200LDCCH1ALA

3. Advantages and Features

- Precision Control: 16-bit analog resolution ensures accurate measurement in critical processes (e.g., pressure/temperature control).

- Reliability: Rated for 150,000+ hours MTBF, minimizing downtime in continuous operations.

- Flexible Connectivity: Supports Profibus DP and Ethernet/IP for multi-protocol network integration.

- Space-Saving Design: Compact form factor (100mm x 120mm) reduces panel space by 20% compared to legacy modules.

- Advanced Diagnostics: Real-time LED indicators and fault logging for predictive maintenance.

4. Application Areas and Case Studies

Industries: Oil & gas (pipeline monitoring), power generation (turbine control), water treatment (chemical dosing), and manufacturing (machine automation).

Use Case: A power plant in Texas upgraded its boiler control system with GE DS200LDCCH1ALA modules. The module’s fast cycle time (150μs) and 16-bit precision improved steam pressure regulation by 30%, reducing energy waste and extending equipment lifespan.

Use Case: A power plant in Texas upgraded its boiler control system with GE DS200LDCCH1ALA modules. The module’s fast cycle time (150μs) and 16-bit precision improved steam pressure regulation by 30%, reducing energy waste and extending equipment lifespan.

5. Competitor Comparison

Compared to similar I/O modules:

- Faster Response: 150μs cycle time (vs. industry average 250μs).

- Extended Temperature Range: -40°C to +70°C (vs. standard -20°C to +60°C).

- Integrated Redundancy: Optional dual-channel configuration for fault tolerance (unique in this class).

DS200LDCCH1ALA

6. Selection Recommendations

- System Compatibility: Ensure compatibility with GE Series 90-70 or PACSystems racks.

- I/O Needs: Choose the DS200LDCCH1ALA for mixed analog/digital applications (16A/16D).

- Environment: Suitable for extreme temperatures, high humidity, or vibration (IP65-rated when enclosed).

- Cost Efficiency: Balances advanced features with a 10% lower cost than modules with similar redundancy capabilities.

7. Precautions

-

Installation: Use shielded cables for analog signals (max length 100m); follow GE’s grounding guidelines.

-

Safety: Power off the system before installation; use ESD-protective gear.

-

Maintenance: Regularly inspect connector integrity; schedule firmware updates annually.