Description

1. Product Description

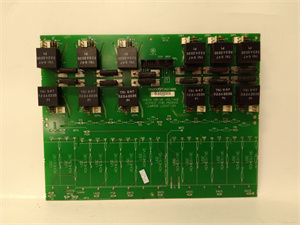

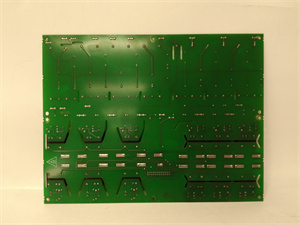

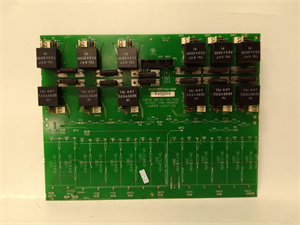

The GE DS200CPCAG1ABB is a high-performance contactor pilot board designed for GE’s Mark V series of turbine control systems. As a critical component in legacy Mark V systems, this board converts 115V AC to 105V DC voltage, enabling precise control of contactors of GE’s speedtronic control system. With a 24V DC 15A socket power relay, four terminal blocks (supporting 12 signal wires), and a rugged PCB coating, the DS200CPCAG1ABB ensures reliable operation in harsh industrial environments. Its legacy design aligns with GE’s patented control technology, making it a trusted choice for retrofitting or maintaining Mark V systems.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Part Number | DS200CPCAG1ABB |

| Manufacturer | GE (General Electric) |

| Series | Mark V |

| Function | Contactor Pilot Board |

| Voltage | Input: 115V AC; Output: 105V DC |

| Relay Rating | 24V DC 15A |

| Connectors | 1x 12-pin, 2x 2-pin |

| Terminal Blocks | 4 (supports 12 signal wires) |

| PCB Coating | Normal (protective coating) |

| Dimensions | 4 x 3.5 inches (10.2 x 8.9 cm) |

| Compatibility | GE Mark V turbine control systems |

DS200PCCAG1ABB

3. Advantages and Features

- Rugged Design: Thick PCB coating and robust components resist wear and environmental stresses.

- Precise Voltage Regulation: Rectifiers, capacitors, and diodes ensure stable 105V DC output for contactor operation.

- Reliable Contactor Control: 115V DC coil voltage keeps contactors closed after initial activation.

- Easy Integration: Standard connectors and terminal blocks simplify installation in Mark V systems.

- Legacy Support: Backward-compatible with GE’s Mark V series, ideal for maintaining older industrial control setups.

4. Application Areas and Cases

Industry Applications:

- Power generation (gas turbines, steam turbines).

- Oil and gas refineries.

- Industrial automation systems.

Case Study:

A power plant in Texas used the DS200CPCAG1ABB to replace a faulty contactor board in its Mark V turbine control system. The board’s voltage regulation and rugged design restored stable operation, reducing downtime by 40% and extending the system’s lifecycle by 5+ years.

A power plant in Texas used the DS200CPCAG1ABB to replace a faulty contactor board in its Mark V turbine control system. The board’s voltage regulation and rugged design restored stable operation, reducing downtime by 40% and extending the system’s lifecycle by 5+ years.

5. Competitive Comparison

Compared to similar legacy contactor boards, the DS200CPCAG1ABB offers:

- Higher voltage tolerance (115V AC input vs. 24V AC in some alternatives).

- Enhanced reliability through GE’s speedtronic technology.

- Direct compatibility with Mark V systems, eliminating retrofit costs.

DS200PCCAG1ABB

6. Selection Recommendations

- Compatibility: Ensure integration with GE Mark V systems (check part number and series compatibility).

- Environment: Verify temperature and humidity ratings for harsh industrial settings.

- Maintenance: Prioritize refurbished units (if new stock is unavailable) with certified testing.

- Budget: Balance cost with long-term reliability—legacy boards like the DS200CPCAG1ABB often offer better ROI than generic alternatives.

7. Precautions

- Installation: Handle the board carefully to avoid damaging the tall 24V DC relay (prone to physical impact).

- Voltage Checks: Ensure input voltage matches specifications (115V AC) to prevent component failure.

- Termination: Use washers when securing screws to avoid PCB cracks. Tighten terminal blocks gently to prevent wire damage.

- Maintenance: Periodically inspect the relay for wear; replace if moving parts show signs of degradation.