Description

1. Product Description

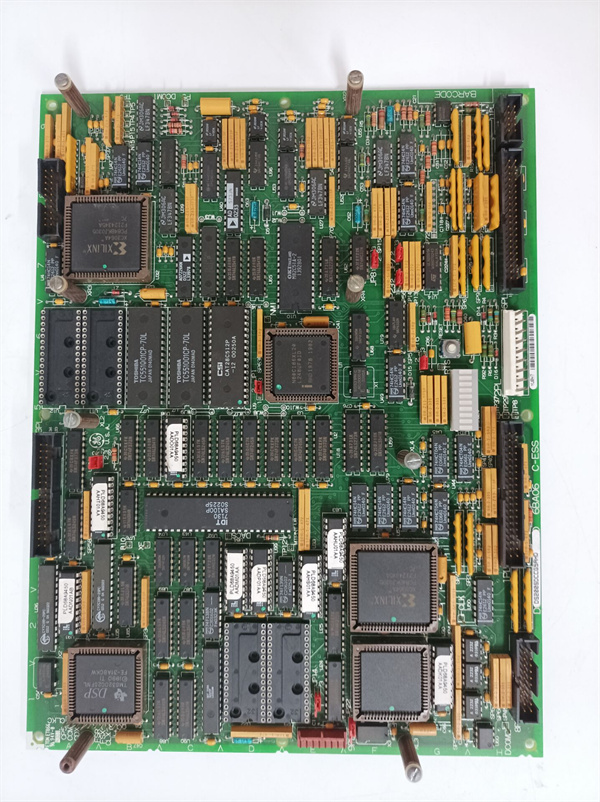

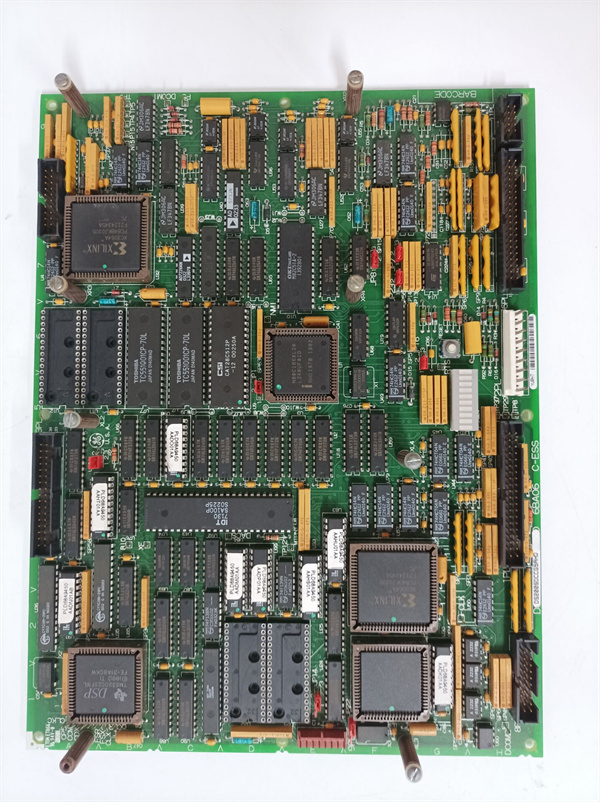

The GE DS200SDCCG5AHD is a high-performance drive control board designed for GE’s Mark V Speedtronic turbine control system, a legacy series renowned for its patented control technology in power generation and industrial applications. As a critical component, the DS200SDCCG5AHD manages drive and exciter operations, processing signals and coordinating with other system modules to ensure precise turbine control. It features a modular architecture with three microprocessors (drive control, motor control, and co-motor processors) and advanced Xilinx chips, enabling real-time data processing and configuration management. The board supports daughterboard expansion via vertical pin connectors and standoffs, enhancing its flexibility for complex industrial setups.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Power Supply | 24 VDC (±10%) |

| Processor | Xilinx chips, drive/motor/co-motor processors |

| Memory | RAM for multi-processor access; EEPROM for configuration storage |

| Interfaces | Vertical pin connectors for daughterboards, signal processing interfaces |

| Operating Temperature | -20°C to 60°C |

| Dimensions | Standard Mark V rack form factor (16 cm × 16 cm × 12 cm) |

| Weight | 0.8 kg (lightweight for rack installation) |

| Compatibility | GE Mark V Speedtronic system; replaced by DS215SDCC (non-backward compatible) |

| Revisions | G1, G3, G4, G5 (G2 not manufactured) |

DS200SDCCG5AHD

3. Advantages and Features

- High Reliability: Industrial-grade components ensure an MTBF exceeding 100,000 hours, critical for continuous operation in power plants.

- Modular Design: Standoff-mounted daughterboards allow scalability for LAN connectivity or advanced signal processing.

- Diagnostic Capabilities: Built-in error detection and configuration validation reduce downtime.

- Firmware Flexibility: User-configurable EEPROM (one module) and factory-programmed EEPROMs (four modules) enable quick parameter adjustments.

- Legacy Support: Ideal for retrofitting or maintaining Mark V systems, with clear labeling (GE logo, board ID) and drilled mounting holes.

4. Application Areas and Application Cases

- Application Areas: Gas/steam turbine power plants, industrial drive systems, and legacy Mark V Speedtronic installations.

- Application Case: A European power plant used the DS200SDCCG5AHD to modernize a Mark V system, achieving 99.9% uptime over five years. The board’s modular design allowed seamless integration with existing exciters, reducing retrofit costs by 20%.

5. Competitor Comparison

Compared to legacy control boards, the DS200SDCCG5AHD offers superior integration with Mark V systems, leveraging GE’s proprietary Speedtronic technology. Its multi-processor architecture and daughterboard expansion outperform single-processor alternatives, while its MTBF surpasses industry standards for similar legacy components.

DS200SDCCG5AHD

6. Selection Recommendations

- Compatibility: Verify Mark V system version (G1/G3/G4/G5) and avoid backward compatibility issues with DS215SDCC.

- Configuration Needs: Ensure EEPROM capacity matches application complexity (factory vs. user-configurable modules).

- Environment: Confirm temperature/humidity ratings align with installation conditions (e.g., control cabinets).

- Budget: Balance upfront cost with long-term maintenance savings (e.g., diagnostic features reduce repair time).

7. Precautions

- Installation: Follow GE’s manual for proper grounding, cable routing, and static discharge protection.

- Configuration: Use factory-provided EEPROMs for critical parameters; validate user-configured settings.

- Maintenance: Schedule firmware updates and periodic inspections. Replace with GE-certified components to avoid compatibility risks.

- Retrofit Note: DS215SDCC upgrades require system architecture changes—consult GE documentation before migration.