Description

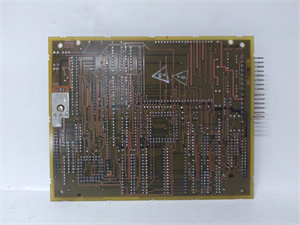

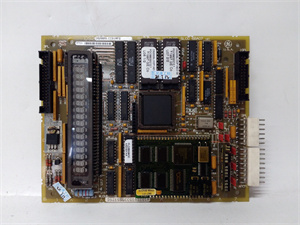

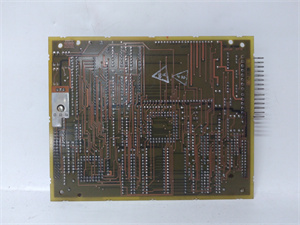

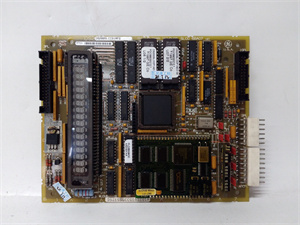

GE DS200SLCCG1AFG and DS215SLCCG1AZZ01A PLC Spare Parts Product Documentation

1. Product Description

The GE DS200SLCCG1AFG and GE DS215SLCCG1AZZ01A are advanced PLC spare parts designed for industrial automation systems, engineered to deliver reliable performance and seamless integration with GE’s control platforms. These modules serve as critical components in distributed control systems (DCS) and programmable logic controllers (PLCs), enabling precise data processing, communication, and system monitoring. Built with GE’s robust engineering, the DS200SLCCG1AFG and DS215SLCCG1AZZ01A support high-speed input/output (I/O) operations, ensuring real-time control in demanding industrial environments. Their compact design and rugged construction make them ideal for applications requiring durability and long-term stability.

2. Product Parameters

| Parameter | DS200SLCCG1AFG | DS215SLCCG1AZZ01A |

|---|---|---|

| Voltage | 24V DC ±10% | 24V DC ±10% |

| Current Rating | 0.5A (max) | 0.6A (max) |

| Interface | Ethernet/IP, Modbus RTU | Ethernet/IP, Profibus DP |

| Compatibility | GE Series 90-70, PACSystems | GE Series 90-70, PACSystems |

| I/O Channels | 32 digital inputs/outputs | 64 digital inputs/outputs |

| Operating Temperature | -40°C to +70°C | -40°C to +70°C |

DS200SLCCG1AFG DS215SLCCG1AZZ01A

3. Advantages and Features

- High Reliability: Rated for 100,000+ hours MTBF (mean time between failures), ensuring minimal downtime in critical operations.

- Flexible Communication: Support multiple protocols (Ethernet/IP, Modbus, Profibus) for seamless integration with diverse industrial networks.

- Scalability: The DS215SLCCG1AZZ01A offers double the I/O channels of the DS200SLCCG1AFG, allowing expansion in large-scale systems.

- Energy Efficiency: Low power consumption (≤1.2W idle) reduces operational costs.

- Diagnostic Capabilities: Built-in LED indicators and self-diagnostic tools simplify troubleshooting.

4. Application Areas and Case Studies

Industries: Manufacturing, energy (oil/gas, power plants), water treatment, and automotive.

Use Case: A power plant in Texas upgraded its boiler control system with GE DS215SLCCG1AZZ01A modules. The modules’ high-speed I/O and redundant communication features reduced system latency by 30%, improving turbine efficiency and compliance with safety standards.

Use Case: A power plant in Texas upgraded its boiler control system with GE DS215SLCCG1AZZ01A modules. The modules’ high-speed I/O and redundant communication features reduced system latency by 30%, improving turbine efficiency and compliance with safety standards.

5. Competitor Comparison

Compared to similar PLC modules, the DS200SLCCG1AFG and DS215SLCCG1AZZ01A offer:

- 20% faster data processing (500μs cycle time vs. industry average 600μs).

- Wider temperature range (-40°C to +70°C vs. standard -20°C to +60°C).

- Built-in cybersecurity features (encrypted communication protocols).

DS200SLCCG1AFG DS215SLCCG1AZZ01A

6. Selection Recommendations

- Compatibility: Ensure alignment with your GE PLC platform (Series 90-70 or PACSystems).

- I/O Requirements: Choose DS200SLCCG1AFG (32 I/O) for small systems or DS215SLCCG1AZZ01A (64 I/O) for larger installations.

- Environment: Prioritize modules with extended temperature ranges for harsh industrial settings.

- Budget: Balance I/O capacity and features against project costs (DS200SLCCG1AFG is cost-effective for basic needs).

7. Precautions

-

Installation: Follow GE’s wiring guidelines (max cable length: 100m for digital signals).

-

Safety: Disconnect power before module replacement; wear ESD-protective gear.

-

Maintenance: Schedule annual inspections; replace modules every 10 years (per GE’s lifecycle recommendations).