Description

Product Description: GE 04220FL11232A

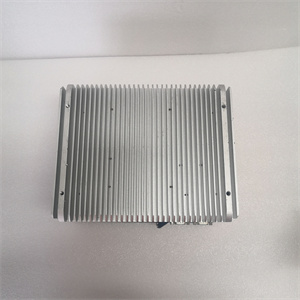

The GE 04220FL11232A is a high-performance industrial controller module designed for automation systems, offering robust processing capabilities and seamless integration with industrial networks. As part of GE’s Intelligent Platforms series, the 04220FL11232A serves as a critical component for real-time data processing, machine control, and communication in harsh industrial environments. Its compact design and advanced features make it suitable for applications ranging from manufacturing lines to power generation systems. Key functionalities include high-speed data acquisition, modular I/O configuration, and support for multiple communication protocols, ensuring reliable operation in diverse industrial settings.

Product Parameters

| Parameter | Specification |

|---|---|

| Processor | 1.4 GHz Celeron (32-bit microprocessor) |

| Memory | 2 GB RAM, 32 MB Flash ROM |

| Operating System | GE’s RTX real-time operating system |

| Communication Interfaces | Ethernet, RS-485, CANopen |

| Power Supply | 24 VDC (±10%) or 120/240 VAC (model-dependent) |

| Power Consumption | 25 W (max) |

| Operating Temperature | -20°C to +55°C |

| Enclosure Rating | IP20 (non-flameproof) |

| Dimensions | 140 mm x 100 mm x 40 mm |

| Weight | 0.5 kg |

GE 04220FL11232A

Advantages and Features

- High-Performance Processing: The 04220FL11232A features a 1.4 GHz Celeron processor and 2 GB RAM, enabling rapid data processing and sub-millisecond cycle times for real-time control.

- Versatile Connectivity: Supports Ethernet, RS-485, and CANopen interfaces, facilitating seamless integration with PLCs, HMIs, and IoT platforms.

- Rugged Design: Built for industrial environments with a wide temperature range (-20°C to +55°C) and EMI/EMC immunity, ensuring reliability in harsh conditions.

- Modular Architecture: Configurable I/O options and expandable memory allow scalability for diverse applications, from basic machine control to complex automation systems.

- Real-Time OS: Runs GE’s RTX operating system, providing deterministic performance for mission-critical tasks.

Application Areas and Use Cases

- Industries: Manufacturing, power generation, oil & gas, water treatment.

- Scenarios: Machine control, process automation, remote monitoring, and predictive maintenance.

- Case Study: In a power generation plant, the 04220FL11232A monitors steam turbine parameters (temperature/pressure) via analog inputs, controls auxiliary systems via digital outputs, and communicates with the plant’s SCADA system over Ethernet, improving operational efficiency by 15% through real-time data analysis.

Competitive Comparison

Compared to similar industrial controllers, the 04220FL11232A offers:

- Superior Processing: 1.4 GHz CPU (vs. typical 1.0 GHz in 竞品), enabling faster response times.

- Enhanced Connectivity: Native Ethernet and CANopen support (reducing need for adapters).

- Longevity: Backed by GE’s 10+ year lifecycle support, ensuring compatibility with legacy and modern systems.

- Cost-Efficiency: Balances high performance with competitive pricing, ideal for mid-to-large scale projects.

GE 04220FL11232A

Selection Suggestions

- Compatibility: Verify system requirements (e.g., GE DCS, Mark series turbines) and ensure interface compatibility (Ethernet/RS-485).

- Environment: Assess temperature, vibration, and EMI factors; the 04220FL11232A is suitable for non-hazardous locations (IP20).

- Scalability: Choose based on I/O needs (modular options available) and future expansion plans.

- Budget: Consider refurbished units (1–2 week lead time) for cost savings without compromising performance.

Precautions

- ESD Protection: Use anti-static equipment during installation to avoid damage.

- Firmware Updates: Regularly update via GE’s Asset Manager to address security patches and optimize performance.

- Cooling: Ensure adequate ventilation in high-temperature environments to maintain optimal operation.

- Wiring: Follow GE’s cabling standards (e.g., Deutsch DT connectors) for secure field connections.

- Compliance: Adhere to local regulations (e.g., NEC/CE) for installation in hazardous areas.