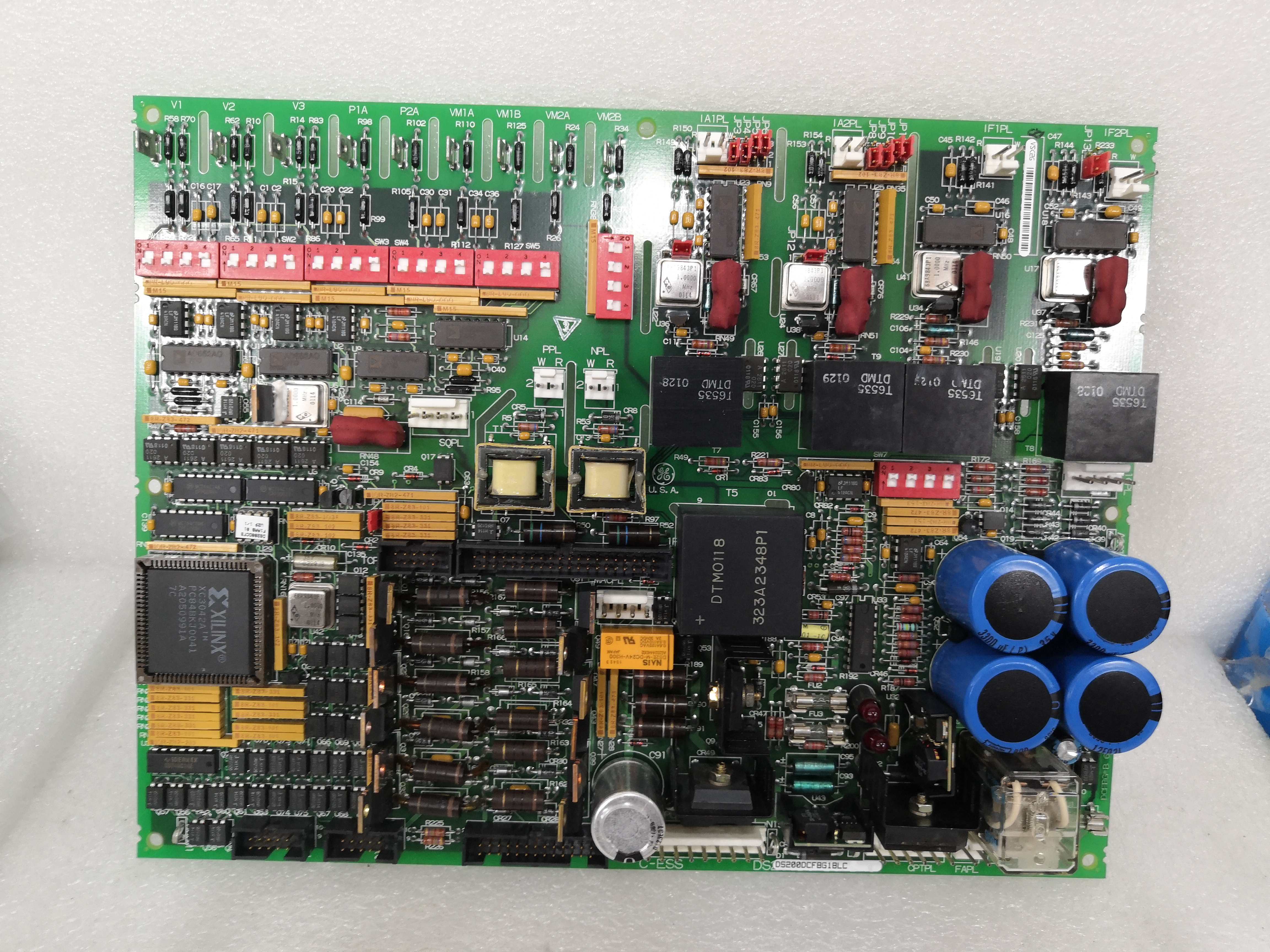

Description

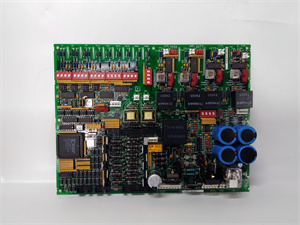

1. Product Description

GE Fanuc DS200DCFBG1BLC is a high-performance automation component designed for distributed control systems (DCS) and industrial IoT (IIoT) applications. As a core module of the IAS4.0 framework, DS200DCFBG1BLC enables flexible, modular, and connected manufacturing by integrating advanced features like distributed control, embedded security, and multi-directional communication. It supports seamless data collection from sensors and devices, facilitating real-time analytics, predictive maintenance, and optimized decision-making. The module reduces hardware dependency, lowers total cost of ownership, and accelerates design cycles through pre-certified applications and libraries. Ideal for industries requiring scalable automation, DS200DCFBG1BLC enhances operational efficiency and supply chain resilience.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Voltage | 200V AC |

| Current | N/A (signal-level processing) |

| Interface Type | Multi-protocol (Ethernet, Modbus) |

| Compatibility | GE DCS systems, industrial IoT platforms |

| Communication | M2M, edge-to-cloud connectivity |

| Security | Embedded cybersecurity protocols |

| Operating Temperature | -40°C to 85°C (industrial grade) |

DS200DCFBG1BLC

3. Advantages and Features

- High Reliability: Built with industrial-grade components and embedded security, ensuring continuous operation in harsh environments.

- Flexible Integration: Reduces 机柜 space and hardware reliance through software-driven architecture, supporting rapid reconfiguration of production lines.

- Real-Time Analytics: Enables seamless data flow to AI/ML platforms, improving predictive maintenance (reducing downtime by up to 30% in automotive applications).

- Shortened Design Cycles: Pre-certified libraries and modular configurations cut development time by 20–25% for machine control systems.

- Scalability: Supports multi-directional communication (M2M, edge-to-cloud) for scalable IIoT deployments.

4. Application Areas and Case Studies

Industries: Manufacturing (automotive, food & beverage), energy, material handling, and industrial automation.

Case Study: A leading automotive manufacturer deployed DS200DCFBG1BLC to transform a legacy production line. The module enabled real-time reconfiguration of vehicle models (e.g., switching between SUVs and sedans on the same line), reducing changeover time by 40% and improving supply chain resilience amid component shortages.

Case Study: A leading automotive manufacturer deployed DS200DCFBG1BLC to transform a legacy production line. The module enabled real-time reconfiguration of vehicle models (e.g., switching between SUVs and sedans on the same line), reducing changeover time by 40% and improving supply chain resilience amid component shortages.

5. Competitor Comparison

Compared to similar DCS modules, DS200DCFBG1BLC offers superior integration with GE’s IAS4.0 ecosystem, combining distributed control, embedded security, and IIoT capabilities in a single unit. Its pre-certified applications and modular design reduce upfront engineering costs by 15–20% compared to generic solutions, while its real-time data processing enhances operational agility.

DS200DCFBG1BLC

6. Selection Recommendations

- Compatibility: Ensure alignment with existing GE DCS systems (e.g., IC698/IC697 PLC series).

- Environment: Verify temperature/humidity ranges match operational conditions (e.g., harsh factory floors vs. controlled environments).

- Scalability: Choose based on required communication protocols (e.g., Ethernet for high-speed data transfer).

- Budget: Balance upfront costs with long-term savings from reduced maintenance and downtime.

7. Precautions

- Installation: Follow ESD (electrostatic discharge) protection protocols during handling.

- Security: Regularly update firmware to address cybersecurity vulnerabilities.

- Maintenance: Schedule annual inspections to clean connectors and verify signal integrity.

- Environment: Avoid exposure to corrosive chemicals or extreme vibrations.