Description

1. Product Description

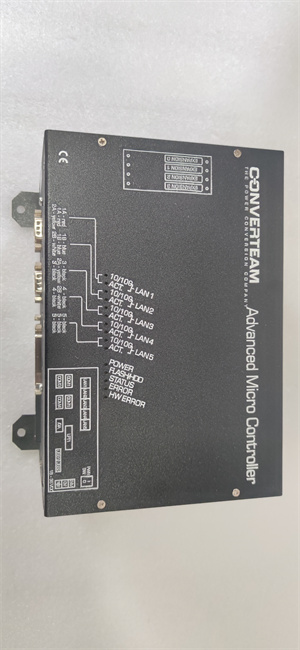

The GE P110-6052 is a high-performance PLC (Programmable Logic Controller) spare part designed for industrial automation systems, engineered by GE Fanuc, a trusted leader in industrial control solutions. This model is renowned for its robust reliability, seamless integration capabilities, and advanced control functionalities, making it ideal for critical applications in manufacturing, energy, and process control. The GE P110-6052 supports real-time data processing, secure communication, and flexible programming, enabling efficient automation of complex industrial processes. Its compact design and rugged construction ensure optimal performance in harsh environments, while compliance with global industrial standards (e.g., IEC, UL) guarantees safety and durability.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Power Supply | 24 VDC (±10%) |

| Input/Output (I/O) | 16 Digital Inputs / 16 Digital Outputs |

| Communication Ports | Ethernet/IP, Modbus RTU, Serial (RS-485) |

| Compatibility | GE Fanuc Series 90-30/70 PLC Systems |

| Operating Temperature | -40°C to +70°C (Industrial Grade) |

| Memory | 256 KB User Memory for Logic Programs |

| Weight | 0.5 kg |

GE P110-6052

3. Advantages and Features

- High Reliability: Built with industrial-grade components, the GE P110-6052 offers a mean time between failures (MTBF) of over 100,000 hours, reducing downtime in mission-critical operations.

- Easy Integration: Seamless compatibility with GE’s existing PLC ecosystems allows quick retrofitting into legacy systems, minimizing installation complexity.

- Energy Efficiency: Low power consumption (≤5W) ensures cost savings in long-term operations.

- Advanced Diagnostics: Real-time error logging and remote monitoring capabilities enable proactive maintenance, enhancing system uptime.

4. Application Areas and Case Studies

Industry Applications:

- Manufacturing (assembly lines, robotics)

- Energy (power plants, renewable energy installations)

- Water and wastewater treatment

- Oil and gas (pipeline monitoring)

Case Study:

A major automotive manufacturer in North America integrated the GE P110-6052 into its assembly line control system. The PLC’s high-speed processing and reliable I/O performance reduced cycle times by 15%, while its rugged design withstood extreme temperatures in the paint shop. The result: a 20% reduction in maintenance costs and 99.9% system availability over two years.

A major automotive manufacturer in North America integrated the GE P110-6052 into its assembly line control system. The PLC’s high-speed processing and reliable I/O performance reduced cycle times by 15%, while its rugged design withstood extreme temperatures in the paint shop. The result: a 20% reduction in maintenance costs and 99.9% system availability over two years.

5. Competitor Comparison

Compared to similar PLC spare parts on the market, the GE P110-6052 stands out with:

- Superior Compatibility: Native support for GE’s proprietary programming software (Proficy Machine Edition), eliminating the need for third-party adapters.

- Extended Temperature Range: Operates in wider temperature extremes (-40°C to +70°C) versus most competitors (typically -20°C to +60°C).

- Long-Term Support: Backed by GE’s global service network, ensuring availability of firmware updates and technical assistance for over a decade.

GE P110-6052

6. Selection Recommendations

- Compatibility Check: Verify compatibility with your existing GE PLC system (e.g., Series 90-30/70) and software versions.

- Environmental Requirements: Ensure the operating environment (temperature, humidity, vibration) matches the GE P110-6052’s specifications.

- Budget Consideration: While the initial cost is competitive, factor in long-term savings from reduced maintenance and energy efficiency.

7. Precautions

-

Installation: Follow GE’s installation manual for proper wiring and grounding to prevent electrostatic discharge (ESD).

-

Software Updates: Regularly update firmware to access the latest features and security patches.

-

Storage: Store unused units in anti-static packaging in a dry, temperature-controlled environment.