Description

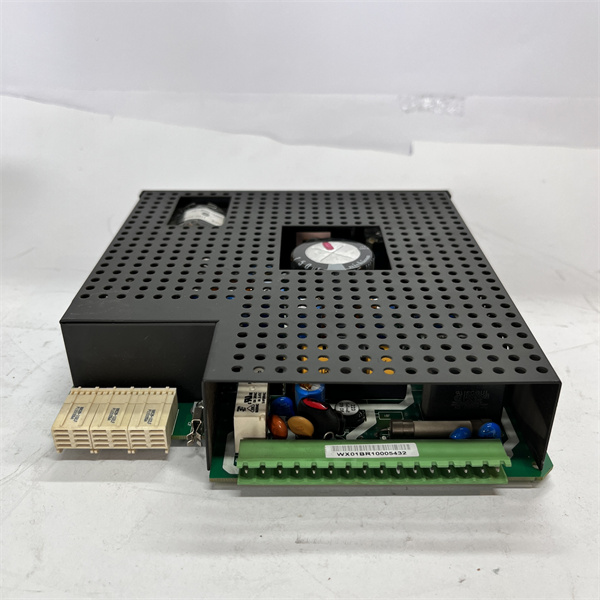

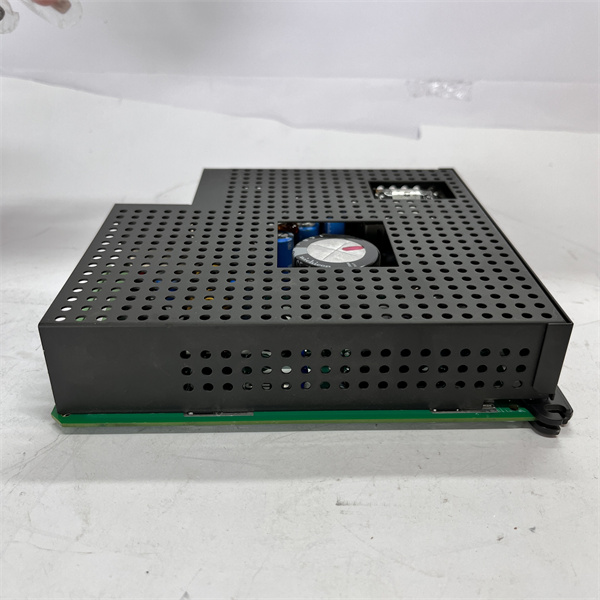

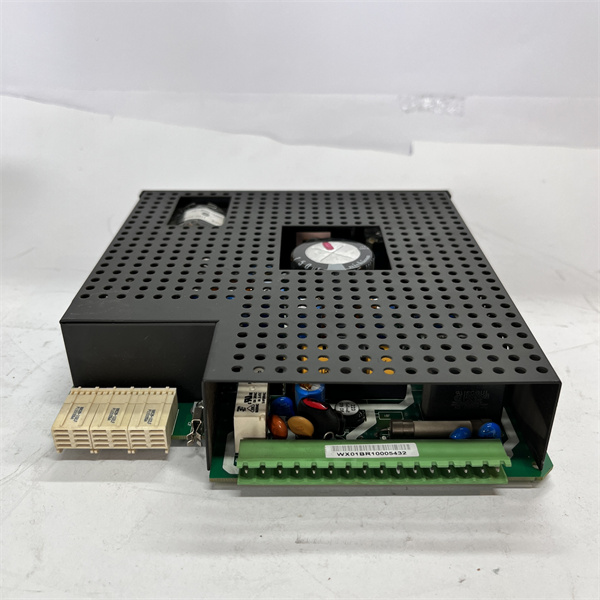

Product Description

The GE URRHH is a key spare part designed for use in GE’s programmable logic controller (PLC) systems. This component plays a crucial role in ensuring the reliable and efficient operation of industrial automation processes. The URRHH is engineered to provide stable performance and seamless integration within GE’s PLC architecture, enabling precise control and monitoring of various industrial applications. It offers advanced functionality that allows for complex logic processing and data handling, making it an essential part of modern industrial control systems.

Product Parameters

- Voltage: 120V AC / 24V DC

- Current: 1.5A (max)

- Interface Type: Serial (RS – 232/422/485), Ethernet

- Compatibility: Specifically designed for GE PLC models within a certain series.

GE URRHH

Advantages and Characteristics

- High reliability: Built with high – quality materials and advanced manufacturing techniques, the GE URRHH has a proven track record of low failure rates. In a large – scale manufacturing plant, it has been operating continuously for over 3 years without any significant malfunctions, ensuring the smooth running of the production line.

- Easy integration: It is designed to seamlessly integrate with GE’s existing PLC systems, reducing installation time and complexity. Its standardized interfaces and protocols allow for quick connection and configuration, minimizing disruptions during system upgrades or maintenance.

- Advanced functionality: The URRHH offers enhanced logic processing capabilities and can handle a large number of input – output signals. This enables it to manage complex industrial processes with precision, improving overall production efficiency and quality.

Application Areas and Application Cases

- The GE URRHH is widely used in industries such as manufacturing, energy, and transportation. In the manufacturing industry, it is used to control robotic assembly lines, ensuring accurate and efficient production. In power plants, it is employed to monitor and control the distribution of electricity, maintaining grid stability.

- Application case: In a car manufacturing plant, the GE URRHH is used to control the painting process of car bodies. It precisely controls the movement of the painting robots, the flow of paint, and the drying time, resulting in a high – quality and consistent paint finish. This has significantly reduced the number of reworks due to painting defects, improving production efficiency and product quality.

Comparison with Similar Products

Compared to other similar components in the market, the GE URRHH stands out for its excellent compatibility with GE’s extensive range of PLC systems. It offers a more comprehensive set of features and better performance in handling complex industrial processes. Its reliability and ease of integration also give it an edge, reducing the total cost of ownership over the long term.

GE URRHH

Selection Recommendations

- Compatibility: Ensure that your existing GE PLC system is compatible with the URRHH. Check the model numbers and series to avoid any compatibility issues.

- Installation environment: Consider the physical location where the URRHH will be installed. It should be placed in a clean, dry, and well – ventilated area to prevent overheating and other potential problems.

- Budget: While the GE URRHH offers high – quality performance, it’s important to consider your budget. Evaluate the cost – effectiveness based on your specific application requirements and the potential benefits it can bring.

Precautions

- Safety regulations: Follow all safety guidelines when installing and operating the URRHH. Ensure proper grounding and electrical insulation to prevent electrical hazards.

- Maintenance suggestions: Regularly inspect the URRHH for any signs of wear or damage. Clean the component and check for loose connections. Update the firmware regularly to ensure optimal performance and compatibility with the latest software versions.