Description

1. Product Description

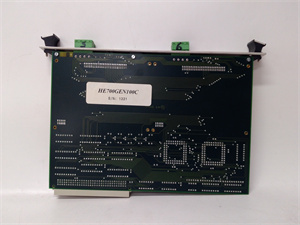

The GE HE700GEN200 is a versatile industrial control module designed for mission-critical applications in VME-based systems, Mark VI/VIe turbine controls, and industrial automation. Available in two variants—contact input module and VME interface module—it bridges the gap between field devices and control systems. The contact input variant offers 24 isolated dry contact inputs with surge protection and noise filtering, ideal for turbine control and machinery monitoring. The interface variant supports Gen-2 NVMe communication and VME 背板 integration, enabling high-speed data transfer in data centers and high-performance computing. With robust reliability features like TMR (Triple Modular Redundancy) support and modular design, the HE700GEN200 ensures seamless integration and long-term operational stability.

2. Product Parameters

| Parameter | Contact Input Variant | VME Interface Variant |

|---|---|---|

| Brand | GE | GE |

| Model | HE700GEN200 | HE700GEN200 |

| Voltage | 24V DC (nominal) | 220V (variant-dependent) |

| Channels | 24 dry contact inputs | N/A (interface-only) |

| Communication | Genius network, VME 背板 | VME 背板,Gen-2 NVMe |

| Redundancy | Single/TMR (Triple Modular Redundancy) | N/A |

| Protection | Surge protection, noise filtering | ESD protection, thermal regulation |

| Mounting | VME rack-mounted (Mark VI compatible) | VME rack-mounted |

| Environment | 0°C–60°C (operation), -40°C–85°C (storage) | Same as contact variant |

| Certifications | CE (select models) | CE (select models) |

HE700GEN200

3. Advantages and Features

- High Reliability: TMR redundancy (contact variant) ensures fault tolerance, with automatic fail-safe mode and diagnostic monitoring (e.g., voltage drop detection <40% nominal).

- Modular Design: Removable terminal blocks (24 terminals, #12 AWG support) simplify maintenance, reducing downtime.

- Versatile Compatibility: Works with GE’s Mark VI/VIe turbines, RX3I PAC systems, and third-party OPC UA devices.

- Noise Immunity: Built-in 4ms hardware filters and surge protection (contact variant) ensure stable operation in harsh environments.

- Flexible Configuration: DIP switches (interface variant) enable custom settings for Gen-2 NVMe devices or Genius network protocols.

4. Application Areas and Case Studies

- Energy Sector: Turbine control systems (Mark VI/VIe) for dry contact signal acquisition (e.g., valve status, sensor inputs).

- Industrial Automation: VME system I/O expansion in manufacturing (CNC machines, production lines).

- Data Centers: High-speed NVMe storage integration (interface variant) for low-latency data processing.

Case Study: A European power plant upgraded its Mark VI turbine control system with GE HE700GEN200 contact modules. The 24-channel TMR configuration reduced downtime by 30% by isolating faulty inputs and triggering fail-safe modes, ensuring continuous operation during component failures.

5. Competitive Comparison

Compared to similar industrial I/O modules, the HE700GEN200 stands out with:

- Native GE Ecosystem Integration: Optimized for GE’s Mark VI/VIe and RX3I systems, reducing compatibility issues.

- Dual Variant Flexibility: Combines contact input (24-channel isolation) and interface (NVMe/VME) capabilities in a single form factor.

- Redundancy Depth: TMR support (contact variant) surpasses standard single/dual redundancy solutions, enhancing safety-critical applications.

HE700GEN200

6. Selection Recommendations

- Voltage Matching: Confirm system voltage (24V DC for contact inputs; 220V for interface variants).

- Redundancy Needs: Choose TMR variant for safety-critical systems (e.g., turbines, aerospace).

- Environment: Ensure temperature range (0°C–60°C operation) matches industrial settings.

- Compatibility: Verify VME 背板 or Genius network compatibility with existing GE or third-party systems.

7. Precautions

- Installation: Align modules carefully in VME racks to avoid connector damage. Use ESD-protective gear during handling.

- Maintenance: Regularly inspect terminal block connections; replace corroded terminals. Monitor diagnostic alerts for voltage irregularities.

- Redundancy Setup: In TMR systems, ensure all three modules (JR1, JS1, JT1 connectors) are synchronized for consistent voting.

- Voltage Stability: Use regulated power supplies (±10% tolerance) to prevent performance degradation.