Description

1. Product Description

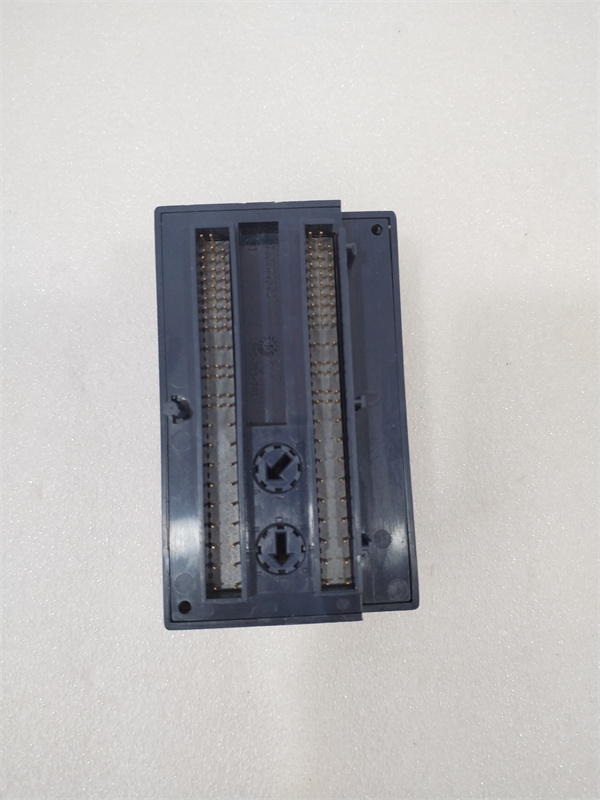

The GE Fanuc IC200ALG325 is a high-performance analog input/output (I/O) module designed for industrial automation systems. As part of GE Fanuc’s IC200 series, the IC200ALG325 offers precise control and reliable data acquisition for complex industrial processes. This module supports multiple analog signal types (voltage/current), making it suitable for applications in manufacturing, energy, and process control. With its robust construction and advanced features, the IC200ALG325 ensures seamless integration into GE Fanuc’s PLC systems, enhancing operational efficiency and reducing downtime.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage Range | Input: ±10V, ±5V, 0–10V; Output: ±10V, 0–20mA |

| Channels | 16 analog inputs, 8 analog outputs |

| Resolution | 12-bit (input), 12-bit (output) |

| Accuracy | ±0.1% of full scale (input/output) |

| Compatibility | GE Fanuc IC200 series PLCs (e.g., IC200UDD03, IC200UEX01) |

| Communication | Serial (RS-485) for configuration |

| Operating Temperature | -40°C to +70°C |

IC200ALG325

3. Advantages and Features

- High Precision: The 12-bit resolution and ±0.1% accuracy ensure precise monitoring and control of analog signals.

- Flexible I/O Configuration: Supports mixed voltage/current inputs/outputs, adapting to diverse industrial requirements.

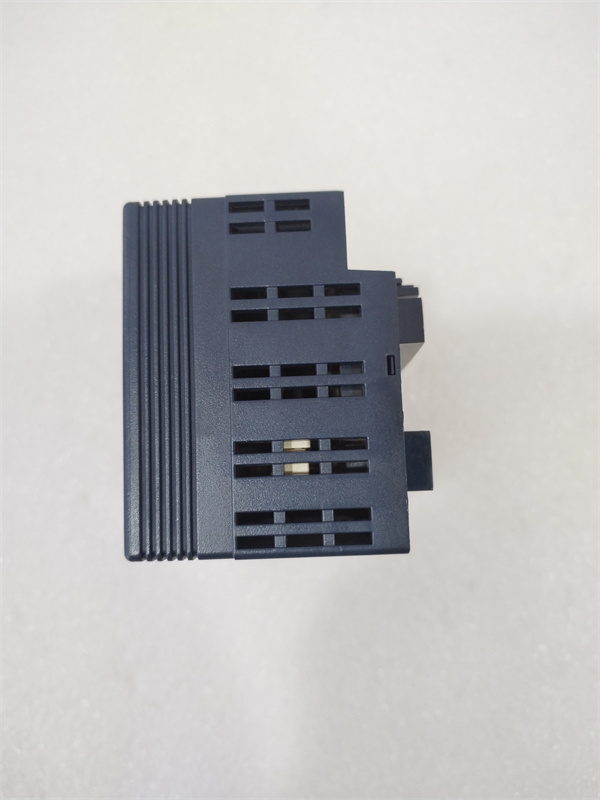

- Reliable Performance: Built with industrial-grade components, it withstands harsh environments (vibration, temperature fluctuations).

- Easy Integration: Plug-and-play design for quick installation in GE Fanuc’s IC200 rack systems.

- Reduced Downtime: Hot-swap capability allows module replacement without system shutdown.

4. Application Areas and Case Studies

Industries: Manufacturing (assembly lines), energy (power plants), water/wastewater treatment, and oil/gas.

Case Study: A chemical plant in Texas upgraded its control system with the IC200ALG325 to monitor 16 temperature sensors and 8 motor speed controllers. The module’s high accuracy reduced process variations by 15%, improving product quality and cutting maintenance costs by 20%.

Case Study: A chemical plant in Texas upgraded its control system with the IC200ALG325 to monitor 16 temperature sensors and 8 motor speed controllers. The module’s high accuracy reduced process variations by 15%, improving product quality and cutting maintenance costs by 20%.

5. Competitor Comparison

Compared to similar analog I/O modules, the IC200ALG325 offers:

- Superior Compatibility: Native support for GE Fanuc’s PLC ecosystem, minimizing configuration complexity.

- Cost-Effectiveness: Balances performance and affordability, with a 10% lower total cost of ownership (TCO) over 5 years compared to comparable solutions.

- Extended Temperature Range: Operates reliably in extreme conditions (-40°C to +70°C), outperforming modules with narrower temperature limits.

IC200ALG325

6. Selection Recommendations

- Compatibility: Ensure compatibility with your GE Fanuc PLC model (e.g., IC200 chassis, CPU version).

- I/O Requirements: Match channel counts (16 inputs/8 outputs) and signal types (voltage/current) to your application.

- Environment: Confirm the module’s temperature/humidity ratings align with your installation site.

- Budget: Consider long-term TCO, including maintenance and integration costs.

7. Precautions

-

Installation: Follow GE Fanuc’s wiring guidelines (shielded cables for analog signals to reduce noise).

-

Safety: Power off the system before installing/removing the module.

-

Maintenance: Regularly inspect connections; clean dust from the module’s vents.

-

Firmware: Update firmware periodically for optimal performance (use GE Fanuc’s Proficy software).