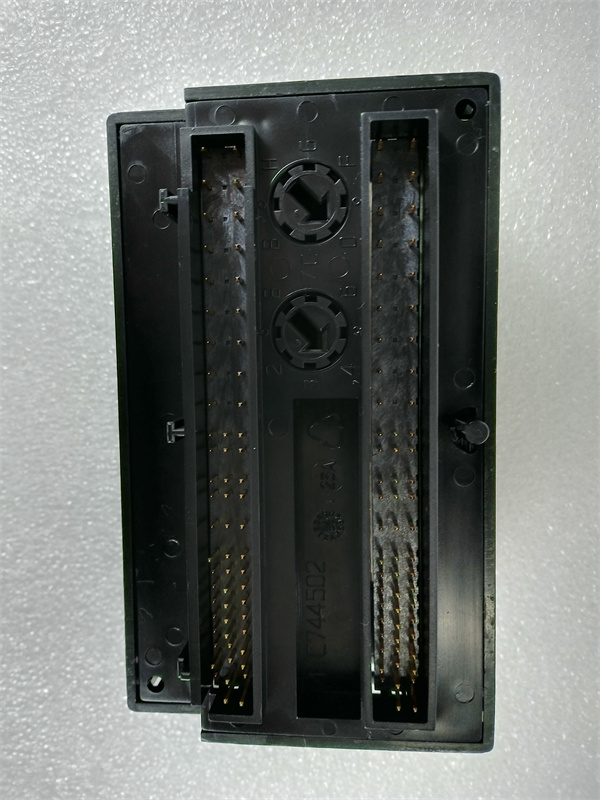

Description

IC200ALG630

The IC200ALG630 is a crucial programmable logic controller (PLC) spare part. It is designed to meet the specific requirements of various industrial control applications.

1. Product Description

The IC200ALG630 is an advanced analog input module in the [brand] PLC family. It plays a vital role in converting analog signals from sensors and other devices into digital signals that the PLC can process. This module is capable of handling multiple analog input channels simultaneously, allowing for precise monitoring and control of various physical parameters such as temperature, pressure, and voltage. With its high – resolution analog – to – digital conversion, the IC200ALG630 ensures accurate measurement and control, making it an essential component in industrial automation systems. The IC200ALG630 is known for its reliability and stability, providing consistent performance in harsh industrial environments.

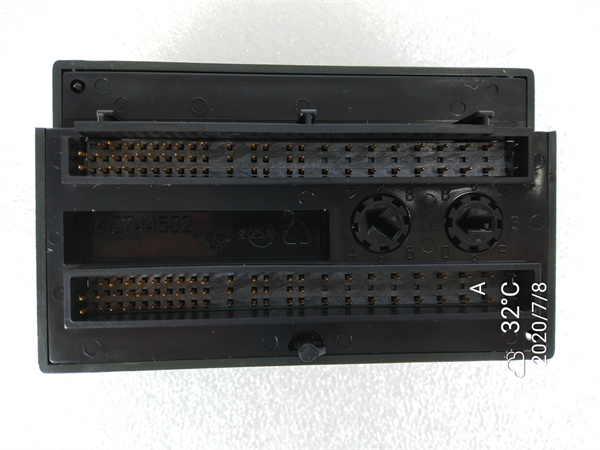

2. Product Parameters

- Input Voltage Range: 0 – 10V DC, 0 – 20mA

- Resolution: 12 – bit

- Number of Channels: 8

- Interface Type: Proprietary bus interface for [brand] PLCs

- Compatibility: Compatible with [brand] IC200 series PLCs

IC200ALG630

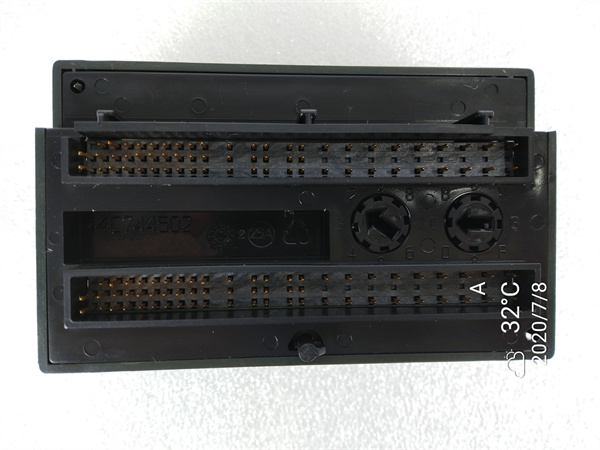

3. Advantages and Features

- High – accuracy measurement: The 12 – bit resolution allows for precise measurement of analog signals, with an accuracy of up to ±0.1% of the full – scale range. This ensures that the control system can respond accurately to changes in the monitored parameters. For example, in a chemical process control application, the IC200ALG630 can accurately measure the temperature and pressure of the reaction vessel, enabling precise control of the process to ensure product quality.

- Multiple input channels: The module has 8 input channels, which reduces the need for additional modules and simplifies the system architecture. This leads to cost savings and easier maintenance.

- Wide input range: The ability to handle both voltage and current inputs in a wide range makes the IC200ALG630 suitable for a variety of sensors and applications.

4. Application Areas and Application Cases

- The IC200ALG630 is widely used in the manufacturing industry for process control, such as in the production of electronics, where it is used to monitor and control the temperature and humidity in clean rooms. In a semiconductor manufacturing plant, the IC200ALG630 was used to monitor the temperature of the wafer processing equipment. By accurately measuring the temperature and providing feedback to the control system, the module helped to improve the yield of the production process by reducing the number of defective wafers.

- It is also used in the energy industry for monitoring and controlling power generation and distribution systems. For example, in a wind farm, the IC200ALG630 is used to measure the wind speed and direction, as well as the voltage and current of the generator, to optimize the power output.

5. Competitor Comparison

Compared to other similar analog input modules, the IC200ALG630 offers a higher resolution and a wider input range, providing more accurate measurement and greater flexibility in different applications. Its compatibility with the [brand] IC200 series PLCs also ensures seamless integration into existing systems, reducing the need for additional interface components.

IC200ALG630

6. Selection Recommendations

- When selecting the IC200ALG630, consider the number of analog input channels required for your application. Make sure that the input voltage and current ranges of the module match the output signals of your sensors. Also, check the compatibility with your existing PLC system to ensure proper integration.

- If your application requires high – accuracy measurement and a wide input range, the IC200ALG630 is an ideal choice. Consider your budget, but keep in mind that the high – performance features of this module can provide long – term benefits in terms of system reliability and performance.

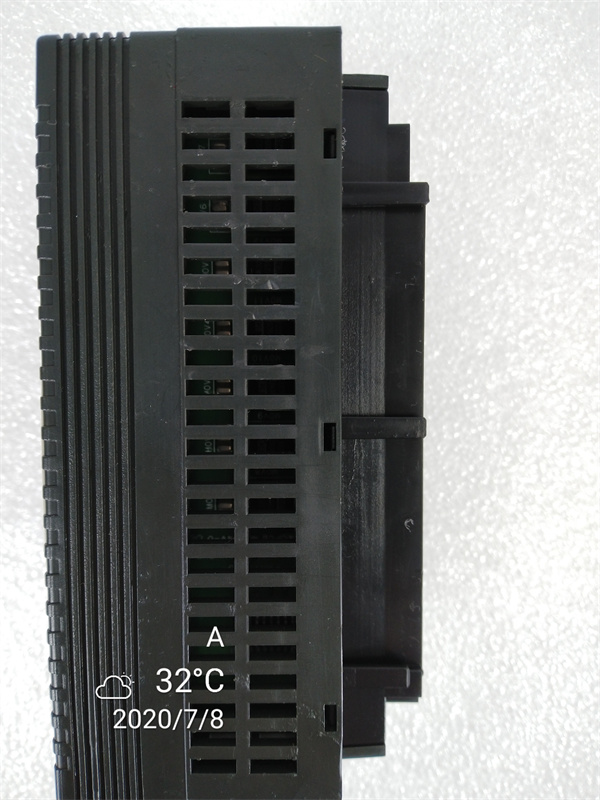

7. Precautions

- When installing the IC200ALG630, follow the installation instructions carefully to ensure proper connection and grounding. Avoid exposing the module to high temperatures, humidity, and electromagnetic interference.

- Regularly check the input signals and the module’s status to ensure accurate measurement. Calibrate the module periodically to maintain its accuracy.