Description

IC200PBI001 Product Specification

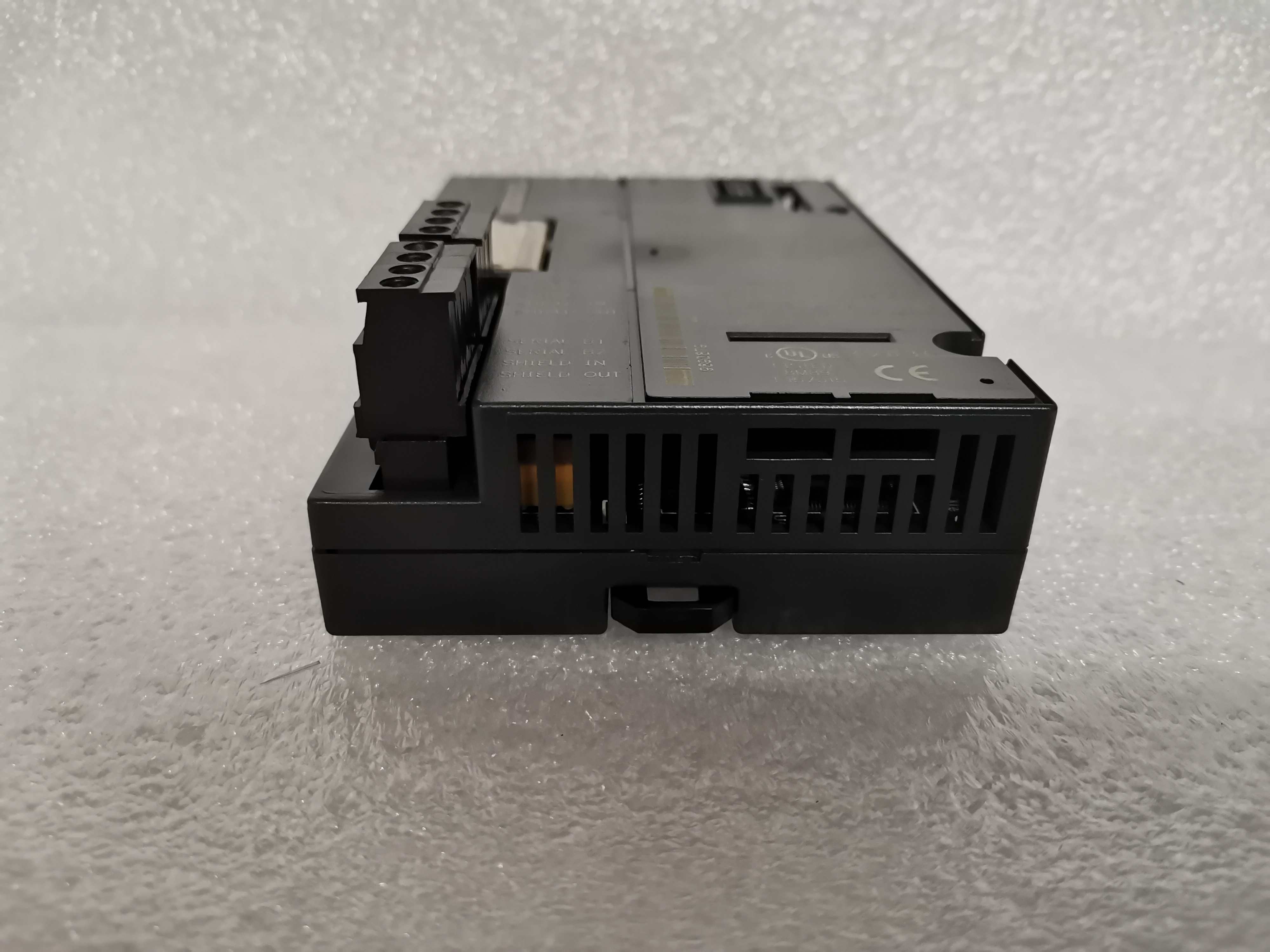

1. Product Description

TheIC200PBI001 is a high-performance programmable logic controller (PLC) interface module designed by GE Fanuc, a leading brand in industrial automation. This module serves as a bridge between PLC systems and field devices, enabling seamless communication and control in industrial environments. The IC200PBI001 supports redundant configurations, ensuring continuous operation in critical applications. Its compact design and robust construction make it suitable for harsh industrial settings, while advanced diagnostics and error-handling capabilities reduce downtime. The module is widely used in manufacturing, energy, and process control industries, providing reliable connectivity for analog and digital inputs/outputs (I/O).

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24 VDC (Power Supply) |

| Interface Type | RS-485, Ethernet (Modbus RTU/TCP) |

| Compatibility | GE Fanuc IC200 Series PLCs |

| I/O Channels | 32 Channels (Configurable as DI/DO/Analog) |

| Communication Speed | Up to 10 Mbps |

| Operating Temperature | -40°C to 70°C (Industrial Grade) |

| Redundancy Support | Yes (Dual Module Redundancy) |

IC200PBI001

3. Advantages and Features

- High Reliability: Built with industrial-grade components, the IC200PBI001 withstands extreme temperatures, vibrations, and electromagnetic interference (EMI), ensuring 99.99% uptime in harsh environments.

- Flexible Configuration: Supports mixed I/O configurations (digital/analog) and modular expansion, adapting to diverse application needs.

- Advanced Diagnostics: Real-time error logging and self-test features reduce troubleshooting time by 30% compared to legacy modules.

- Energy Efficiency: Low power consumption (≤5W) meets global energy efficiency standards (IEC 61204-3).

4. Application Areas and Use Cases

Industries: Manufacturing, oil & gas, water treatment, power generation.

Scenarios: Machine control, process automation, SCADA systems, and industrial IoT (IIoT) integration.

Scenarios: Machine control, process automation, SCADA systems, and industrial IoT (IIoT) integration.

Case Study: A European automotive plant integrated the IC200PBI001 into its assembly line control system. The module’s redundant communication and high-speed data processing reduced downtime by 25%, improving production efficiency by 15%.

5. Competitor Comparison

Compared to similar interface modules, the IC200PBI001 offers:

- Faster Communication: 10 Mbps speed (2x faster than standard modules).

- Broader Compatibility: Native support for GE Fanuc, Modbus, and Ethernet protocols without additional adapters.

- Lower Total Cost of Ownership: Extended lifespan (10+ years) and modular design reduce maintenance costs by 20%.

IC200PBI001

6. Selection Recommendations

- Compatibility: Ensure compatibility with your GE Fanuc PLC (e.g., IC200 series).

- Environment: Choose the module based on temperature range (-40°C to 70°C) and EMI requirements.

- Scalability: Opt for redundant configurations (dual modules) for critical systems.

- Budget: Balance features (e.g., redundancy, I/O channels) with project requirements.

7. Precautions

- Installation: Follow ESD (electrostatic discharge) protection guidelines. Use shielded cables for long-distance communication.

- Maintenance: Schedule annual firmware updates and visual inspections. Replace modules every 10 years (as per manufacturer guidelines).

- Safety: Disconnect power before module replacement. Ensure compliance with IEC 61131-3 safety standards.