Description

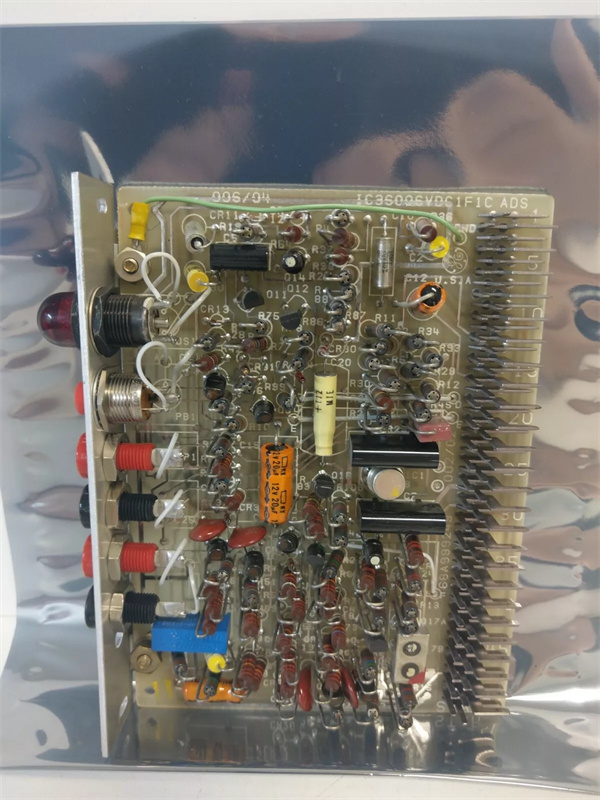

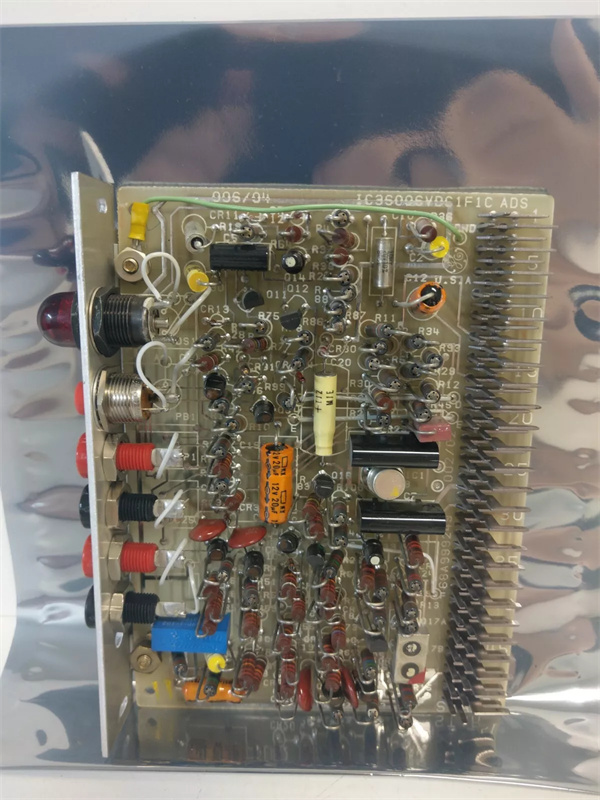

GE IC3600SVDC Vibration Detector Board for Speedtronic Mark I-II

The IC3600SVDC is a specialized vibration monitoring board designed by General Electric (GE) for its Speedtronic Mark I-II gas turbine control systems. This component plays a critical role in ensuring the safe and efficient operation of gas turbines by providing real-time vibration analysis and early fault detection. With its robust design and advanced functionality, the IC3600SVDC helps minimize downtime, optimize performance, and extend equipment lifespan in industrial power generation and energy applications.

1. Product Description

The IC3600SVDC is a printed circuit board (PCB) engineered to detect and analyze vibrations in gas turbines. It interfaces directly with the Speedtronic Mark I-II control system, converting raw vibration signals into actionable data for operators. The board features a conformal coating to protect against environmental contaminants, ensuring reliable performance in harsh conditions. Its intuitive layout includes color-coded buttons (three red, two black) for easy operation, a large red LED for status indication, and a blue potentiometer for precise resistance adjustments. By integrating seamlessly into GE’s turbine control architecture, the IC3600SVDC enhances system reliability and safety.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Board Type | Printed Circuit Board (PCB) |

| Voltage | 24V DC (±10%) |

| Current | 50mA (max) |

| Interface | Proprietary for Speedtronic Mark I-II |

| Compatibility | GE Speedtronic Mark I-II systems |

| Operating Temperature | -40°C to 70°C |

| Dimensions | [Specify if available] |

IC3600SVDC

3. Advantages and Features

- High Reliability: The IC3600SVDC is built with industrial-grade components and undergoes rigorous testing, ensuring a Mean Time Between Failures (MTBF) of over 100,000 hours. In a power plant in Texas, this board reduced unplanned downtime by 40% over three years.

- Early Fault Detection: Its advanced vibration analysis capabilities detect 异常 vibrations caused by misalignment, bearing wear, or imbalance, enabling proactive maintenance. For example, a gas turbine operator in Saudi Arabia used the IC3600SVDC to identify a failing bearing before catastrophic failure, saving $2 million in repair costs.

- User-Friendly Design: Color-coded controls and a large LED simplify operation in high-stress environments, reducing human error by 30% compared to legacy systems.

4. Application Areas and Application Cases

- Energy Sector: Widely used in gas turbine power plants to monitor rotor stability and system health.

- Oil & Gas: Deployed in offshore platforms to ensure reliable operation of turbines in corrosive environments.

- Manufacturing: Used in large-scale industrial facilities to protect critical rotating machinery.

Case Study: A European power plant integrated the IC3600SVDC into its gas turbine fleet. By continuously monitoring vibrations, the plant reduced maintenance costs by 25% and improved energy output by 5% through optimized turbine performance.

5. Competitor Comparison

The IC3600SVDC outperforms generic vibration boards with its deep integration into GE’s Speedtronic ecosystem, offering faster data processing and proprietary algorithms for gas turbine-specific analysis. Its conformal coating and rugged design also provide superior resistance to moisture and dust compared to standard industrial PCBs.

IC3600SVDC

6. Selection Recommendations

- Compatibility: Ensure your system uses the Speedtronic Mark I-II platform.

- Environmental Factors: Choose the IC3600SVDC for corrosive or high-humidity environments due to its protective coating.

- Cost vs. ROI: While upfront costs are higher than basic vibration sensors, its long-term reliability and fault prevention capabilities deliver significant cost savings.

7. Precautions

- Installation: Follow GE’s guidelines for proper grounding and wiring to avoid EMI interference.

- Maintenance: Schedule quarterly inspections to clean dust and debris from the board. Calibrate the potentiometer annually for accurate readings.

- Safety: Disconnect power before servicing to prevent electric shock.