Description

IC693ACC302 Product Specification

1. Product Overview

GE Fanuc IC693ACC302 is a high-performance communication module designed for GE Fanuc PACSystems RX3i PLC systems. It serves as a bridge between industrial automation networks and control systems, enabling seamless data exchange across multiple protocols. The IC693ACC302 supports Ethernet/IP, Modbus TCP, and other industrial communication standards, making it ideal for integrating PLCs with HMIs, SCADA systems, and third-party devices. With robust security features and real-time performance, the IC693ACC302 ensures reliable connectivity in critical applications.

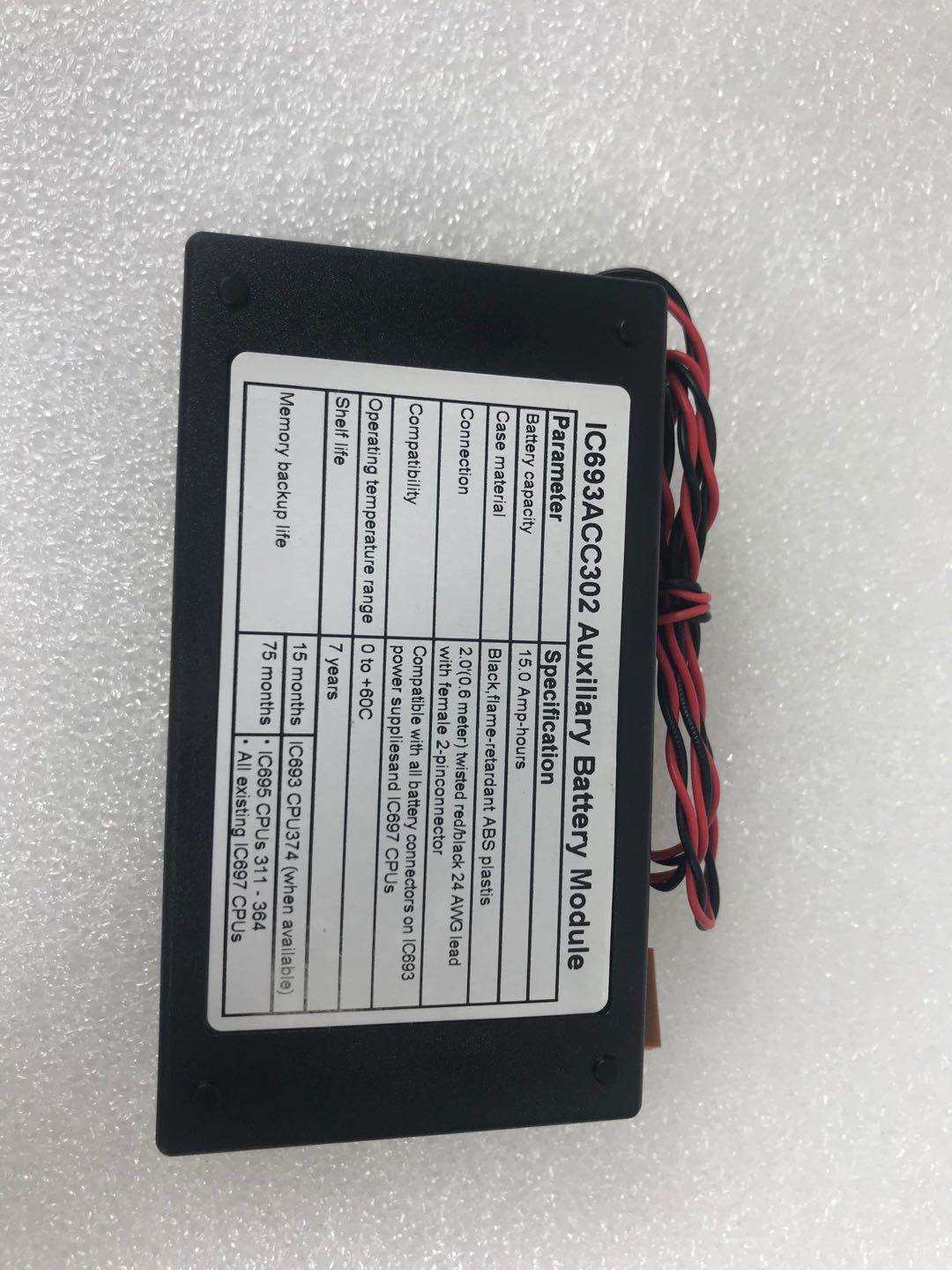

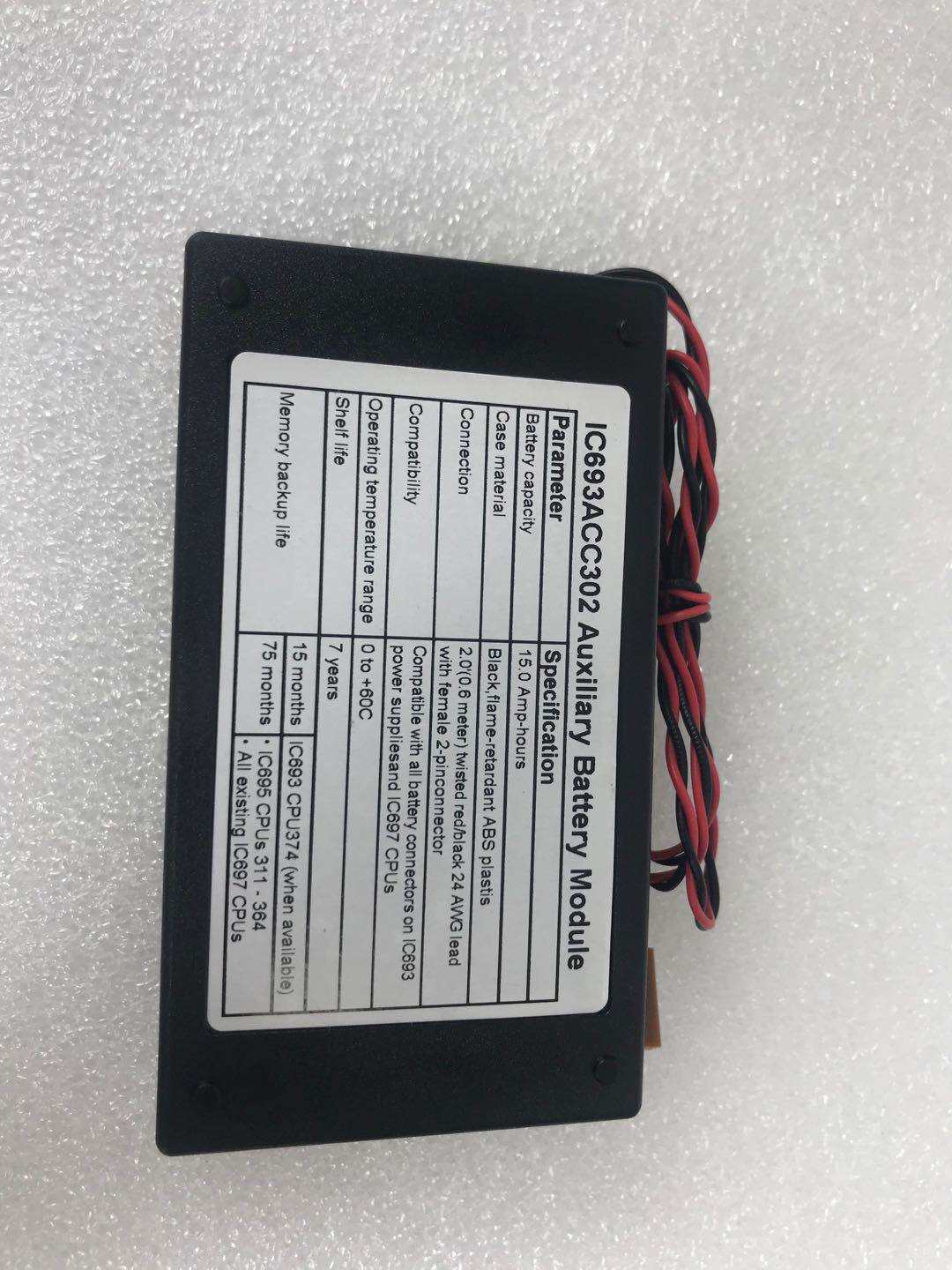

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Brand | GE Fanuc |

| Model | IC693ACC302 |

| Series | PACSystems RX3i |

| Voltage | 24V DC (±10%) |

| Current Consumption | 80 mA (max) |

| Communication Protocols | Ethernet/IP, Modbus TCP, UDP, TCP/IP |

| Interfaces | 1x RJ45 (10/100BASE-TX) |

| Compatibility | RX3i controllers (e.g., IC693CPU364) |

| Data Rate | Up to 100 Mbps |

| Operating Temperature | -40°C to +60°C |

IC693ACC302

3. Advantages and Features

- Multi-Protocol Support: The IC693ACC302 supports Ethernet/IP and Modbus TCP, reducing the need for additional gateways in mixed-network environments.

- Real-Time Performance: Achieves sub-millisecond latency for time-sensitive applications, ensuring rapid response to process changes.

- Redundancy Ready: Compatible with GE Fanuc’s dual-network architecture, enhancing system reliability (e.g., 99.999% uptime in redundant setups).

- Easy Configuration: Integrated Web server allows remote setup and diagnostics via a browser, minimizing commissioning time.

4. Application Areas and Cases

Industry Applications:

- Manufacturing (assembly lines, robotics)

- Energy (power plants, renewable energy grids)

- Water/Wastewater treatment

- Automotive production

Case Study:

A manufacturing plant integrated the IC693ACC302 to connect GE Fanuc PLCs with robotic arms via Ethernet/IP. The module enabled real-time synchronization of motion control commands, reducing cycle time by 15% and improving overall equipment effectiveness (OEE).

A manufacturing plant integrated the IC693ACC302 to connect GE Fanuc PLCs with robotic arms via Ethernet/IP. The module enabled real-time synchronization of motion control commands, reducing cycle time by 15% and improving overall equipment effectiveness (OEE).

5. Competitor Comparison

Compared to similar communication modules, the IC693ACC302 stands out with:

- Broader Protocol Support: Native support for both Ethernet/IP and Modbus TCP (vs. limited protocols in some alternatives).

- Compact Design: 50% smaller than legacy modules while offering higher port density.

- Cost-Effectiveness: Lower total cost of ownership due to simplified configuration and reduced maintenance needs.

IC693ACC302

6. Selection Recommendations

- Compatibility: Ensure compatibility with your GE Fanuc RX3i controller (e.g., IC693CPU364/374).

- Protocol Requirements: Choose the IC693ACC302 if your system requires both Ethernet/IP and Modbus TCP connectivity.

- Environment: Verify temperature and humidity ranges match your installation site (e.g., harsh industrial environments require -40°C to +60°C tolerance).

7. Precautions

- Installation: Avoid electrostatic discharge (ESD) by using anti-static equipment.

- Network Security: Enable built-in firewall features to protect against unauthorized access.

- Firmware Updates: Regularly update firmware via GE Fanuc’s Proficy software for optimal performance.

Note: The IC693ACC302A is an updated variant of the IC693ACC302 with minor firmware improvements. Ensure you select the correct revision for your system.