Description

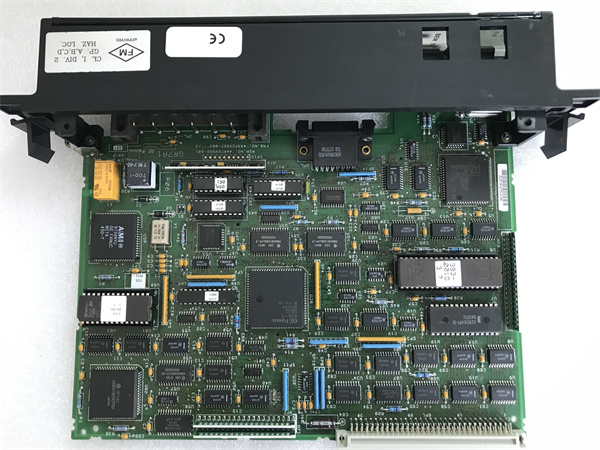

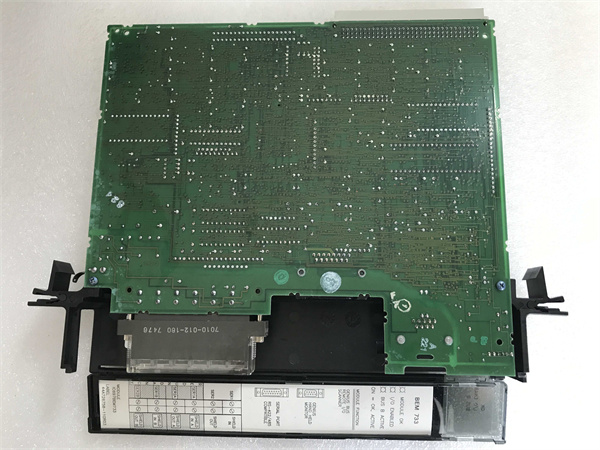

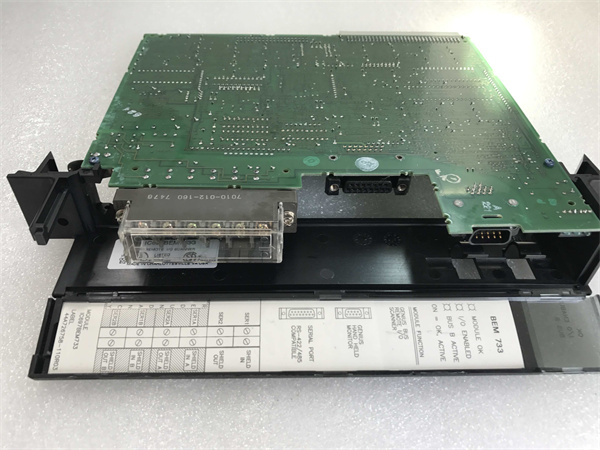

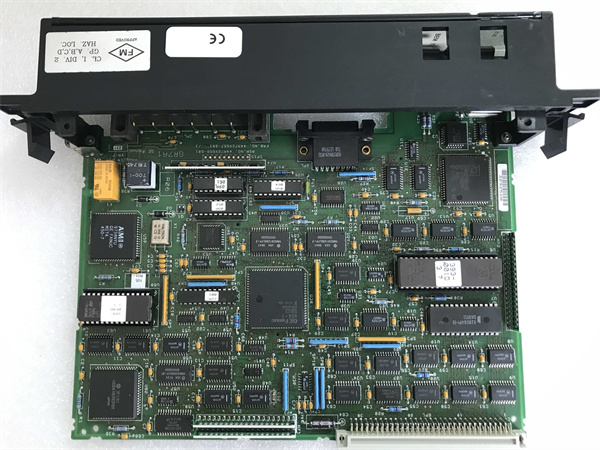

GE Fanuc IC697BEM733 Backplane Expansion Module

GE Fanuc IC697BEM733 is an advanced backplane expansion module designed for GE’s Series 90-70 PLC platform, offering enhanced scalability and reliability for industrial automation systems. This module supports high-speed data transfer via the Genius Bus protocol, enabling seamless integration of up to 4 additional I/O racks per controller. With redundant hot-swap capabilities and rugged construction, the IC697BEM733 ensures continuous operation in harsh environments while simplifying system expansion.

Product Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 24 VDC ±10% |

| Power Consumption | 4 W |

| Interface Type | GE Genius Bus (supports up to 16 modules per backplane) |

| Compatibility | GE Series 90-70 PLCs, Proficy Machine Edition software |

| Rack Expansion | Supports up to 4 additional I/O racks per controller |

| Redundancy Support | Dual-controller hot-swap capability |

| Operating Temperature | -40°C to 70°C |

| Dimensions | 150 mm x 100 mm x 60 mm |

| Weight | 0.45 kg |

| Isolation | 2,500 VDC between modules and ground |

IC697BEM733

Advantages and Features

-

Enhanced Scalability:

- Expands system capacity to 256 I/O channels per controller, ideal for large-scale applications requiring extensive monitoring and control.

- Supports mixed I/O configurations (analog, digital, and specialty modules) for versatile automation solutions.

-

Advanced Redundancy:

- Dual-controller redundancy with hot-swap functionality ensures zero downtime during module replacement, reducing maintenance costs by up to 30%.

-

Rapid Data Transfer:

- Genius Bus technology enables real-time communication with sub-millisecond latency, critical for fast-response processes.

-

Robust Design:

- Withstands extreme temperatures (-40°C to 70°C) and vibration, making it suitable for oil refineries, mining, and other harsh environments.

Application Areas and Use Cases

- Energy:

Expands PLC systems in wind farms to manage turbine sensors and grid integration across distributed racks. - Automotive:

Connects robotic welding stations and conveyor systems in assembly plants for centralized control. - Water Treatment:

Integrates multiple I/O racks to monitor pumps, valves, and chemical dosing systems in large-scale facilities.

Case Study:

A North American power plant deployed IC697BEM733 modules to expand its boiler control system. By adding 3 racks with 96 I/O channels, the plant reduced downtime by 25% during turbine startups and improved energy efficiency by 18% through centralized data analysis.

IC697BEM733

Competitor Comparison

The IC697BEM733 distinguishes itself through:

- Higher Rack Density: Supports 4 racks compared to most alternatives’ 2-3 racks.

- Extended Temperature Range: Operates in -40°C to 70°C, exceeding standard modules’ 0°C to 50°C limits.

- Dual-Controller Redundancy: Offers seamless failover, a feature often limited to premium-tier solutions.

Selection Recommendations

- System Complexity: Choose the IC697BEM733 for systems requiring over 64 I/O channels; consider simpler modules (e.g., IC697BEM701) for smaller setups.

- Redundancy Needs: Opt for this module if your application demands fault tolerance, as it eliminates single points of failure.

- Budget: While slightly more expensive than basic expansion modules, its redundancy features justify the investment for mission-critical operations.

Precautions

-

Installation:

- Ensure proper grounding and cable routing to prevent EMI interference.

- Use only GE-approved Genius Bus cables for reliable communication.

-

Maintenance:

- Clean ventilation slots quarterly to maintain optimal cooling.

- Test redundancy failover every 6 months to confirm functionality.

-

Safety:

- Power off the system before module replacement to avoid ESD damage.

- Secure all connections to prevent dislodging during equipment vibration.