Description

1. Product Description

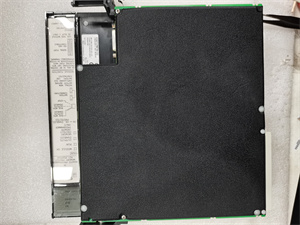

The IC697CPM790-GD is a high-performance programmable logic controller (PLC) module designed by GE Fanuc, a leading brand in industrial automation. This module is part of the GE Fanuc Versamax™ series, renowned for its versatility and reliability in critical industrial applications. The IC697CPM790-GD serves as a central processing unit (CPU) module, enabling precise control, data processing, and communication in automation systems. Its core functions include real-time data handling, modular scalability, and support for multiple communication protocols (e.g., Ethernet/IP, Modbus). Ideal for industries such as manufacturing, energy, and water treatment, the IC697CPM790-GD offers seamless integration with existing systems, reducing downtime and enhancing operational efficiency.

2. Product Specifications

| Parameter | Details |

|---|---|

| Model | IC697CPM790-GD |

| Brand | GE Fanuc |

| Series | Versamax™ |

| Voltage | 24 VDC (±10%) |

| Memory | 512 KB user program memory, 256 KB data memory |

| Communication Interfaces | Ethernet/IP, Modbus RTU, Serial (RS-232/RS-485) |

| I/O Compatibility | Supports GE Fanuc Versamax I/O modules (e.g., digital, analog, specialty) |

| Operating Temperature | -40°C to +70°C (wide temperature range) |

| Dimensions | 101.6 mm (W) × 127 mm (H) × 76.2 mm (D) |

IC697CPM790-GD

3. Advantages and Features

- High Reliability: Built with industrial-grade components, the IC697CPM790-GD offers a mean time between failures (MTBF) of over 100,000 hours, ensuring continuous operation in harsh environments.

- Modular Design: Seamlessly integrates with GE Fanuc’s Versamax I/O modules, allowing scalable configurations for small to large systems.

- Energy Efficiency: Low power consumption (≤5W) reduces operational costs.

- Advanced Diagnostics: Onboard LED indicators and remote monitoring via Proficy® software enable predictive maintenance.

- Flexible Communication: Supports multi-protocol networks, making it suitable for hybrid automation setups.

4. Application Areas and Use Cases

Industries: Manufacturing (assembly lines), energy (power plants), water/wastewater treatment, and automotive.

Use Case: A leading automotive manufacturer deployed the IC697CPM790-GD in its assembly line to control robotic welding stations. The module’s real-time data processing and Ethernet/IP compatibility reduced cycle times by 15% and improved error detection accuracy by 20%.

Use Case: A leading automotive manufacturer deployed the IC697CPM790-GD in its assembly line to control robotic welding stations. The module’s real-time data processing and Ethernet/IP compatibility reduced cycle times by 15% and improved error detection accuracy by 20%.

5. Competitive Comparison

Compared to similar CPU modules in the market, the IC697CPM790-GD stands out with:

- Superior Temperature Range: Operates in extreme conditions (-40°C to +70°C), versus typical ranges of -20°C to +60°C.

- Faster Data Processing: 0.15 ms/kB scan time (vs. 0.2–0.3 ms/kB for 竞品).

- Integrated Security: Built-in password protection and firmware encryption for enhanced cybersecurity.

IC697CPM790-GD

6. Selection Recommendations

- Compatibility: Ensure compatibility with existing GE Fanuc Versamax I/O modules and software (e.g., Proficy Machine Edition).

- Environment: Consider temperature, humidity, and vibration levels; the IC697CPM790-GD is ideal for harsh environments.

- Scalability: Choose based on I/O 点数 and memory requirements (e.g., 512 KB program memory suits medium to complex projects).

- Budget: Balance features with cost; the module offers a high ROI through long-term reliability and energy savings.

7. Precautions

- Installation: Follow ESD (electrostatic discharge) protocols; use anti-static wrist straps.

- Power Supply: Ensure stable 24 VDC input to prevent voltage spikes.

- Firmware Updates: Regularly update firmware via GE Fanuc’s official tools to access new features and security patches.

- Maintenance: Clean dust and debris from vents quarterly; inspect wiring connections annually.