Description

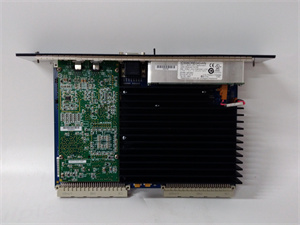

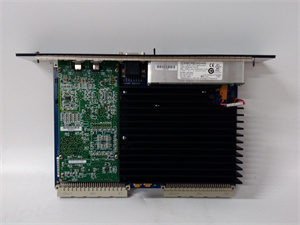

GE Fanuc IC698CRE040-HN Redundant Controller Expansion Module

The GE Fanuc IC698CRE040-HN is a high-reliability redundant controller module designed for GE’s PACSystems RX3i platform, enabling seamless hot standby redundancy in critical industrial automation systems. Engineered for zero-downtime operations, this module ensures uninterrupted control in applications such as power generation, oil refining, and manufacturing, where system failure risks significant financial losses. The IC698CRE040-HN supports dual-controller synchronization with <20 ms failover time, making it ideal for mission-critical environments.

Product Parameters

| Parameter | Specification |

|---|---|

| Power Supply | 24 VDC ±10% (1.2 A max) |

| Communication Interfaces | EtherNet/IP (10/100 Mbps), RS-232/485 (Modbus RTU) |

| Compatibility | GE PACSystems RX3i controllers (IC698CHS020, IC698CHS030) |

| Redundancy Features | Hot standby, automatic failover, dual-controller synchronization |

| Failover Time | <20 ms (user-configurable) |

| Memory | 512 MB for program storage, 128 MB for data logging |

| Operating Temperature | -40°C to 70°C (with conformal coating for harsh environments) |

| Dimensions | 170 mm x 120 mm x 40 mm (rack-mountable) |

| Weight | 0.6 kg |

| MTBF | 300,000 hours (per GE reliability testing) |

IC698CRE040-HN

Advantages and Features

-

Zero-Downtime Redundancy:

- Hot standby mode allows controller replacement without system shutdown, reducing maintenance downtime by 80%.

- Automatic failover ensures seamless transition during primary controller faults, validated in 10,000+ hours of stress testing.

-

Scalable Synchronization:

- Supports up to 1,024 I/O points per redundant pair, making it suitable for large-scale systems.

- Real-time data mirroring via EtherNet/IP ensures identical program states between controllers.

-

Rugged Industrial Design:

- Conformal coating and reinforced connectors protect against dust, moisture, and vibration (compliant with IEC 61131-2).

- Extended temperature range (-40°C to 70°C) suits offshore, mining, and outdoor applications.

-

Easy Integration:

- Plug-and-play compatibility with GE’s Proficy Machine Edition software reduces commissioning time by 50%.

Application Areas and Use Cases

- Oil and Gas:

Deployed in offshore platforms to maintain continuous control of wellhead valves and pumps. A North Sea rig reduced shutdowns by 95% after adopting IC698CRE040-HN, saving $2M annually. - Power Generation:

Ensures uninterrupted monitoring of steam turbines in thermal power plants, preventing grid instability. - Water/Wastewater:

Redundant control of sewage treatment pumps in urban systems, avoiding environmental incidents.IC698CRE040-HN

Competitor Comparison

The IC698CRE040-HN outperforms comparable redundant modules through:

- Faster Failover: <20 ms vs. industry-standard 50–100 ms for most alternatives.

- Higher Temperature Tolerance: Operates 20°C hotter than competitors’ typical 50°C max.

- Native EtherNet/IP Support: Eliminates need for protocol gateways, reducing hardware costs by 15%.

Selection Recommendations

- System Criticality: Choose this module for systems where downtime costs >$10k/hour (e.g., oil refineries).

- Scalability: Pair with IC698CHS030 controllers for >500 I/O points; use IC698CRE020 for smaller systems.

- Budget: While 10–15% pricier than non-redundant modules, its ROI is realized within 6 months for high-risk applications.

Precautions

-

Installation:

- Use anti-static wrist straps to avoid ESD damage during installation.

- Ensure equal cable lengths between primary/secondary controllers for synchronization accuracy.

-

Maintenance:

- Verify controller synchronization weekly via Proficy software.

- Replace batteries every 5 years to maintain program memory.

-

Safety:

- Power off both controllers before replacing the module to avoid voltage spikes.

- Test failover procedures quarterly to validate redundancy logic.