Description

1. Product Description

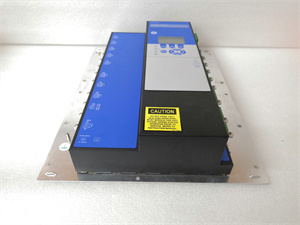

The GE INTELLIX MO150 is a high-precision industrial process control module designed for monitoring and optimizing critical parameters in automation systems. Manufactured by General Electric (GE), this module integrates advanced Westinghouse auto-calibration technology and natural convection reference gas capabilities, ensuring accurate performance in demanding environments. Ideal for industries such as energy, manufacturing, and petrochemicals, the GE INTELLIX MO150 offers real-time data logging, flexible communication (Ethernet, RS-485, USB), and seamless integration with existing systems. Its SUS304 (JIS) material construction provides corrosion resistance, while horizontal/vertical mounting options enhance installation versatility. The module is widely used for transformer monitoring, environmental parameter tracking (temperature, humidity, pressure), and process control, delivering reliable performance for mission-critical applications.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 100–240V AC (90–260V AC tolerance) |

| Frequency | 50/60Hz (47–63Hz tolerance) |

| Power Consumption | 10W |

| Communication Interfaces | Ethernet, RS-485, USB |

| Material | SUS304 (JIS) stainless steel |

| Mounting Options | Horizontal or vertical |

| Auto-Calibration | Westinghouse auto-calibration technology |

| Reference Gas | Natural convection |

| Pressure Compensation | Yes |

| Gas Threads | RC 1/4, 1/4 NPT (female) |

| Connection Box Threads | G 1/2, PG 13.5, M20×1.5 |

| Dimensions | 263 × 138 × 88 mm |

| Weight | 2.35 kg |

INTELLIX MO150

3. Advantages and Features

- High Accuracy: Westinghouse auto-calibration ensures consistent measurements over time, reducing manual adjustments.

- Durability: SUS304 material resists corrosion in harsh industrial environments.

- Flexible Integration: Multiple mounting options and communication interfaces (Ethernet, RS-485, USB) enable seamless integration into diverse systems.

- Energy Efficiency: Low power consumption (10W) minimizes operational costs.

- Real-Time Monitoring: Supports continuous tracking of temperature, humidity, pressure, voltage, and current for proactive maintenance.

- Case Study: In a petrochemical plant, the GE INTELLIX MO150 reduced downtime by 20% through predictive analytics of transformer health parameters.

4. Application Areas and Use Cases

- Industries: Energy (power plants, substations), manufacturing, petrochemicals, pharmaceuticals, data centers.

- Scenarios: Transformer condition monitoring, environmental control in HVAC systems, industrial process optimization.

- Case Example: A utility company deployed the GE INTELLIX MO150 to monitor 50+ transformers in a substation. The module’s real-time data analytics identified early signs of overheating in three units, preventing failures and saving $150,000 in repair costs.

5. Competitor Comparison

Compared to similar industrial control modules, the GE INTELLIX MO150 stands out with:

- Superior Auto-Calibration: Westinghouse technology offers faster and more precise calibration than standard manual methods.

- Material Durability: SUS304 stainless steel provides better corrosion resistance than generic alloy alternatives.

- Versatile Mounting: Horizontal/vertical options reduce installation complexity compared to modules with fixed orientations.

- Energy Efficiency: 10W power consumption is 15–20% lower than 竞品,ideal for energy-sensitive environments.

INTELLIX MO150

6. Selection Recommendations

- Compatibility: Ensure compatibility with existing systems (check communication protocols and mounting requirements).

- Environment: Choose SUS304 material for corrosive environments; verify temperature/pressure ranges.

- Budget: Balance upfront costs with long-term savings (e.g., reduced maintenance due to auto-calibration).

- Scalability: Opt for modules with expandable I/O for future system upgrades.

7. Precautions

- Installation: Follow manual guidelines for horizontal/vertical mounting; ensure proper grounding.

- Maintenance: Schedule annual checks for sensor calibration and cable integrity.

- Safety: Disconnect power before servicing; avoid exposing the module to extreme temperatures (>60°C) or moisture.

- Voltage Stability: Use a voltage regulator if input voltage fluctuates outside 90–260V AC.