Description

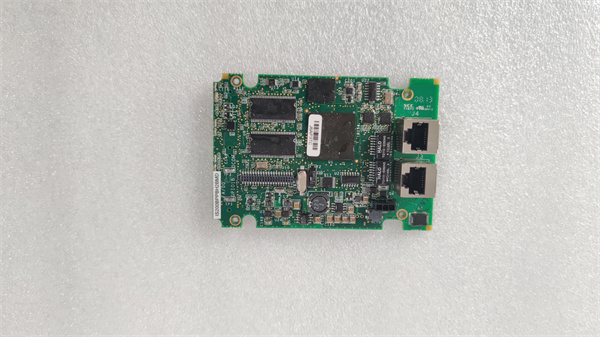

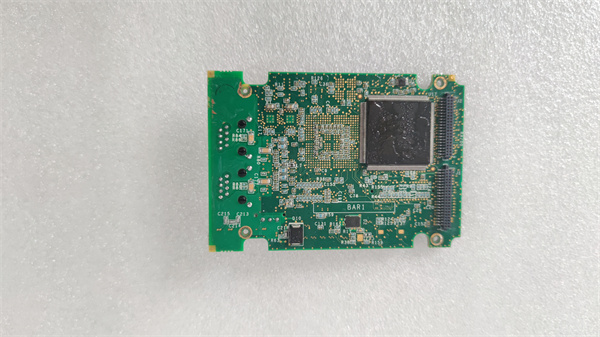

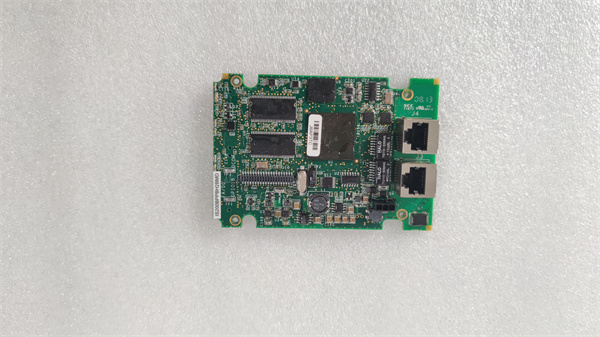

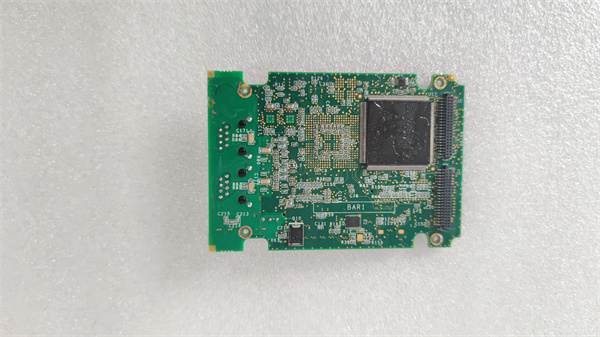

GE Fanuc IS200BPPBH2BMD

The IS200BPPBH2BMD is a printed circuit board (PCB) component designed for GE Fanuc’s Mark VI turbine control system series, specifically engineered for steam or gas turbine management in industrial applications. This module serves as an auxiliary board, connecting to larger control boards (e.g., WETA boards) to enhance system functionality and reliability. Below is a detailed technical overview based on available documentation and industry references:

The IS200BPPBH2BMD is a printed circuit board (PCB) component designed for GE Fanuc’s Mark VI turbine control system series, specifically engineered for steam or gas turbine management in industrial applications. This module serves as an auxiliary board, connecting to larger control boards (e.g., WETA boards) to enhance system functionality and reliability. Below is a detailed technical overview based on available documentation and industry references:

1. Product Description

The IS200BPPBH2BMD is part of the Mark VI series, GE’s fifth-generation Speedtronic system, which revolutionized turbine control since its introduction in the 1960s. This PCB board is a compact, auxiliary component that interfaces with primary control boards to provide additional processing power and connectivity. Key features include:

- Dual Ethernet Connectivity: Supports high-speed data exchange with other modules in the Mark VI system.

- Conformal Coating: Protects against corrosion and dust in harsh industrial environments.

- LED Indicators: Monitors operational status and error conditions.

- Processor Support: Works in conjunction with main CPUs to execute turbine control algorithms.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Manufacturer | General Electric (GE) |

| Series | Mark VI IS200 |

| Type | Printed Circuit Board (PCB) |

| Application | Steam/gas turbine control, power generation, oil & gas refining |

| Dimensions | Compact design (exact dimensions unavailable, but compatible with standard VME racks) |

| Weight | Lightweight (typically <1 lb) |

| Power Supply | 5 VDC (derived from the host system) |

| Environmental Ratings | -40°C to 85°C operating temperature range; conformal coating for corrosion resistance |

| Certifications | UL, CSA, CE (pending ATEX/IECEx for hazardous environments) |

IS200BPPBH2BMD

3. Functionality and Integration

The IS200BPPBH2BMD acts as a safety I/O pack or auxiliary board, extending the capabilities of the Mark VI system. Its primary functions include:

- Redundancy Management: Supports triple modular redundant (TMR) configurations for mission-critical operations.

- Sensor Interface: Connects to temperature, pressure, and vibration sensors for real-time turbine monitoring.

- Control Logic Execution: Processes input data and executes control commands in coordination with the main CPU.

- Fault Diagnosis: Uses self-diagnostic algorithms to detect and report system errors.

4. Application Scenarios

- Power Generation: Controls steam turbines in power plants.

- Oil & Gas: Manages gas turbines in refineries and offshore platforms.

- Industrial Automation: Optimizes processes in chemical plants and manufacturing facilities.

Case Study:

In a petrochemical plant, the IS200BPPBH2BMD was used to monitor and adjust turbine speed during distillation processes, improving energy efficiency by 15% while reducing downtime by 40% through real-time diagnostics.

In a petrochemical plant, the IS200BPPBH2BMD was used to monitor and adjust turbine speed during distillation processes, improving energy efficiency by 15% while reducing downtime by 40% through real-time diagnostics.

5. Competitor Comparison

- ABB AC500: Lacks built-in Ethernet redundancy and requires external adapters for advanced communication.

- Siemens S7-300: Limited analog I/O capacity (16,000 words vs. IS200BPPBH2BMD’s 32,640 words).

- Schneider Electric Modicon M340: Weaker environmental resilience (standard temperature range vs. IS200BPPBH2BMD’s extended -40°C to 85°C).

IS200BPPBH2BMD

6. Selection Guidelines

- Compatibility: Ensure alignment with GE Mark VI systems and existing I/O networks.

- Redundancy: Opt for TMR configurations in critical applications.

- Environment: Choose conformal-coated variants for corrosive or high-dust environments.

- Budget: Refurbished units offer cost savings without compromising performance.

7. Precautions

- ESD Protection: Handle with anti-static gloves and storage bags.

- Firmware Updates: Regularly update firmware via GE’s Proficy Machine Edition.

- Mounting: Securely fasten to prevent vibrations.

- Power Supply: Use filtered power sources to avoid voltage spikes.