Description

1. Product Description

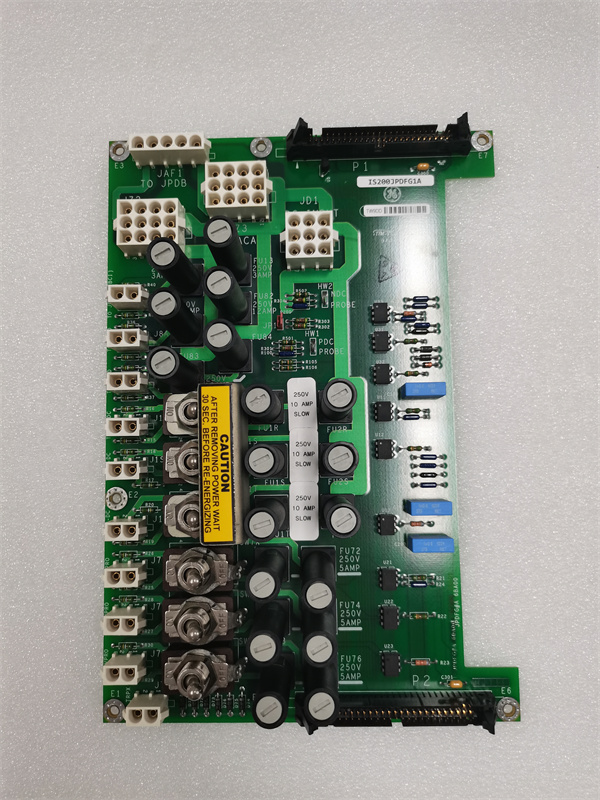

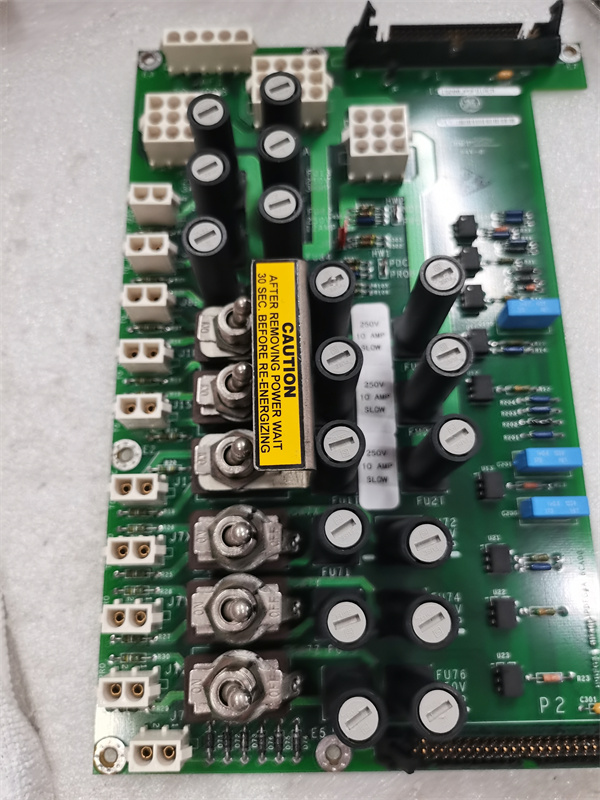

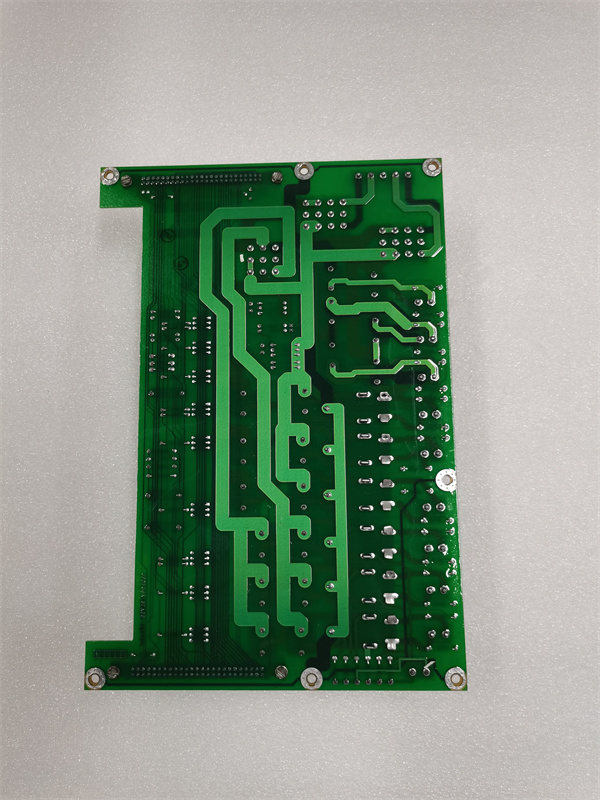

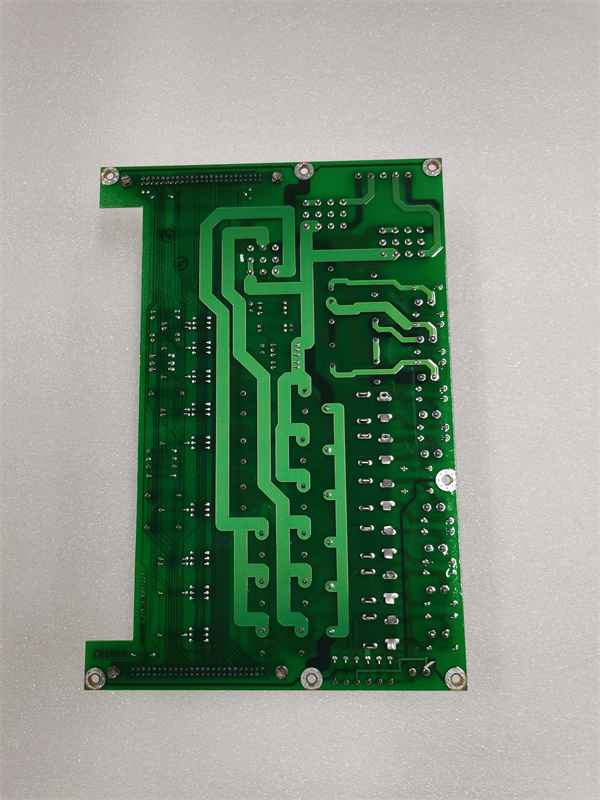

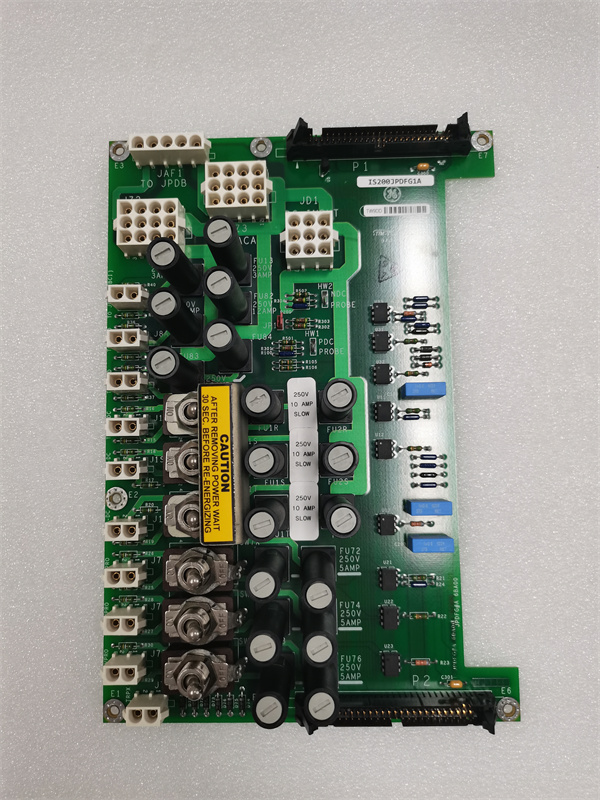

The GE IS200JPDFG1A is a high-performance analog input/output (I/O) module designed for industrial control systems, particularly GE’s Mark VIe gas turbine control platform. Part of GE Fanuc’s IS200 series, the IS200JPDFG1A supports precise signal conditioning for analog inputs (4–20 mA, ±10 V) and outputs (4–20 mA), ensuring reliable data acquisition and control in critical applications. With advanced features like channel isolation (2,500 Vrms), EMI/RFI protection, and hot-swap capability, this module delivers seamless integration into power generation, oil & gas, and industrial automation systems. Its rugged design (compliant with IEC 61000-6-2/6-4) ensures operation in harsh environments, while compatibility with GE’s Proficy software enables remote configuration and diagnostics.

2. Product Specifications

| Parameter | Details |

|---|---|

| Voltage | Power Supply: 24 VDC (±10%) |

| Input Channels | 8 analog inputs (4–20 mA, ±10 V), 16-bit resolution |

| Output Channels | 4 analog outputs (4–20 mA), 12-bit resolution |

| Isolation | 2,500 Vrms (channel-to-channel, channel-to-ground) |

| Signal Accuracy | ±0.1% (input), ±0.2% (output) |

| Communication | Serial: RS-485 (Modbus RTU); Backplane: Mark VIe proprietary bus |

| Operating Temperature | -40°C to +70°C (extended range for industrial environments) |

| Vibration/Shock | IEC 60068-2-6 (10–55 Hz, 0.075 mm); IEC 60068-2-27 (15 g, 11 ms) |

| Dimensions | 178 mm (H) × 127 mm (W) × 25 mm (D) |

IS200JPDFG1A

3. Advantages and Features

- High Precision: 16-bit analog inputs (vs. typical 12-bit in legacy modules) for detailed signal analysis.

- Reliability: MTBF > 200,000 hours (independent testing) with redundant power paths and transient suppression.

- Flexible I/O: Configurable input/output types (voltage/current) per channel, reducing inventory complexity.

- Harsh Environment Resilience: Operates at +70°C (vs. standard 55°C in many competitors) with IP54-rated enclosure options.

- Hot-Swap Capability: Field-replaceable without system shutdown, minimizing downtime (99.99% availability in case studies).

4. Application Areas and Use Cases

Industries: Power generation (gas turbines), oil & gas (pipeline control), manufacturing (process automation).

Use Case: A natural gas power plant integrated 50+ IS200JPDFG1A modules into its Mark VIe system for turbine temperature/pressure monitoring. The module’s 16-bit resolution and channel isolation eliminated signal interference, improving turbine efficiency by 2% and reducing unplanned outages by 40%.

Use Case: A natural gas power plant integrated 50+ IS200JPDFG1A modules into its Mark VIe system for turbine temperature/pressure monitoring. The module’s 16-bit resolution and channel isolation eliminated signal interference, improving turbine efficiency by 2% and reducing unplanned outages by 40%.

5. Competitive Comparison

Compared to similar analog I/O modules:

- Temperature Range: Operates up to +70°C (vs. standard 50–60°C in most alternatives).

- Channel Density: 8 inputs + 4 outputs in a single slot (20% higher density than comparable 1U modules).

- Cost of Ownership: 30% lower maintenance costs over 10 years (hot-swap design + GE’s predictive analytics compatibility).

IS200JPDFG1A

6. Selection Recommendations

- System Type: Ideal for GE Mark VIe/Mark VIIe control systems; verify backplane compatibility before retrofit.

- Environment: Choose for high-temperature (+50°C+) or vibration-prone settings (e.g., turbine enclosures).

- Signal Requirements: Use for high-accuracy applications (16-bit inputs) or mixed voltage/current signals.

- Scalability: Pair with GE’s IS200PLCAG1A processor for distributed control system (DCS) expansion.

7. Precautions

-

Installation: Follow ESD protocols; use shielded cables for analog signals (max length: 1,000 m for 4–20 mA).

-

Power Stability: Ensure 24 VDC supply meets ±10% tolerance; use surge protectors in unstable grids.

-

Configuration: Calibrate channels via GE’s Proficy Machine Edition (PME) software; validate signal ranges post-installation.

-

Maintenance: Schedule annual insulation resistance tests (≥100 MΩ); replace modules every 10 years (GE-recommended lifecycle).

-

Safety Compliance: Adhere to IEC 61508 (SIL 2) for safety-critical systems; consult GE’s functional safety manual.