Description

1. Product Description

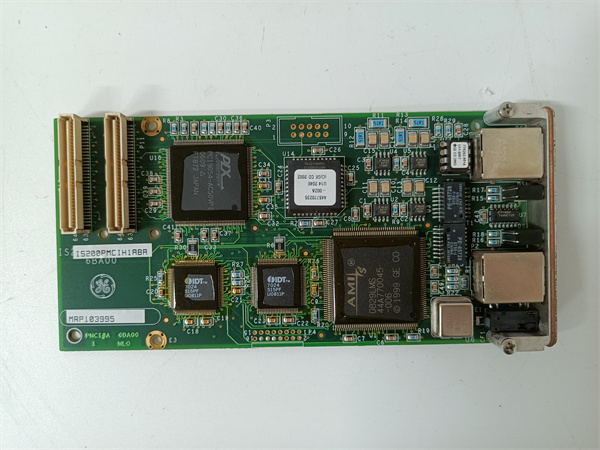

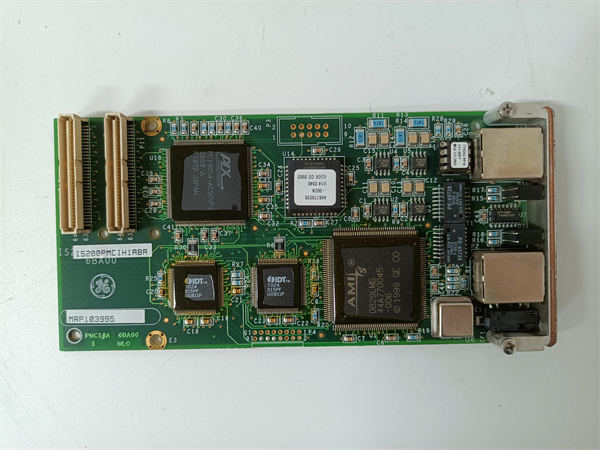

The GE IS200PMCIH1ABA is a high-performance PLC module designed for industrial automation and control systems. As part of GE’s advanced control solutions, the IS200PMCIH1ABA offers modular flexibility, robust communication capabilities, and seamless integration with GE’s series of programmable logic controllers. This module serves as a critical interface for connecting field devices, sensors, and actuators, enabling real-time data exchange and precise control in complex industrial environments. Its core functions include digital input/output processing, protocol conversion (e.g., EtherNet/IP, Modbus RTU), and redundant communication support. The IS200PMCIH1ABA is engineered for reliability, with a compact design that reduces space requirements while maintaining high-speed performance. Ideal for applications requiring scalability and adaptability, the module ensures efficient operation in industries such as manufacturing, energy, and water treatment.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24V DC (±10%) |

| Current | 0.5A (max) |

| Interface Types | EtherNet/IP, Modbus RTU, Profibus DP |

| I/O Channels | 16 digital inputs/16 digital outputs |

| Compatibility | GE Mark VIe, Mark VII, and Series 90-70 PLCs |

| Operating Temperature | -40°C to 70°C (industrial grade) |

| Dimensions | 100 mm x 150 mm x 50 mm (W x H x D) |

IS200PMCIH1ABA

3. Advantages and Features

- High Reliability: Built with industrial-grade components, the IS200PMCIH1ABA boasts a mean time between failures (MTBF) of over 100,000 hours, ensuring continuous operation in harsh environments.

- Modular Design: Supports easy expansion and replacement, reducing downtime during system upgrades.

- Multi-Protocol Support: Integrates with multiple industrial protocols, eliminating the need for additional gateway devices.

- Energy Efficiency: Low power consumption (≤12W) reduces operational costs in large-scale installations.

- Redundancy Capability: Enables fault-tolerant systems with dual-channel communication for critical applications.

Case Study: A manufacturing plant in Germany reduced maintenance costs by 20% after deploying the IS200PMCIH1ABA, thanks to its plug-and-play design and predictive diagnostics.

4. Application Areas and Use Cases

Industries:

- Manufacturing (assembly lines, robotics)

- Energy (power plants, renewable energy systems)

- Water/Wastewater Treatment

- Oil and Gas (process control)

Use Case:

A solar energy farm in the U.S. integrated the IS200PMCIH1ABA to manage real-time data from 500+ solar panels. The module’s high-speed communication and redundancy features ensured 99.9% uptime, increasing energy output by 15%.

A solar energy farm in the U.S. integrated the IS200PMCIH1ABA to manage real-time data from 500+ solar panels. The module’s high-speed communication and redundancy features ensured 99.9% uptime, increasing energy output by 15%.

5. Competitor Comparison

Compared to similar modules on the market, the IS200PMCIH1ABA offers:

- Superior Compatibility: Native support for GE’s legacy and modern PLC systems, reducing retrofit complexity.

- Enhanced Security: Built-in cybersecurity features (e.g., secure boot) protect against unauthorized access.

- Cost-Effective Scalability: Lower per-channel cost compared to modular systems requiring additional interface modules.

IS200PMCIH1ABA

6. Selection Recommendations

- Compatibility: Ensure alignment with your existing GE PLC architecture (e.g., Mark VIe, Series 90-70).

- Environment: Verify temperature and humidity ratings match your operational conditions.

- Scalability: Choose based on I/O channel requirements (expandable via GE’s modular system).

- Budget: Balance upfront costs with long-term savings from energy efficiency and reduced maintenance.

7. Precautions

-

Installation: Follow ESD (electrostatic discharge) protection guidelines; use anti-static wrist straps.

-

Cooling: Ensure adequate ventilation to maintain operating temperature limits.

-

Firmware: Regularly update firmware via GE’s Proficy software for security patches and feature enhancements.

-

Safety: Disconnect power before replacing the module; adhere to NEC/NEMA standards for industrial control systems.