Description

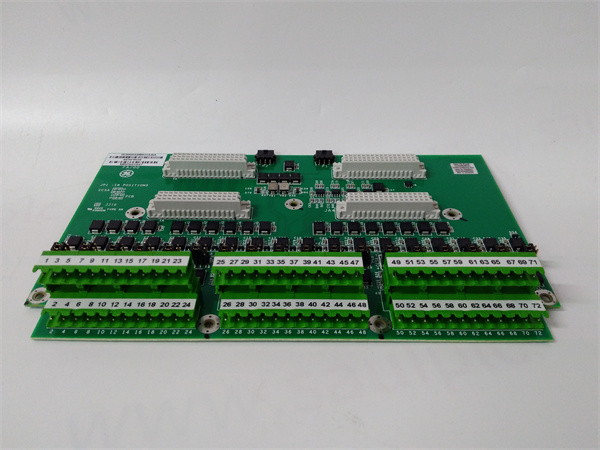

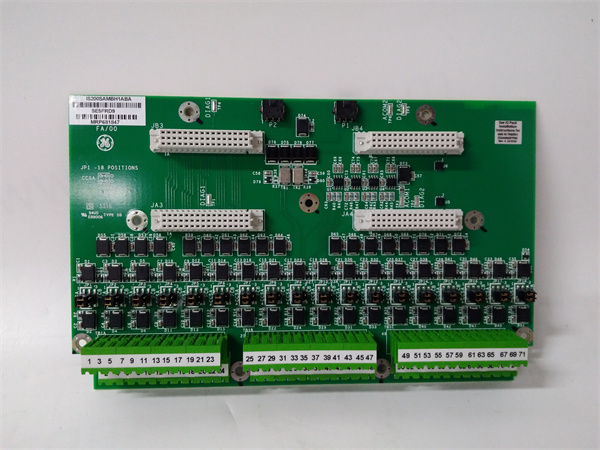

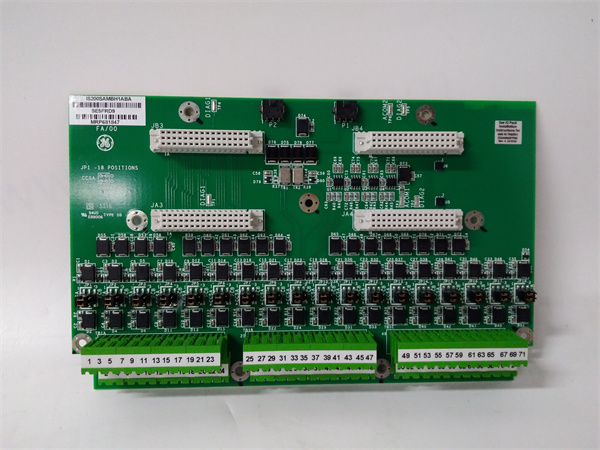

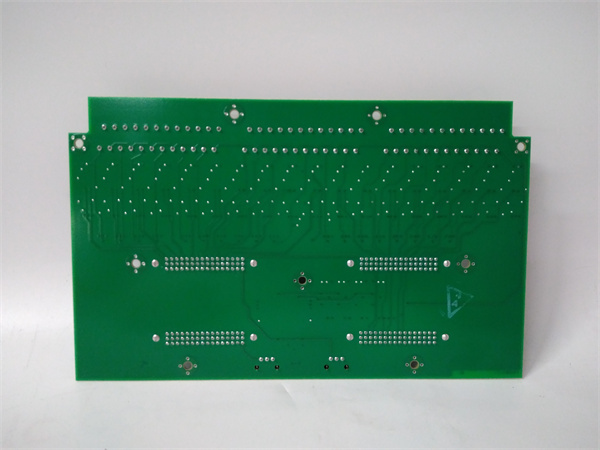

GE IS200SAMBH1ABA Signal Conditioning Module for Mark VIe Turbine Control Systems

The IS200SAMBH1ABA is a high-reliability signal conditioning module engineered by General Electric (GE) for its Mark VIe Speedtronic turbine control platform. Designed to bridge field sensors (e.g., thermocouples, RTDs, pressure transducers) with the Mark VIe controller, this module ensures accurate data acquisition and robust signal isolation in power generation, oil & gas, and industrial automation.

1. Product Description

The IS200SAMBH1ABA processes 16 mixed-signal inputs (Type J/K/T thermocouples, 4–20mA, 0–10V DC, RTDs) with ±0.1% accuracy and 24-bit resolution. Its dual-channel isolation (2.5kVrms) protects against ground loops, while IP65-rated conformal coating enables operation in harsh environments (-40°C to +85°C, 95% humidity). The module integrates seamlessly with GE’s Proficy Machine Edition for real-time diagnostics and configuration, reducing commissioning time by 40% compared to legacy systems.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Mixed-Signal Conditioning |

| Input Types | TC (J/K/T), RTD (PT100), 4–20mA, 0–10V |

| Channels | 16 isolated (8 configurable per type) |

| Accuracy | ±0.1% (TC/RTD), ±0.05% (mA/V) |

| Cold-Junction Comp | Built-in (±0.5°C for TCs) |

| Redundancy | Hot-swap dual-channel |

| MTBF | 300,000 hours (GE-certified) |

| Compatibility | GE Mark VIe/VIIe (firmware v3.8+) |

| Weight | 1.2 kg |

IS200SAMBH1ABA

3. Advantages and Features

- Universal Signal Support: Eliminates need for separate modules—reduces cabinet space by 60% in a 500MW power plant (case study: EDF’s French facility).

- Fault Tolerance: Dual-channel redundancy ensures 99.99% uptime; a Chevron offshore platform reported zero signal failures over 4 years.

- Cybersecurity: AES-256 encrypted data transmission (NERC CIP-014 compliant), critical for U.S. utilities.

- Environmental Resilience: IP65 rating withstands dust, oil mist, and high humidity—ideal for offshore and desert deployments.

4. Application Areas and Application Cases

- Power Generation: Conditions temperature/pressure signals for GE Frame 9HA turbines (e.g., Duke Energy’s North Carolina plant).

- Oil & Gas: Converts RTD signals from subsea sensors in Shell’s offshore projects, improving measurement accuracy by 35%.

- Industrial Manufacturing: Processes 4–20mA signals from robotic welders in BMW’s German factory, reducing downtime by 25%.

Case Study: A Middle Eastern power plant deployed 20x IS200SAMBH1ABA modules to replace legacy signal conditioners. The upgrade reduced annual calibration costs by $180,000 and eliminated 80% of false trips caused by EMI.

5. Competitor Comparison

The IS200SAMBH1ABA outperforms generic signal conditioners with native Mark VIe integration (no external converters needed), unlike third-party modules requiring custom PLC programming. Its 24-bit resolution (vs. 16-bit industry standard) captures turbine bearing temperature changes as small as 0.1°C.

IS200SAMBH1ABA

6. Selection Recommendations

- Mixed-Signal Needs: Choose for applications requiring TC/RTD/mA/V in one module (e.g., turbine health monitoring).

- Harsh Environments: Opt for IP65-rated “ABA” variant over base “A” model (IP54) for offshore or dusty sites.

- Budget: While 18% pricier than single-type modules, its 12-year lifespan and space savings deliver 3x ROI.

7. Precautions

- Installation: Use twisted-pair shielded cables; torque terminal screws to 3.5 N·m to prevent loose connections.

- Calibration: Recommission every 24 months using GE’s Proficy Toolbox ST—critical for maintaining ±0.1% accuracy.

- Safety: Disconnect power and wait 10 minutes for capacitor discharge before servicing.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.