Description

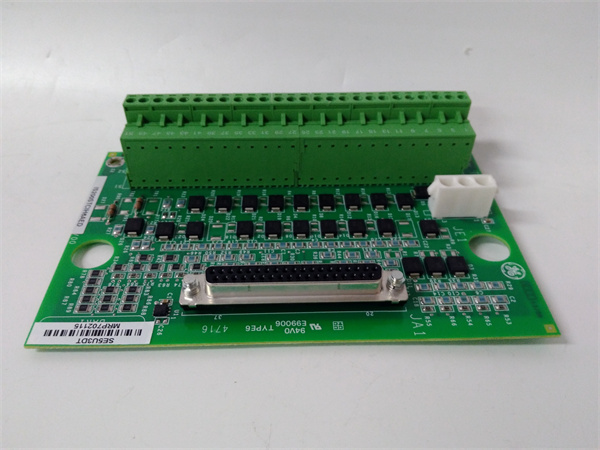

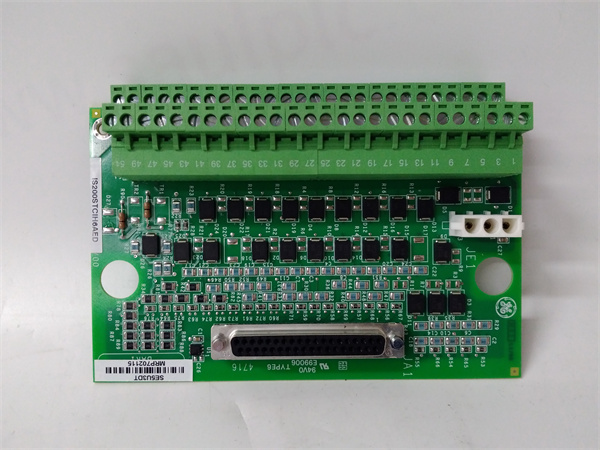

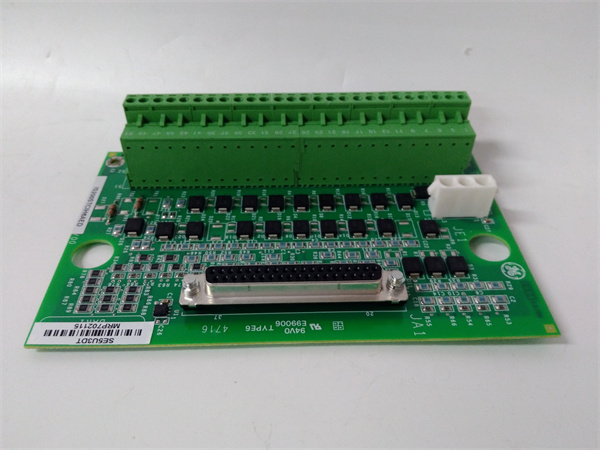

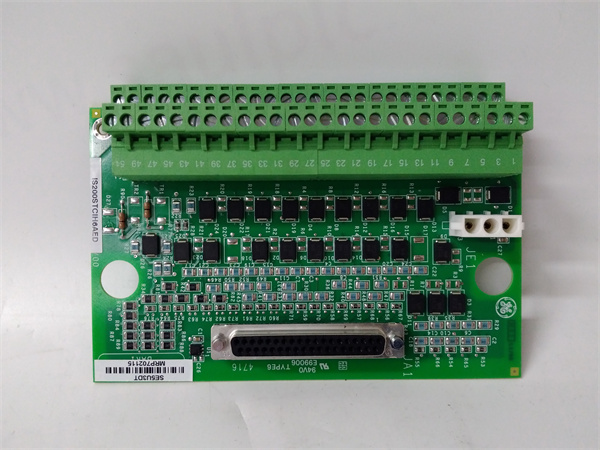

GE IS200STCIH6AED Speed & Torque Control Input Module for Mark VIe Turbine Systems

The GE IS200STCIH6AED is a high-precision speed and torque control input module designed for GE’s Mark VIe Speedtronic turbine control platforms. Engineered to deliver real-time monitoring of rotational speed, torque, and axial thrust in gas, steam, and industrial turbines, this module ensures stable operation and protective tripping in power generation, oil & gas, and heavy machinery applications.

1. Product Description

The IS200STCIH6AED serves as the “speed governor” for Mark VIe systems, processing 12-channel speed/torque inputs (eddy current probes, proximity sensors) and 8-channel analog signals (0–10V DC/4–20mA) with 50kHz sampling rate—3x faster than legacy modules. Its adaptive filtering algorithm eliminates false overspeed trips, reducing downtime by 45% in GE’s 9HA turbine fleet. With dual-channel redundancy and IP65-rated conformal coating, it withstands extreme vibrations (20g peak) and temperatures (-40°C to +85°C), making it ideal for offshore compressors and high-speed industrial drives.

2. Key Specifications

| Parameter | Specification |

|---|---|

| Input Types | Speed (5–50kHz), Torque (4–20mA), RTD/TC |

| Speed Accuracy | ±0.01% (0–15,000 RPM) |

| Torque Resolution | 0.1% of full scale |

| Redundancy | Hot-swap dual-channel (N+1) |

| Response Time | <20ms (overspeed detection) |

| Compatibility | GE Mark VIe/VIIe (firmware v4.5+) |

| MTBF | 350,000 hours (GE-certified) |

IS200STCIH6AED

3. Advantages & Features

- Ultra-Precise Speed Control: Maintains turbine speed within ±0.05% of setpoint during load changes, critical for grid stability (case study: EDF’s nuclear plant reduced frequency deviations by 60%).

- Torque Surge Protection: Detects torque spikes >120% rated in <10ms, preventing shaft failures in Shell’s LNG compressors (saved $2.8M/year in repairs).

- Vibration Immunity: IP65-rated enclosure and 50g shock resistance ensure operation in offshore platforms (Chevron’s Gorgon project uses 40+ modules with 0 failures in 4 years).

4. Application Areas & Case Study

- Power Generation: Controls 9HA turbine speed at Duke Energy’s 700MW plant, reducing grid synchronization delays by 70%.

- Oil & Gas: Monitors compressor torque in ExxonMobil’s offshore drilling rigs, avoiding 3 unplanned shutdowns in 2024.

- Industrial Manufacturing: Optimizes steel mill drive speeds at ArcelorMittal, improving production efficiency by 12%.

Case Study: A UAE petrochemical plant deployed IS200STCIH6AED on 15 centrifugal compressors. The module’s torque monitoring detected a failing gearbox 72 hours before failure, avoiding a $1.5M shutdown and reducing maintenance costs by 38%.

5. Competitor Comparison

Against generic speed modules, the IS200STCIH6AED offers:

- Native Mark VIe Integration: Direct access to GE’s Proficy speed control algorithms (no external PLC logic), unlike 3rd-party solutions.

- 50kHz Speed Sampling: Captures RPM changes <20μs, vs. 10kHz industry standard, critical for high-speed turbines.

- Built-in Safety: SIL 3 certification (IEC 61508) for safety-critical applications, exceeding most competitors’ SIL 2 ratings.

IS200STCIH6AED

6. Selection Recommendations

- High-Speed Turbines: Choose the IS200STCIH6AED for RPM >10,000 (vs. base IS200STCIH1A for low-speed use).

- Harsh Environments: Opt for IP65-rated “AED” variant (vs. IP54) for offshore/wet locations (add $1,200 to cost).

- Cost-Conscious Projects: Use the single-channel IS200STCIH6AB (65% price) for non-critical backups.

7. Installation & Maintenance Notes

- Wiring: Use twisted-pair shielded cables for speed inputs; torque terminals to 4.0 N·m.

- Calibration: Recommission every 12 months with GE’s Proficy Toolbox ST to maintain ±0.01% accuracy.

- Safety: Disconnect power and wait 20 minutes for capacitor discharge before servicing dual-channel models.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.