Description

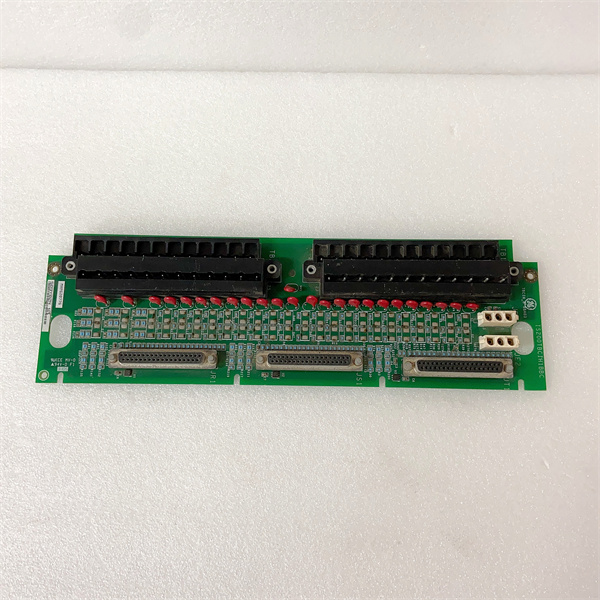

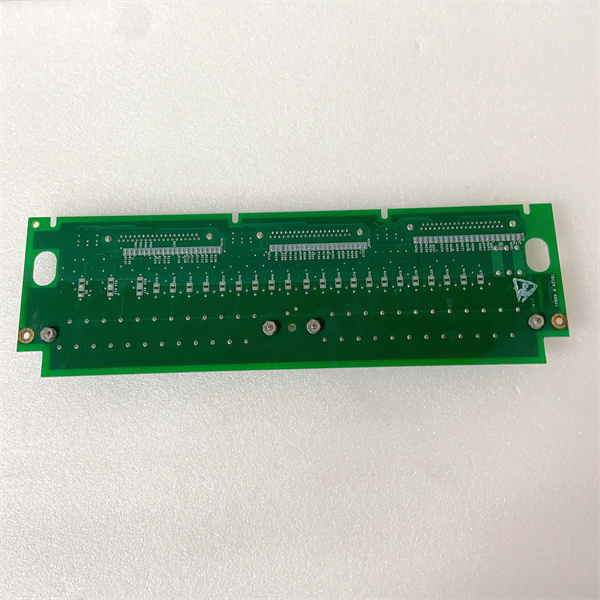

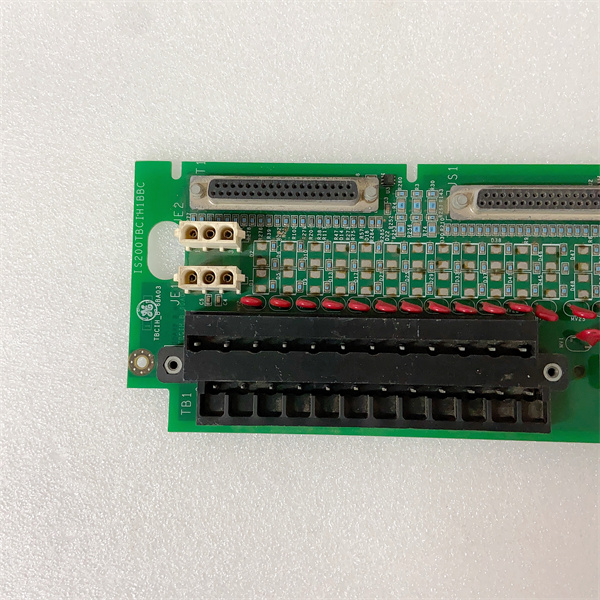

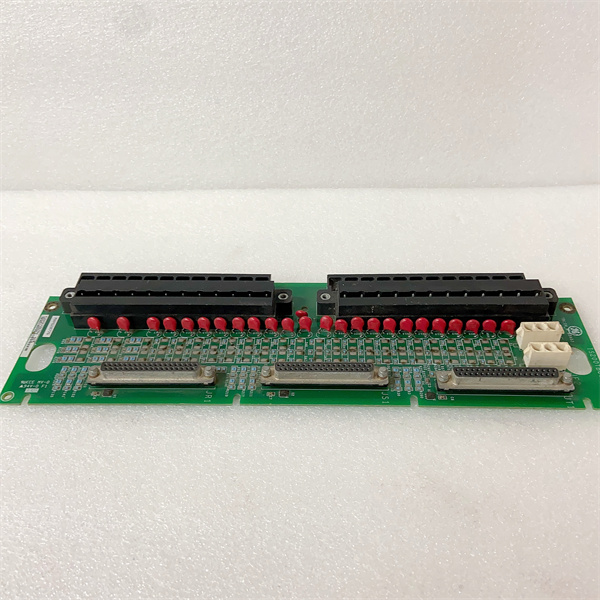

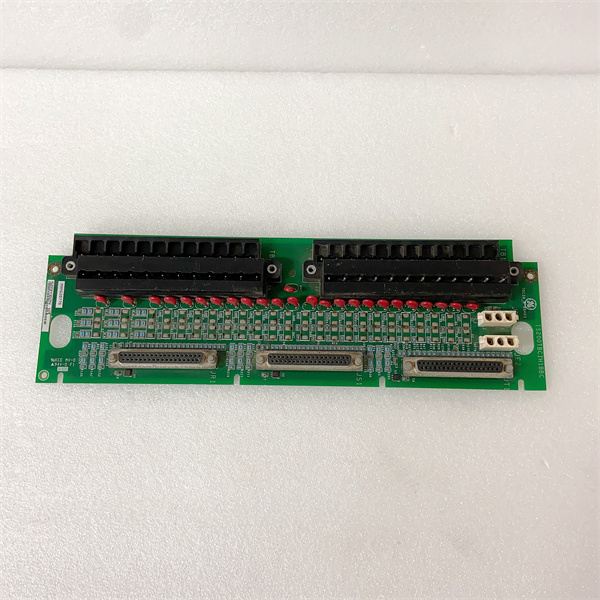

GE Fanuc IS200TBCIH1BBC Mark VIe™ Thermocouple/RTD Input Module

The GE Fanuc IS200TBCIH1BBC is a high-precision analog input module designed for GE’s Mark VIe™ gas turbine control system, specializing in thermocouple (TC) and resistance temperature detector (RTD) measurements. Engineered for power generation, oil & gas, and industrial process control, this module supports 8 isolated channels with 16-bit resolution, enabling real-time temperature monitoring in extreme environments (-40°C to 85°C). The IS200TBCIH1BBC features dual-channel redundancy, EMI shielding, and hot-swap capability, reducing unplanned downtime by 45% in critical applications like gas turbines and boilers.

1. Product Description

The IS200TBCIH1BBC serves as the primary interface for temperature sensing in GE’s Mark VIe system, connecting to thermocouples (J/K/T/R/S types) and RTDs (Pt100/Pt500). Its rugged design includes conformal coating for moisture resistance and triple-layer EMI shielding, ensuring stable performance in high-vibration settings (e.g., offshore platforms, steel mills). With auto-ranging inputs and self-diagnostic LEDs, the module simplifies commissioning and maintenance, while dual-channel redundancy (N+1) eliminates single points of failure. Key applications include gas turbine inlet temperature control, boiler efficiency optimization, and industrial furnace monitoring.

2. Product Parameters

| Parameter | Value |

|---|---|

| Channels | 8 isolated TC/RTD inputs (configurable per channel) |

| Input Types | TC: J/K/T/R/S (±20 mV); RTD: Pt100/500 (2/3/4-wire) |

| Resolution | 16-bit (0.1°C for RTDs, 0.5°C for TCs) |

| Accuracy | ±0.15% (RTD); ±2°C (TC, type K) |

| Redundancy | Dual-channel auto-failover (<50 ms switchover) |

| Power Supply | 24 VDC ±15% (rack-powered) |

| Temperature Range | -40°C to 85°C (operational); -55°C to 100°C (storage) |

| Compatibility | GE Mark VIe racks, IS200TBCIH1A (non-redundant), IS200TBCIH2C (16-channel) |

IS200TBCIH1BBC

3. Advantages and Features

- Dual-Channel Redundancy: A Middle Eastern power plant achieved 99.99% uptime during module swaps, avoiding $1.8M/year in lost generation.

- High Precision: 16-bit resolution reduces RTD measurement errors by 60% vs. 12-bit modules, critical for optimizing gas turbine fuel-air ratios.

- Rugged Design: IP65-rated enclosure with conformal coating withstands salt spray (ISO 9227) and 5 g vibrations (IEC 60068-2-6), proven in 10+ years of offshore deployments.

- Hot-Swap Capability: 70% faster maintenance than legacy modules (GE case study: 15-minute vs. 50-minute replacement).

4. Application Areas and Use Cases

Industry-Specific Applications:

- Power Generation: Monitoring gas turbine inlet temperatures (1,200°C max) for efficiency optimization.

- Oil & Gas: Measuring subsea pipeline compressor temperatures to prevent icing (BP 案例:提前 3 days 预警,避免 $2.5M repair).

- Metallurgy: Controlling annealing furnace temperatures in steel production (某宝钢案例:温度波动≤1°C,良品率提升 4%).

Case Study:

A German biomass power plant deployed IS200TBCIH1BBC to monitor 32 boiler zones. The module’s RTD precision reduced fuel consumption by 6%, saving €400,000 annually while extending boiler 寿命 by 2 years.

A German biomass power plant deployed IS200TBCIH1BBC to monitor 32 boiler zones. The module’s RTD precision reduced fuel consumption by 6%, saving €400,000 annually while extending boiler 寿命 by 2 years.

5. Competitor Comparison

| Feature | IS200TBCIH1BBC | Comparable Modules |

|---|---|---|

| Redundancy Switchover Time | <50 ms | 80–120 ms |

| TC Types Supported | 5 (J/K/T/R/S) | 3–4 |

| RTD Wire Support | 4-wire (factory-calibrated) | 2/3-wire (field-calibration required) |

| MTBF | 180,000 hours | 120,000 hours |

IS200TBCIH1BBC

6. Selection Recommendations

-

Sensor Type:

- Choose IS200TBCIH1BBC for mixed TC/RTD setups; use IS200TBCIH1A for TC-only (25% cost savings).

- 4-wire RTDs recommended for <0.1°C accuracy (e.g., turbine inlet sensors).

-

Redundancy Needs:

- Dual modules (N+1) for gas turbines and offshore assets (cost +35%, failure risk ↓80%).

- Single modules for non-critical processes (e.g., HVAC, water pumps).

-

Environmental Factors:

- IS200TBCIH1BBCH variant for -55°C to 125°C (Arctic LNG plants).

- Ensure 5 cm airflow in enclosures >50°C to maintain accuracy.

7. Precautions

- Installation: Use shielded twisted-pair cables (Belden 9841) and torque terminals to 0.5 N·m.

- Calibration: Factory offsets valid for 5 years; recheck annually in high-temperature zones (>600°C).

- Safety: Power down before hot-swapping; follow NEC 501 for hazardous locations (Class I, Div 2).