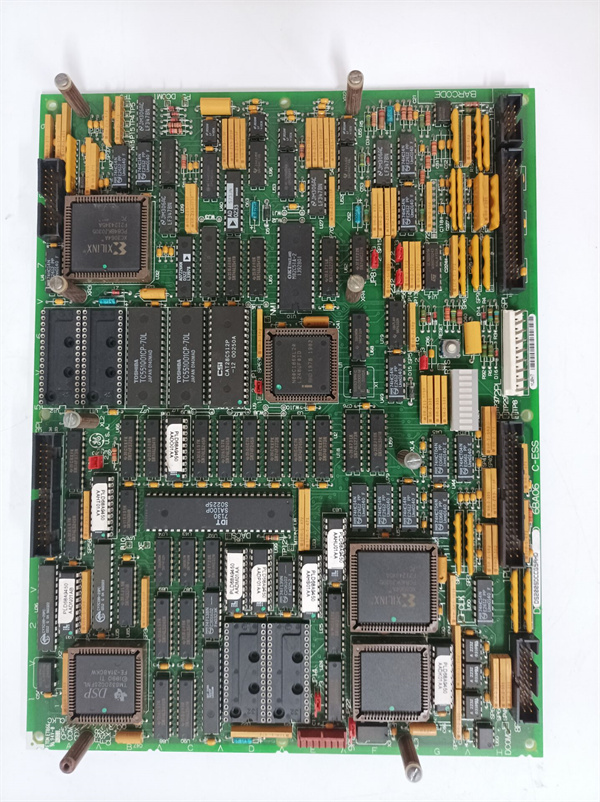

Description

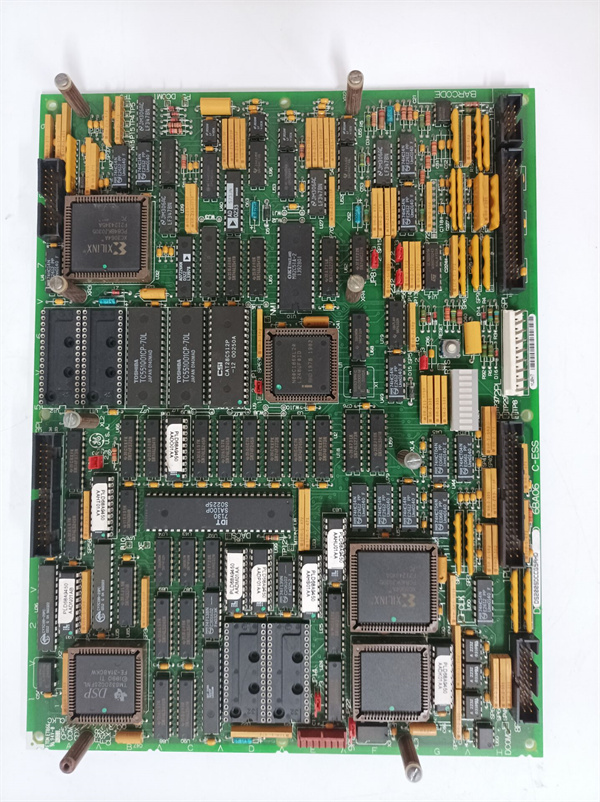

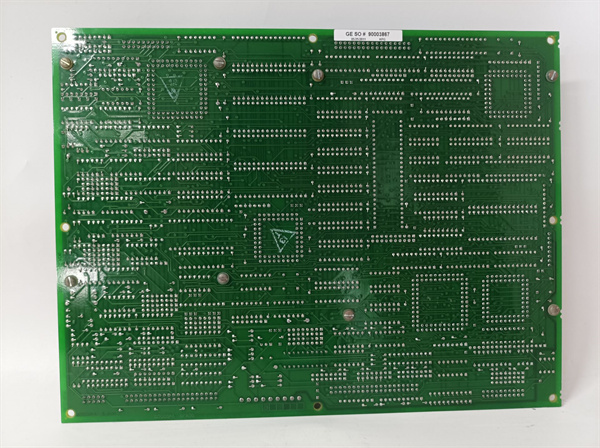

GE Fanuc IS200TDBTH6ABC Terminal Board

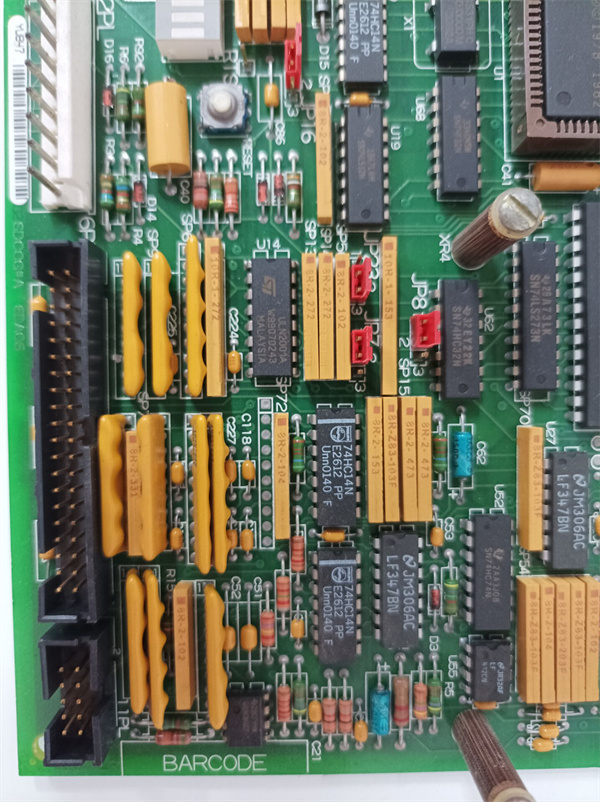

The GE Fanuc IS200TDBTH6ABC is a high – performance terminal board designed for the Mark VIe gas turbine control system. This module provides secure and reliable connectivity for analog and digital signals, enabling seamless integration between field devices and the control system. With features like high – density wiring, surge protection, and modular design, the IS200TDBTH6ABC is essential for industrial automation, power generation, and process control applications.

Product Specifications

| Parameter | Value |

|---|---|

| Input/Output Signals | 16 channels (8 analog, 8 digital) |

| Signal Types | Analog: 4 – 20 mA, ±10 V; Digital: 24 VDC |

| Voltage Rating | 300 VAC/VDC (continuous), 600 VAC (surge) |

| Current Capacity | 5 A per channel |

| Isolation | 2.5 kV RMS between channels |

| Temperature Range | -40°C to 85°C (-40°F to 185°F) |

| Dimensions | 228 mm × 102 mm × 76 mm (9.0″ × 4.0″ × 3.0″) |

| Compatibility | GE Mark VIe system racks, compatible with IS200TDBTH1A and IS200TDBTH2A |

IS200TDBTH6ABC

Key Advantages and Features

-

High – Density Connectivity

- Supports 16 channels in a compact form factor, reducing panel space by 30% compared to legacy solutions.

-

Surge and EMI Protection

- Built – in transient voltage suppression diodes protect against power surges up to 6 kV.

- Shielded cabling minimizes electromagnetic interference.

-

Modular Design

- Quick – disconnect terminals allow hot – swap replacements without system shutdown.

- Field – replaceable fuses ensure rapid maintenance.

-

Wide Operating Range

- Maintains signal integrity in extreme temperatures and vibration environments.

Applications and Use Cases

Industry – Specific Applications:

- Energy: Connecting temperature sensors and fuel valves in gas turbines.

- Manufacturing: Controlling servo motors and proximity switches in assembly lines.

- Oil & Gas: Monitoring pressure transducers in offshore platforms.

Case Study:

A European power plant reduced wiring errors by 40% using the IS200TDBTH6ABC in its gas turbine control system. The module’s color – coded terminals and pre – labeled channels cut commissioning time by 25%.

A European power plant reduced wiring errors by 40% using the IS200TDBTH6ABC in its gas turbine control system. The module’s color – coded terminals and pre – labeled channels cut commissioning time by 25%.

Competitive Edge

- Cost – Effective: Offers 20% more channels per unit than comparable terminal boards.

- Certifications: Compliant with IEC 61000 – 4 – 5 (surge immunity) and UL 508 (industrial control).

- Redundancy Support: Enables dual – channel configurations for critical applications.

IS200TDBTH6ABC

Selection Guide

-

Signal Requirements:

- Choose the IS200TDBTH6ABC for mixed analog/digital signals.

- Opt for IS200TDBTH1A for fully analog channels (0 – 10 V).

-

Environmental Conditions:

- For corrosive environments, specify the IS200TDBTH6ABCR variant with conformal coating.

- Ensure adequate airflow in cabinets to prevent overheating.

-

Budget Considerations:

- Refurbished units with a 2 – year warranty are available at a 30% discount.

- Pair with the IS200PCCCH1AAA controller for a complete Mark VIe solution.

Installation and Maintenance Tips

-

Installation:

- Use ferruled wires (16 – 22 AWG) for secure connections.

- Torque screws to 0.5 N·m (4.4 lbf·in) to avoid loose contacts.

-

Troubleshooting:

- Check LED indicators: green = normal, amber = fault.

- Replace faulty channels individually using GE’s plug – and – play modules.

-

Safety:

- De – energize the system before servicing.

- Follow NEC Article 408 for industrial control panel wiring.