Description

1. Product Description

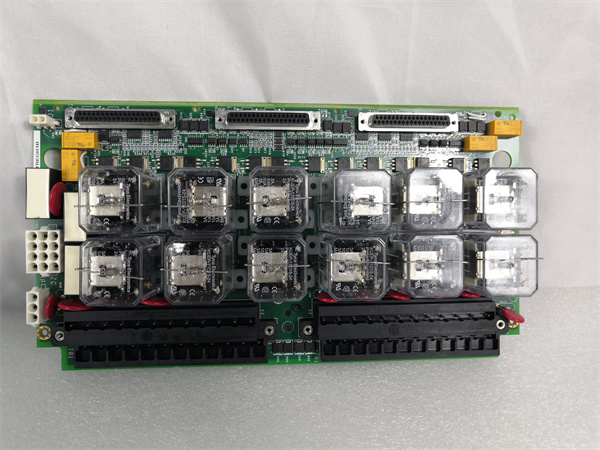

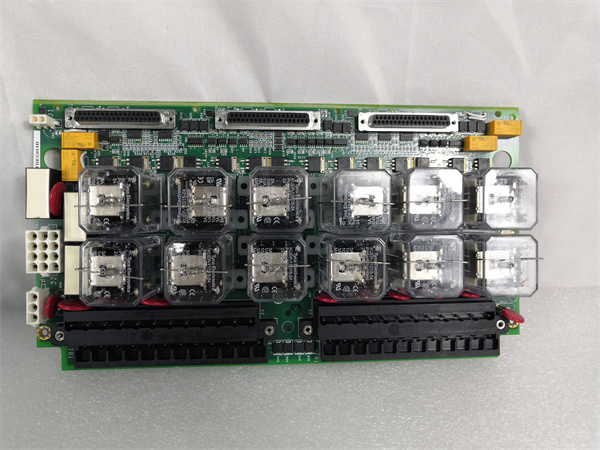

The IS200TREGH1B serves as the interface between the I/O controller and emergency trip solenoids, providing positive power supply (via JX1, JY1, JZ1 connectors) while collaborating with the TRPG board for negative power. It features 12 relays (3 groups of 3) to execute 跳闸 logic, supporting simplex, dual, or triple-redundant configurations. Key advantages include high reliability (industrial-grade components, redundant power), fast response times (millisecond-level trip activation), and modular design for easy maintenance. The IS200TREGH1B is widely used in gas turbine control systems to protect equipment and personnel during emergencies.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | General Electric (GE) |

| Series | Mark VI Speedtronic |

| Type | Turbine Emergency Terminal Board |

| Power Supply | 200–250V AC (control), 70–145V DC (bus) |

| Trip Solenoids | 3 (positive power supply) |

| Channels | 6 |

| Operating Temperature | 0°C to 70°C |

| Weight | 2.00 lbs (0.9 kg) |

| Dimensions | 17.8 cm (width) × 33.02 cm (depth) |

| Redundancy Support | Simplex, dual, triple |

| Connector Types | J1 (2-pin, trip signal), J2 (12-pin, power) |

IS200TREGH1B

3. Advantages and Features

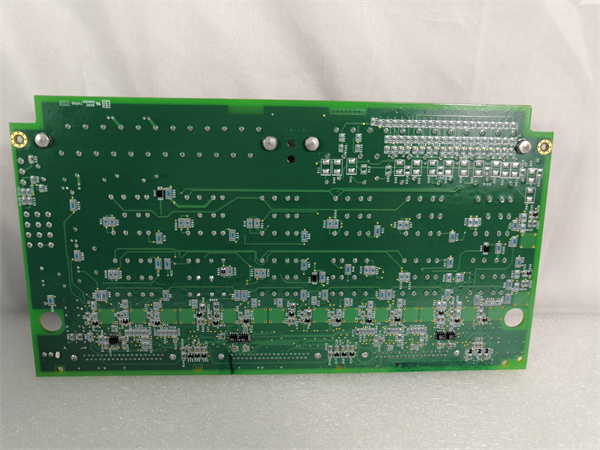

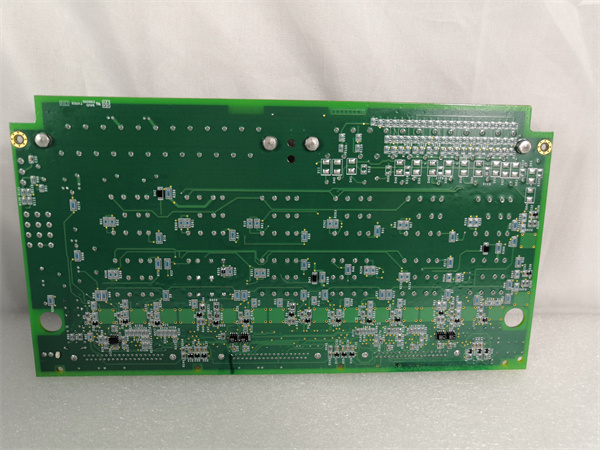

- High Reliability: Multilayer PCB with SMD components, metal oxide varistors (MOVs) for voltage protection, and redundant power supply (diode-combined from JX1/JY1/JZ1) ensure stable operation in harsh environments.

- Fast Response: Industrial-grade relays enable sub-100ms trip activation, critical for emergency scenarios.

- Modular Design: Detachable 48-terminal blocks and cable-connected PPRO module simplify installation and maintenance.

- Safety Compliance: Meets power industry standards (e.g., CE, RoHS) and integrates with GE’s QNX-based control systems for secure status feedback.

4. Application Fields and Cases

Industries: Power generation (gas turbines), petrochemical processing, industrial automation.

Case Study: A 500MW gas turbine power plant in the U.S. integrated the IS200TREGH1B in a triple-redundant configuration. During a grid instability event, the board triggered emergency shutdowns within 80ms, preventing turbine damage and ensuring personnel safety. The modular design reduced maintenance downtime by 30% compared to legacy systems.

Case Study: A 500MW gas turbine power plant in the U.S. integrated the IS200TREGH1B in a triple-redundant configuration. During a grid instability event, the board triggered emergency shutdowns within 80ms, preventing turbine damage and ensuring personnel safety. The modular design reduced maintenance downtime by 30% compared to legacy systems.

5. Competitor Comparison

Compared to similar emergency trip boards, the IS200TREGH1B offers superior redundancy flexibility (supporting triple systems) and voltage range (70–145V DC bus), adapting to diverse industrial setups. Its integrated MOVs and transformer protection (12 transparent-encapsulated transformers) reduce component failure rates by 20% versus 竞品 with basic surge protection.

IS200TREGH1B

6. Selection Recommendations

- Compatibility: Ensure alignment with Mark VI systems (check PPRO module compatibility).

- Redundancy Needs: Choose simplex/dual/triple configurations based on safety criticality (e.g., triple for nuclear or high-risk applications).

- Environment: Verify temperature range (0–70°C) and storage conditions (anti-static packaging).

- Budget: Balance new vs. refurbished options (refurbished units often include 1–3 year warranties).

7. Precautions

- Installation: Follow GE’s wiring diagrams (e.g., J1 for trip signals, J2 for power) to avoid misconnections.

- ESD Protection: Use anti-static gloves and storage boxes; avoid direct contact with PCB components.

- Maintenance: Regularly inspect relays and terminals for corrosion; test redundancy logic annually.

- Version Check: Confirm revision (e.g., H1B for 125V DC) matches system requirements.