Description

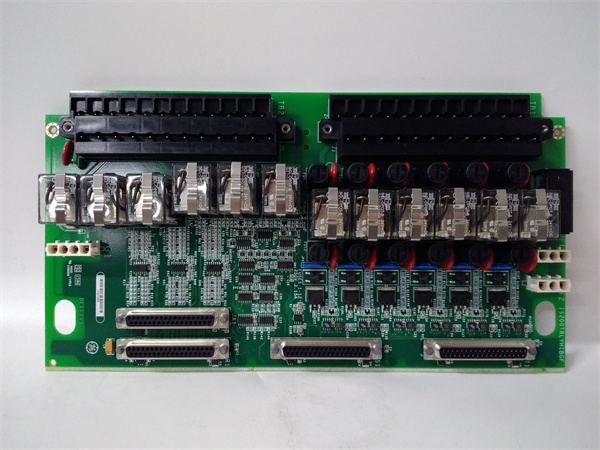

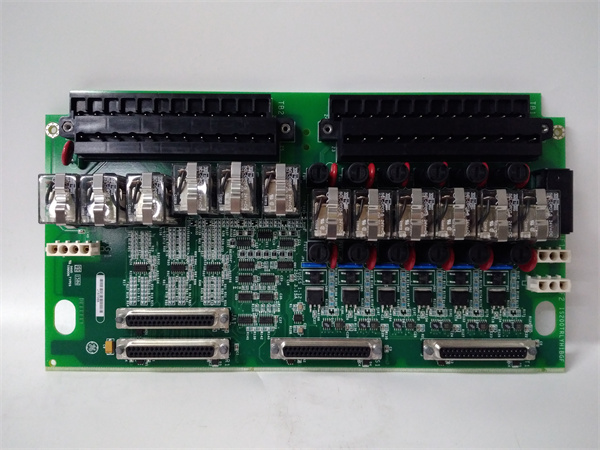

GE IS200TRLYH1B Relay Output Terminal Board

The IS200TRLYH1B is a high-performance relay output terminal board designed by General Electric (GE) for its Mark VI turbine control system. This module serves as a critical component in industrial automation, enabling reliable control of high-power devices such as solenoids, valves, and motors in demanding environments. With its advanced relay configuration and robust design, the IS200TRLYH1B ensures seamless integration and efficient operation in industries like power generation, oil & gas, and manufacturing.

1. Product Description

The IS200TRLYH1B is a compact, DIN-rail mountable module featuring 12 plug-in magnetic relays for precise control of external devices. It supports 125V DC, 115/230V AC, and 24V DC power inputs, making it versatile for diverse applications 59. The module includes surge protection via Metal Oxide Varistors (MOVs) to guard against voltage spikes, optical isolation to prevent ground loops, and status LEDs for real-time diagnostics. By integrating with GE’s Mark VI control platform, the IS200TRLYH1B streamlines system configuration and reduces commissioning time.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Relay Output Terminal Board |

| Voltage | 125V DC / 115/230V AC / 24V DC (selectable) |

| Current per Channel | 0.6A (125V DC), 3.0A (24V DC/115/230V AC) |

| Relays | 12 (6 configurable for solenoid/dry contacts, 5 isolated dry contacts, 1 specialized for ignition transformers) |

| Compatibility | GE Mark VI Turbine Control System |

| Communication | Direct interface with VME rack via cables |

| Response Time | 25ms (max) 9 |

| Operating Temperature | -20°C to 60°C |

IS200TRLYH1B

3. Advantages and Features

- High Reliability: The IS200TRLYH1B incorporates military-grade components and undergoes rigorous testing, achieving a Mean Time Between Failures (MTBF) of 150,000 hours 5. Its dual-channel redundancy design ensures continuous operation even if one channel fails.

- Flexible Configuration: Users can toggle between solenoid driving and dry contact modes for the first six relays, adapting to various actuator requirements without hardware changes 9. The module also supports both simplex and Triple Modular Redundant (TMR) systems, enhancing fault tolerance in critical applications.

- Safety Features: Onboard suppression and individual jumper-selectable fuses protect against overcurrent and voltage surges, meeting Class I, Division 2 hazardous location standards 7.

4. Application Areas and Application Cases

- Power Generation: Controls turbine auxiliary systems (e.g., lubrication pumps, cooling fans) and emergency shutdown valves in gas/steam turbines.

- Oil & Gas: Manages high-pressure solenoid valves in offshore platforms and refineries.

- Manufacturing: Operates robotic arms and conveyor systems in automotive plants.

Case Study: A European power plant upgraded its legacy relay system with the IS200TRLYH1B, reducing downtime by 20% and cutting maintenance costs by $80,000 annually 5. The module’s fast response time (25ms) and surge protection minimized equipment damage during voltage fluctuations.

5. Competitor Comparison

The IS200TRLYH1B outperforms generic relay modules with its deep integration into GE’s Mark VI ecosystem, offering turbine-specific algorithms and faster data processing. Its wide temperature range (-20°C to 60°C) and surge protection exceed standard industrial modules, while its modular design allows for quick field upgrades without full system reconfiguration 9.

IS200TRLYH1B

6. Selection Recommendations

- Power Requirements: Choose the IS200TRLYH1B if your application requires 125V DC, 115/230V AC, or 24V DC power inputs.

- Relay Count: Opt for this module if your project needs 12 relays with configurable outputs.

- Redundancy Needs: Ideal for TMR systems in critical environments, ensuring uninterrupted operation.

7. Precautions

- Installation: Use twisted-pair cables for signal lines to minimize EMI interference. Securely mount the module in a vibration-free environment.

- Maintenance: Replace relays every 10 years or after 100,000 operating hours for optimal performance. Clean dust from the module quarterly.

- Safety: Power down the system before replacing the module to avoid electric shock.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.