Description

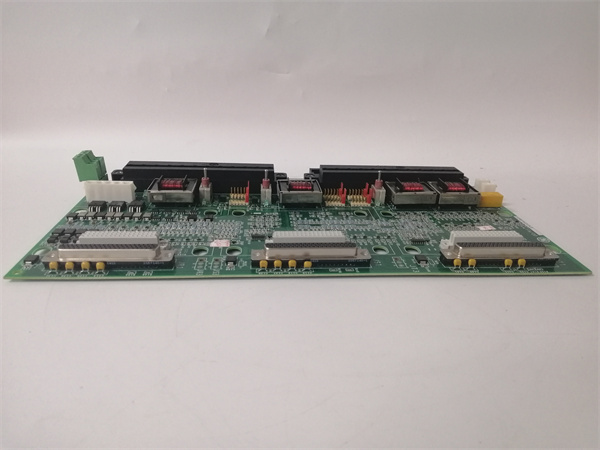

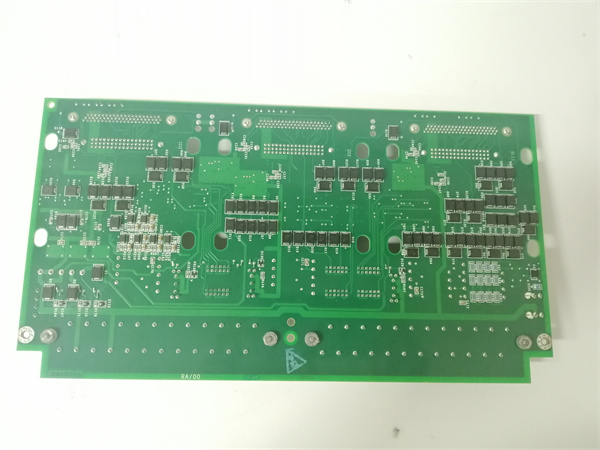

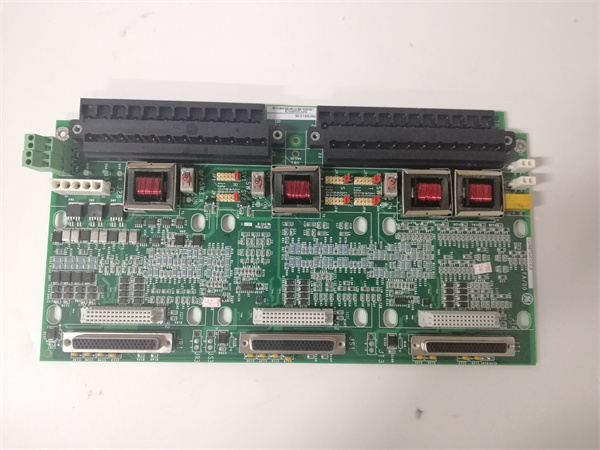

IS200TSVCH1A Product Documentation

1. Product Overview

The IS200TSVCH1A is a high-precision temperature and speed control module designed for industrial automation systems, particularly in machinery and process control applications. Manufactured by GE Fanuc, this module is part of the IS200 series, recognized for its durability and advanced performance in harsh operating conditions. The IS200TSVCH1A integrates real-time monitoring and adaptive control algorithms to ensure stable operation, making it ideal for critical processes requiring precise temperature and speed regulation. Its compatibility with GE’s Mark VIe and Mark VIIe systems enhances its versatility in retrofitting or expanding existing setups.

The IS200TSVCH1A is a high-precision temperature and speed control module designed for industrial automation systems, particularly in machinery and process control applications. Manufactured by GE Fanuc, this module is part of the IS200 series, recognized for its durability and advanced performance in harsh operating conditions. The IS200TSVCH1A integrates real-time monitoring and adaptive control algorithms to ensure stable operation, making it ideal for critical processes requiring precise temperature and speed regulation. Its compatibility with GE’s Mark VIe and Mark VIIe systems enhances its versatility in retrofitting or expanding existing setups.

2. Technical Specifications

| Parameter | Details |

|---|---|

| Voltage Range | 100–240V AC, 50/60Hz |

| Current Rating | 3A (continuous), 6A (peak) |

| Input Channels | 6 analog inputs (0–10V DC/4–20mA) |

| Output Channels | 4 PWM outputs (0–10V DC) |

| Communication Interface | Ethernet/IP, Profibus DP |

| Compatibility | GE Mark VIe, Mark VIIe systems |

| Operating Temperature | -20°C to +60°C |

IS200TSVCH1A

3. Key Advantages & Features

- Dual-Function Control: Simultaneously manages temperature and speed with ±0.1% accuracy, reducing system complexity.

- Adaptive Algorithms: Automatically adjusts parameters based on load changes, improving energy efficiency by up to 20%.

- Modular Design: Supports expansion via plug-and-play I/O modules for scalable configurations.

- Fault Tolerance: Built-in redundancy ensures uninterrupted operation even during sensor or component failures.

4. Application Areas & Use Cases

The IS200TSVCH1A is widely used in:

The IS200TSVCH1A is widely used in:

- Manufacturing machinery (e.g., extruders, conveyor systems).

- HVAC systems in commercial buildings.

- Petrochemical processing plants.

Case Study: A North American manufacturing facility implemented the IS200TSVCH1A in their extrusion line, achieving a 25% reduction in temperature-related product defects and a 15% improvement in production throughput.

5. Competitor Comparison

Compared to similar modules, the IS200TSVCH1A offers:

Compared to similar modules, the IS200TSVCH1A offers:

- Faster response time (≤15ms vs. industry average of 25ms).

- Higher channel density (6 inputs vs. typical 4 inputs).

- Lower latency in Ethernet communication (≤1ms vs. 3ms).

IS200TSVCH1A

6. Selection Recommendations

- Functionality: Confirm if temperature/speed control is required for your application.

- System Integration: Verify compatibility with your existing GE control platform.

- Environmental Needs: Choose modules with appropriate temperature ratings for extreme conditions.

7. Installation & Maintenance Notes

- Safety: Power off the system before connecting/disconnecting the module.

- Calibration: Perform biannual checks using GE’s Proficy software for optimal accuracy.

- EMI Protection: Shield cables to prevent interference in high-noise environments.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.