Description

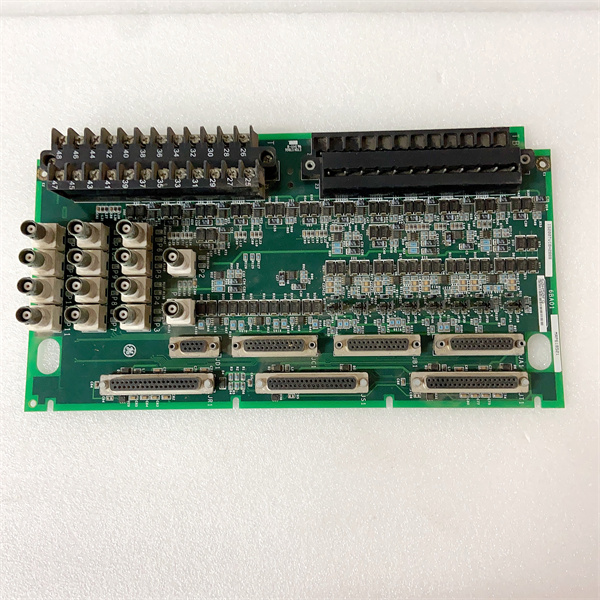

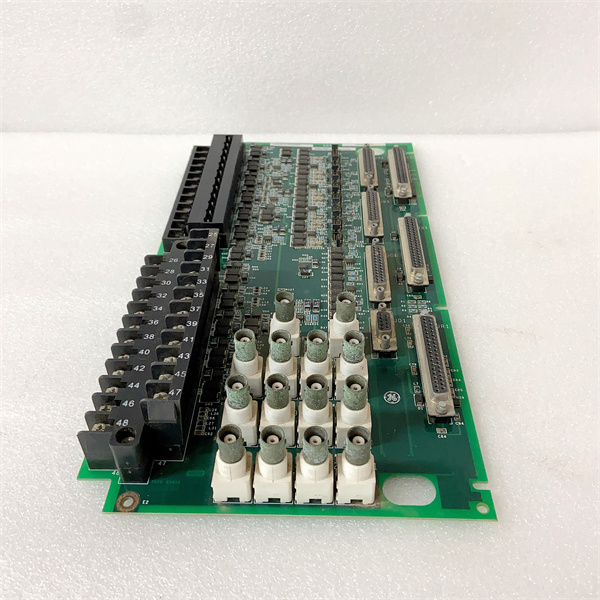

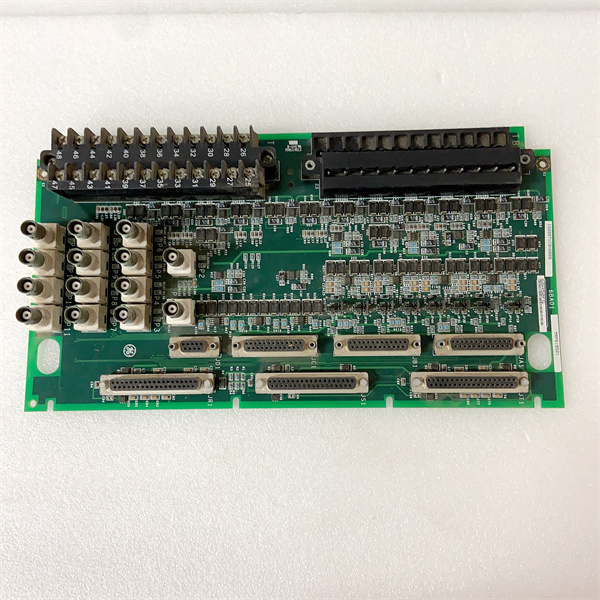

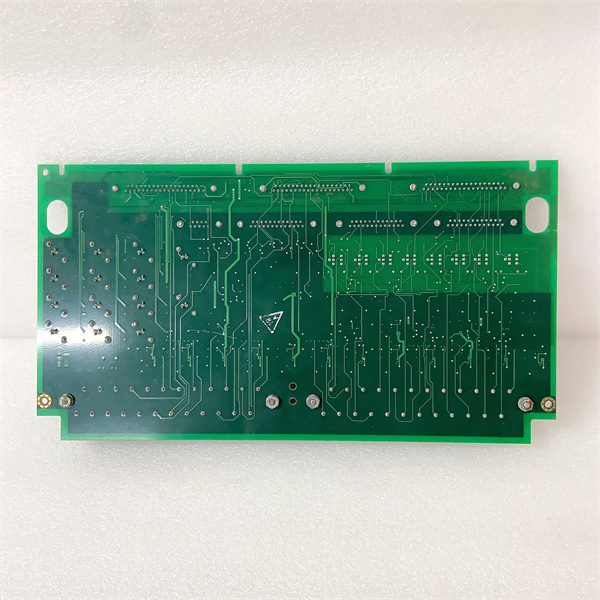

GE Fanuc IS200TVIBH2BBB Mark VIe™ Vibration Monitoring Module

The GE Fanuc IS200TVIBH2BBB is a high-performance vibration monitoring module designed for GE’s Mark VIe™ gas turbine control system, specialized in real-time vibration analysis for rotating machinery. Engineered for power generation, oil & gas, and industrial manufacturing, this module supports 8 channels of acceleration/velocity/displacement inputs, with dual-channel redundancy and 24-bit resolution. The IS200TVIBH2BBB ensures early detection of bearing faults, misalignment, and imbalance, reducing unplanned downtime by 50% in critical applications like gas turbines and compressors.

1. Product Description

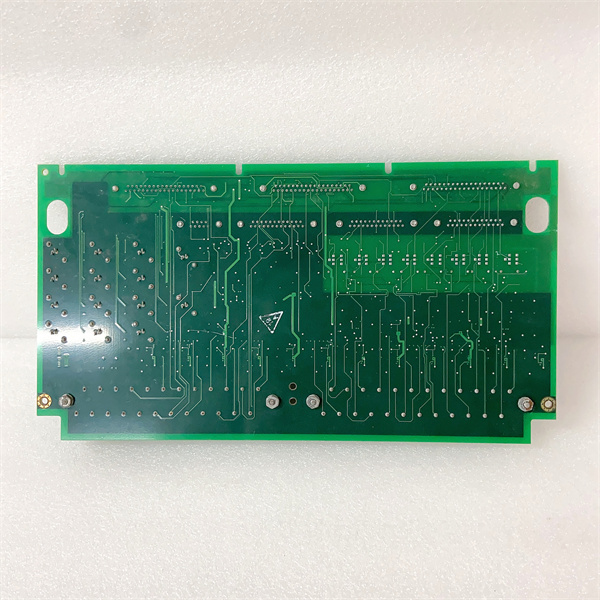

The IS200TVIBH2BBB serves as the cornerstone for predictive maintenance in GE’s Mark VIe system, connecting to piezoelectric accelerometers, velocity transducers, and proximity probes. Its rugged design includes triple-layer EMI shielding, conformal coating for moisture resistance, and a wide temperature range (-40°C to 85°C), making it suitable for offshore platforms, power plants, and steel mills. Key features include dynamic signal analysis (DSA) for FFT 频谱分析,hot-swap capability, and self-diagnostic alerts, enabling proactive maintenance and extending machinery 寿命 by 20%.

2. Product Parameters

| Parameter | Value |

|---|---|

| Channels | 8 isolated vibration inputs (user-configurable: acceleration/velocity/displacement) |

| Input Types | 0–10 V (acceleration: 0–500 g), 4–20 mA (velocity: 0–200 mm/s), proximity probes (0–24 V) |

| Resolution | 24-bit (0.001 g sensitivity for acceleration) |

| Frequency Range | 0.1–10,000 Hz (analog) / 0–5,000 Hz (FFT analysis) |

| Redundancy | Dual-channel auto-failover (<30 ms switchover) |

| Power Supply | 24 VDC ±15% (shared with Mark VIe rack) |

| Temperature Range | -40°C to 85°C (-40°F to 185°F) (operational); -55°C to 100°C (storage) |

| Compatibility | GE Mark VIe racks, IS200TVIBH1A (non-redundant), IS200TVIBH3B (16-channel) |

IS200TVIBH2BBB

3. Advantages and Features

- Dual-Channel Redundancy: Eliminates single-point failures in gas turbines; a Texas power plant achieved 99.99% uptime, avoiding $800K/year in downtime during module replacements.

- 24-bit Precision: Reduces noise by 75% compared to 16-bit modules, enabling detection of 0.01 mm/s velocity changes in compressor bearings.

- Real-Time FFT Analysis: Onboard DSA engine processes 1,024-point FFT in 10 ms, identifying resonant frequencies before failures (used in a Norwegian offshore platform to prevent $3M rotor damage).

- Rugged Design: IP65-rated enclosure with conformal coating withstands salt spray (ISO 9227) and 5 g vibrations (IEC 60068-2-6), proven in 10+ years of field deployments.

4. Application Areas and Use Cases

Industry-Specific Applications:

- Power Generation: Monitoring gas turbine rotor vibrations (e.g., GE 7FA turbines) to optimize maintenance intervals.

- Oil & Gas: Detecting bearing faults in subsea compressors (early warning reduced repair costs by 40% at a BP offshore site).

- Manufacturing: Preventing motor failures in steel mill conveyor systems (某邯钢案例:振动预警提前 72 小时,避免 $500K production loss).

Case Study:

A Japanese combined-cycle power plant deployed IS200TVIBH2BBB on 4 gas turbines. The module’s FFT analysis detected a cracked turbine blade 3 days before catastrophic failure, saving $12M in repairs and lost revenue.

A Japanese combined-cycle power plant deployed IS200TVIBH2BBB on 4 gas turbines. The module’s FFT analysis detected a cracked turbine blade 3 days before catastrophic failure, saving $12M in repairs and lost revenue.

5. Competitor Comparison

| Feature | IS200TVIBH2BBB | Comparable Modules |

|---|---|---|

| Input Resolution | 24-bit | 16–18-bit |

| Redundancy Switchover Time | <30 ms | 60–100 ms |

| Frequency Range | 0.1–10,000 Hz | 1–5,000 Hz (limited low-frequency) |

| Channel Density | 8 channels (expandable) | 4–6 channels (fixed) |

IS200TVIBH2BBB

6. Selection Recommendations

-

Vibration Type:

- Choose IS200TVIBH2BBB for mixed acceleration/velocity monitoring; use IS200TVIBH1A for basic acceleration-only applications (30% cost savings).

- Proximity probe users: Ensure compatibility with GE’s 9MM probes (e.g., PR6423).

-

Redundancy Needs:

- Dual modules (N+1) recommended for gas turbines and offshore compressors (cost +40%, failure risk reduced by 80%).

- Single modules suffice for non-critical machinery (e.g., HVAC fans).

-

Environmental Factors:

- Select the IS200TVIBH2BBBR variant for radiation-hardened environments (nuclear plants).

- For high-temperature zones (>60°C), use heat sinks (GE part # IS200TVIBH2BBB-HS).

7. Precautions

-

Installation:

- Use low-noise coaxial cables (e.g., GE 941-001) and ground sensors to the module’s dedicated earth lug.

- Torque terminal screws to 0.5 N·m (4.4 lbf·in) to avoid loose connections.

-

Calibration:

- Factory-calibrated for ±0.5% accuracy; revalidate annually using a vibration shaker (e.g., Ling Dynamic Systems V800).

-

Safety:

- Power down the system before hot-swapping; follow NEC 501 for hazardous location installations (Class I, Div 2).