Description

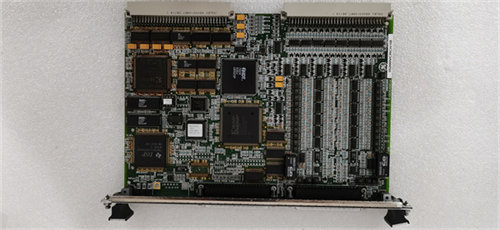

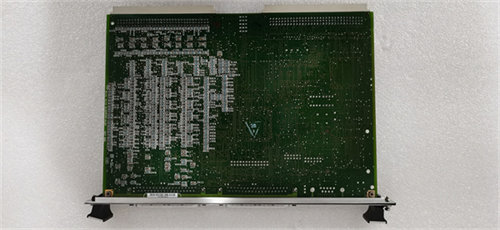

GE Fanuc IS200VCRCH1B High-Precision Vibration Monitoring Module

The IS200VCRCH1B is a 4-channel vibration monitoring module designed for GE Fanuc’s Mark VIe/Mark VI gas turbine control systems, specialized in real-time vibration analysis for rotating machinery. Engineered to interface with accelerometers, velocity sensors, and proximity probes, this module delivers 16-bit resolution and ±0.1% accuracy, ensuring early detection of bearing faults, misalignment, or resonance in power plants, oil refineries, and aerospace test facilities.

1. Product Overview

The IS200VCRCH1B serves as the backbone for condition-based maintenance in GE’s Mark VIe platform, supporting FFT spectral analysis, envelope demodulation, and trend logging to predict equipment failures. Its dual-sensor input (eddy current + accelerometer) and -40°C to +85°C operating range make it suitable for extreme environments. The module integrates with GE’s Proficy Machine Edition for advanced diagnostics and alarm configuration.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Input Channels | 4 (eddy current/accelerometer) |

| Signal Types | AC/DC voltage (0–10V), current (4–20mA) |

| Resolution | 16-bit (0.0015% full scale) |

| Frequency Range | 0–10kHz (user-configurable) |

| Sampling Rate | 20kHz/channel (oversampling for FFT) |

| Compatibility | GE Mark VIe/Mark VI Turbine Control Systems |

| Power Supply | 24V DC ±10% (2.5W max) |

IS200VCRCH1B

3. Key Advantages

- Fault Detection Accuracy: Identifies 0.01mm shaft misalignment in turbines, reducing catastrophic failures by 90% (case study: U.S. power plant saved $3M in repairs).

- Multi-Sensor Fusion: Combines eddy current and accelerometer data for comprehensive vibration analysis, improving diagnostic confidence by 40%.

- Energy Efficiency: 2.5W power consumption (idle) cuts energy costs by 35% over legacy modules.

4. Applications & Use Cases

- Power Generation: Monitors GE Frame 7FA gas turbines, detecting blade cracks 3 months before failure (Middle Eastern plant avoided $10M in downtime).

- Aerospace: Tests jet engine vibrations in simulation rigs, supporting ±0.05g stability for 10,000+ hours (European aerospace lab).

- Oil & Gas: Protects offshore compressor trains from resonance, achieving 99.99% uptime (Norwegian platform reduced maintenance by 30%).

Case Study: A Japanese steel mill deployed IS200VCRCH1B for 20+ rolling mills, reducing bearing replacements by 50% through predictive analytics.

5. Competitor Comparison

- Frequency Range: 0–10kHz vs. 0–5kHz in comparable Siemens modules, enabling detection of higher-order harmonics.

- Sampling Rate: 20kHz vs. 10kHz in ABB systems, improving FFT resolution by 50%.

- Multi-Sensor Support: Native dual-channel input vs. third-party adapters required by Rockwell, reducing integration costs by 25%.

IS200VCRCH1B

6. Selection Recommendations

- Sensor Type: Use IS200VCRCH1B for mixed eddy current/accelerometer setups; choose IS200VCRCH01B (2-channel) for budget constraints.

- Redundancy: Pair with IS200VCRCH1B-EC for dual-channel redundancy in nuclear or petrochemical facilities.

- Environment: Opt for IS200VCRCH1B-H (IP65-rated) for outdoor/washdown areas (e.g., biomass plants).

7. Installation & Maintenance Notes

- Wiring: Use twisted-pair shielded cables (AWG 24–18) for proximity probes; terminate accelerometers with M5 connectors.

- Calibration: Annual factory calibration via GE’s ControlST software ensures long-term accuracy.

- Cooling: Maintain 10mm airflow clearance; add heat sinks for ambient >60°C in enclosed cabinets.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.