Description

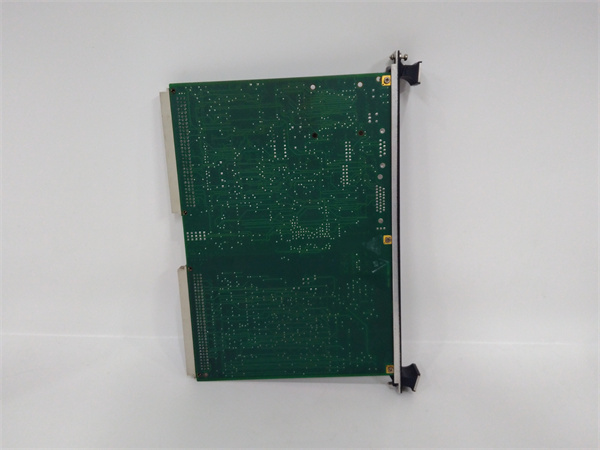

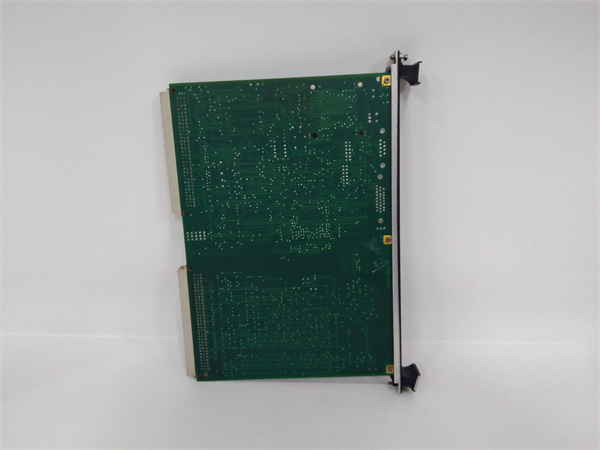

1. Product Description

The IS200VTCCH1CBB serves as a critical interface for temperature measurement in GE’s Mark VI turbine control systems. It accepts 24 thermocouple inputs (grounded/ungrounded) with linearization support via Mark VI software, ensuring accurate temperature data for turbine efficiency and safety. The board features dual cold-junction compensation, high-frequency noise suppression, and a compact design (2.1 × 18.8 × 26.2 cm) with DIN-rail mounting. Key components include an Xilinx Spartan XCS30 FPGA, dual-port SRAM, and DSP for real-time signal processing. Compatible with TBTCH1C (simplex) or TBTCH1B (triple modular redundant, TMR) terminal boards, it supports simplex/TMR configurations for redundant control systems.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Brand | GE Fanuc |

| Series | Mark VI (Speedtronic Turbine Control) |

| Type | Thermocouple Input Terminal Board |

| Input Signals | 24 thermocouples (E/J/K/S/T) or mV (-8 to +45 mV) |

| Compatibility | GE Mark VI systems, TBTCH1C/TBTCH1B boards |

| Dimensions | 2.1 cm (W) × 18.8 cm (H) × 26.2 cm (D) |

| Weight | 0.3 kg (0.66 lbs) |

| Power Supply | 24VDC (via Mark VI chassis) |

| Signal Isolation | Galvanic isolation (grouped per terminal block) |

| Cable Length | Up to 300 m (984 ft) |

| Temperature Range | -40°C to +85°C (operating); -55°C to +125°C (storage) |

| Mounting | DIN rail (Mark VI chassis integration) |

| Protection | Conformal coating (IP20), overvoltage/current protection |

IS200VTCCH1CBB

3. Advantages and Features

- High Precision: Cold-junction compensation and linearization ensure ±0.1% temperature accuracy.

- Redundancy Support: TMR capability via TBTCH1B board for fault-tolerant systems (e.g., offshore turbines).

- Harsh Environment Resilience: Conformal coating resists moisture, dust, and vibration (IEC 60068-2-6 vibration test compliance).

- Scalability: Supports up to 24 thermocouples with 450 Ω max cable resistance for distributed sensor networks.

- Diagnostics: Automatic input validation; signals outside hardware limits are quarantined (GEH-6421 manual compliance).

4. Application Areas and Use Cases

- Industry: Power generation (gas/steam turbines), oil & gas (refineries), manufacturing (rotating machinery).

- Case Study: A U.S. power plant used IS200VTCCH1CBB in a TMR configuration for a 700MW steam turbine. The board’s 24-channel temperature monitoring detected a 120°C hot spot in a bearing during startup, triggering a proactive shutdown. This prevented $1.5M in repair costs and 48 hours of downtime.

5. Competitive Comparison

Compared to standard thermocouple input modules:

- Channel Density: 24 inputs (vs. 12–16 in most alternatives).

- Redundancy Flexibility: Native TMR support (no external adapters).

- Signal Range: Wider mV span (-8 mV to +45 mV vs. typical 0–20 mV).

- Environmental Rating: Conformal coating standard (vs. optional in 竞品).

IS200VTCCH1CBB

6. Selection Recommendations

- System Type: Use with GE Mark VI systems (Frame 5/6/7 turbines) requiring temperature monitoring.

- Redundancy: Pair with TBTCH1B for TMR systems (critical applications like nuclear backup power).

- Environment: Select conformal coating for coastal/moist environments; derate for >50°C ambient.

- Expansion: Combine with IS215VCMIH1B (communication module) for full Mark VI integration.

7. Precautions

- Installation:

- Follow ESD protocols (anti-static gloves, grounded workspace).

- Torque terminal screws to 0.5–0.7 N·m; avoid loose connections.

- Maintenance:

- Inspect capacitors for swelling every 3 years (expected lifespan: 10 years).

- Verify cold-junction accuracy annually (±0.5°C tolerance).

- Safety:

- Disconnect power before servicing (24VDC isolation required).

- Avoid exposure to conductive dust; IP20-rated (indoor use only).