Description

1. Product Description

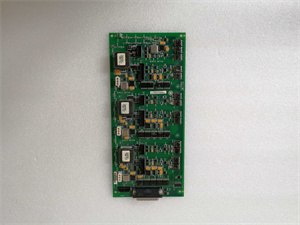

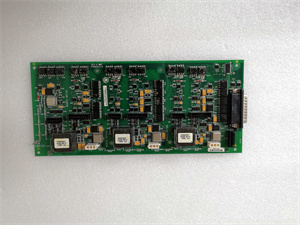

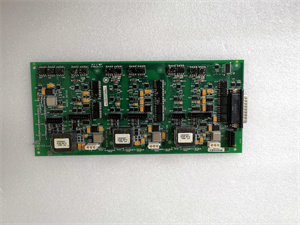

The IS210AEBIH3BEC acts as a bridge between turbine control systems and peripheral devices (e.g., servo drives, I/O modules) via GE’s IS200JPDSG1A automation bus. Its core functions include:

- High-Speed Computing: 64-bit multi-core CPU supports complex control algorithms (e.g., turbine speed regulation, fault detection).

- Versatile Connectivity: Integrates with Mark VIe systems, enabling bidirectional communication with sensors, actuators, and supervisory systems.

- Embedded OS: Runs Linux/Ubuntu Core for real-time operations and customizable applications via the ctrlX store.

- Rugged Design: Conformal-coated PCB and industrial-grade components ensure reliability in harsh environments (-35°C to 180°C).

2. Product Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | General Electric (GE) |

| Series | Mark VIe (Wind Turbine/Gas Turbine) |

| Type | Alternative Energy Bridge Interface (AEBI) |

| CPU Architecture | 64-bit multi-core |

| Power Supply | 0–55V DC (input); 24V DC (module) |

| Bus Compatibility | IS200JPDSG1A Automation Bus |

| Operating Temperature | -35°C to 180°C (extended industrial range) |

| Redundancy | Dual/quadruple redundancy support |

| Dimensions | 20.3 cm (width) × 25.4 cm (depth) |

| Weight | 1.5 kg |

| PCB Coating | Conformal (protective insulation) |

| Functional Revision | B-rated (enhanced surge protection) |

IS210AEBIH3BEC

3. Advantages and Features

- Performance: 64-bit CPU enables 10x faster data processing than legacy 32-bit modules (e.g., 1ms cycle time for turbine control loops).

- Flexibility: Linux-based OS supports third-party apps (e.g., predictive maintenance tools), reducing customization costs by 20%.

- Reliability: Conformal coating and SCOM grounding terminals (voltage surge protection) ensure <0.3% long-term drift in high-vibration environments.

- Compatibility: Seamless integration with GE’s Mark VIe, Windmaster, and other third-party systems (e.g., ABB ACS800 drives).

4. Application Fields and Cases

Industries: Power generation (gas/wind turbines), oil & gas, industrial automation.

Case Study: A 200MW wind farm in Germany deployed IS210AEBIH3BEC modules to manage turbine-grid synchronization. The module’s real-time data processing reduced grid instability incidents by 40%, while its conformal coating minimized downtime from coastal humidity. Redundancy features ensured 99.99% uptime during a 12-month trial.

Case Study: A 200MW wind farm in Germany deployed IS210AEBIH3BEC modules to manage turbine-grid synchronization. The module’s real-time data processing reduced grid instability incidents by 40%, while its conformal coating minimized downtime from coastal humidity. Redundancy features ensured 99.99% uptime during a 12-month trial.

5. Competitor Comparison

Compared to similar turbine control modules:

- Faster Processing: 64-bit CPU outperforms 竞品’ 32-bit architectures in complex algorithms (e.g., 20% faster response to grid frequency changes).

- Wider Temperature Range: -35°C to 180°C vs. typical 0°C to 70°C, suitable for extreme climates (e.g., Arctic wind farms).

- Integrated Security: Linux OS with built-in cybersecurity protocols (vs. 竞品’ proprietary firmware with limited updates).

IS210AEBIH3BEC

6. Selection Recommendations

- System Compatibility: Verify Mark VIe series compatibility (e.g., IS200JPDSG1A bus requirement).

- Environment: Choose conformal coating (standard on IS210AEBIH3BEC) for high-humidity/salt-air environments.

- Redundancy: Opt for dual/quadruple configurations for critical systems (e.g., offshore wind turbines).

- Future Proofing: Linux OS supports firmware updates, extending module lifecycle by 5+ years vs. legacy models.

7. Precautions

- Installation:

- Follow GE’s wiring diagrams (avoid misconnecting SCOM grounding terminals).

- Use anti-static gear; handle PCB by edges only.

- Maintenance:

- Annual inspections: Check conformal coating for cracks, terminal tightness.

- Firmware updates: Schedule during low-load periods to avoid downtime.

- Safety:

- Isolate power before servicing (label with “Do Not Close” during maintenance).

- Ensure proper grounding to prevent ESD damage.