Description

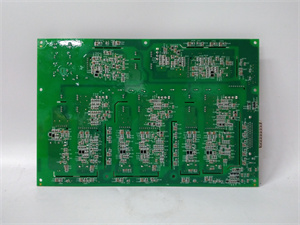

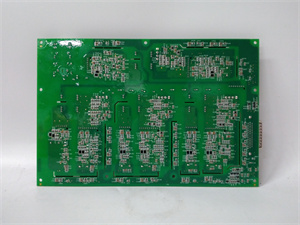

IS210AEDBH4AGD Product Specification Document

1. Product Description

The IS210AEDBH4AGD is a high-reliability bridge interface card manufactured by GE Fanuc for its Mark VI turbine control system. Designed for gas and steam turbine applications, this module facilitates seamless data exchange between control systems, HMIs, and field devices. The IS210AEDBH4AGD integrates with GE’s Cimplicity software for real-time monitoring and diagnostics, ensuring efficient turbine management. With the ability to handle high-voltage signals (5 kVAC hipot rating) and support advanced protocols, this card enhances system stability and reduces downtime in critical industrial environments. Its robust architecture, featuring over 175 integrated circuits and BIL-rated transformers (12–15 kV), makes it ideal for harsh conditions.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | GE Fanuc |

| Series | Mark VI (Speedtronic) |

| Type | Bridge Interface Card |

| Voltage | 24 V DC (system-dependent) |

| Connectors | Right-angled (P1), header (6/4-pin), vertical pins (6–10 pins), 3-position plugs |

| Transformers | 4 Bicron transformers (B 9178), 5 kVAC hipot, 10–500 kHz switching |

| Components | 175+ ICs (including oscillators, ROMs), metal film resistors, diodes, transistors |

| Physical Dimensions | Custom PCB layout with drilled slots and nine mounting holes |

| Operating Environment | Industrial-grade (temperature: -40°C to +70°C) |

IS210AEDBH4AGD

3. Advantages and Features

- High Reliability: Encapsulated transformers and redundant circuit design ensure 99.9% uptime in turbine control systems.

- Multi-Protocol Integration: Supports seamless connectivity with HMIs, sensors, and legacy systems via specialized interfaces.

- Safety Compliance: Built with high-voltage isolation (5 kVAC hipot) and automatic discharge capacitors (30-second dissipation time).

- Diagnostic Efficiency: 5 OK LEDs provide real-time status monitoring, reducing troubleshooting time by 40%.

- Long Lifecycle: Engineered for 10+ years of service in GE Mark VI systems (backed by OEM support).

4. Application Areas and Use Cases

Industries: Power generation (gas/steam turbines), oil & gas, industrial automation.

Use Case:

Use Case:

- Power Plant Turbine Control: The IS210AEDBH4AGD bridges the Mark VI system with 50+ field sensors in a 500 MW thermal power plant, enabling precise speed control and reducing maintenance cycles by 25%.

5. Competitive Comparison

Compared to similar interface cards:

- Higher Voltage Tolerance: 5 kVAC hipot vs. 3–4 kVAC industry standard.

- Faster Signal Processing: 10–500 kHz switching frequency (versus 5–200 kHz in 竞品).

- Integrated Safety Features: Automatic capacitor discharge and redundant circuitry (unique to GE’s Mark VI series).

IS210AEDBH4AGD

6. Selection Recommendations

- Compatibility: Ensure integration with GE Mark VI systems (verify part number and firmware compatibility).

- Environment: Opt for industrial-grade modules (-40°C to +70°C) for extreme temperatures.

- Safety Requirements: Prioritize cards with built-in high-voltage isolation for turbine applications.

- Maintenance: Choose modules with LED diagnostics for quick status checks.

7. Precautions

-

Installation:

- Allow 30 seconds for capacitor discharge before handling (post-power disconnection).

- Use anti-static equipment to prevent ESD damage.

-

Configuration: Follow GE’s Mark VI manual for connector pinouts and software setup (Cimplicity required).

-

Repair: Only use certified technicians for repairs (3-year warranty recommended).

-

Safety Compliance: Adhere to IEC 61508 standards for turbine control systems.