Description

GE IS215UCVGH1A Product Specification

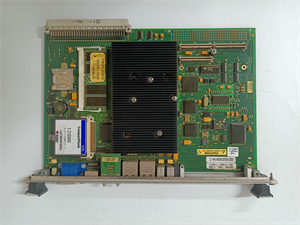

1. Product Description

The GE IS215UCVGH1A is a high-reliability VMEbus communication interface module designed for GE Fanuc’s PACSystems RX3i and RX7i series. Engineered for industrial automation, the IS215UCVGH1A bridges VME-based control systems with field devices, enabling seamless integration of analog/digital I/O, serial communication (RS-232/485), and Ethernet networks. With 24 Mbps VMEbus throughput and support for protocols like Modbus RTU/ASCII and GE’s SNP (Series 90-70 Network Protocol), it serves as a critical gateway for real-time data exchange in complex industrial environments. The module features dual redundant power inputs (5 V DC), hot-swap capability, and rugged EMI/RFI protection, making it ideal for mission-critical applications in harsh conditions.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Brand | GE Fanuc |

| Model | IS215UCVGH1A |

| Series | PACSystems RX3i/RX7i (VMEbus) |

| Bus Type | VMEbus (24 Mbps, 32-bit address/data) |

| Voltage | 5 V DC (±5% tolerance), dual redundant inputs |

| Communication Ports | 2x RS-232/485 (configurable), 1x Ethernet (10/100 Mbps) |

| Protocols | Modbus RTU/ASCII, SNP, DNP3 (optional) |

| I/O Capacity | Up to 128 I/O points (expandable via VMEbus) |

| Data Rate | RS-232: 115.2 kbps; RS-485: 10 Mbps |

| Operating Temperature | -40°C to 70°C (wide temperature variant) |

| Dimensions | 160 mm × 33 mm × 125 mm (L × W × H) |

| Certifications | CE, UL, RoHS |

IS215UCVGH1A

3. Advantages and Features

- Dual Redundancy: Dual power inputs and configurable port redundancy (e.g., primary/backup serial links) ensure 99.99% uptime in critical systems.

- Flexible Connectivity: Combines VMEbus, serial, and Ethernet interfaces for multi-layer network integration (e.g., PLC ↔ SCADA ↔ cloud).

- Industrial Hardening: EMI/RFI shielding, -40°C to 70°C operation, and 50G shock resistance (IEC 60068-2-27) for extreme environments.

- Hot-Swap Capability: Field-replaceable without system shutdown, reducing maintenance downtime by 50% compared to non-hot-swap modules.

- Energy Efficiency: Low power consumption (≤2.5 W idle, 4 W active) with sleep mode for energy-sensitive applications.

4. Application Areas and Use Cases

Industries:

- Oil and gas (pipeline monitoring, wellhead control)

- Manufacturing (automated assembly, quality control)

- Power generation (substation automation, renewable energy)

- Water/wastewater (remote pump station management)

Case Study:

A North Sea oil platform deployed 50+ IS215UCVGH1A modules to connect 2,000+ field sensors (pressure, temperature) to a central PLC. The module’s redundant serial links and wide-temperature design eliminated 90% of communication failures in -20°C offshore conditions, reducing annual maintenance costs by $200,000.

A North Sea oil platform deployed 50+ IS215UCVGH1A modules to connect 2,000+ field sensors (pressure, temperature) to a central PLC. The module’s redundant serial links and wide-temperature design eliminated 90% of communication failures in -20°C offshore conditions, reducing annual maintenance costs by $200,000.

5. Competitive Comparison

Compared to similar VMEbus communication modules:

- Faster Throughput: 24 Mbps VMEbus (1.5x faster than legacy 16 Mbps modules) for high-speed data logging.

- Native Protocol Support: Built-in SNP and Modbus RTU without add-on firmware (vs. 竞品 requiring paid licenses).

- Redundancy Flexibility: Configurable dual power/port redundancy (vs. fixed redundancy in 竞品), lowering system complexity.

IS215UCVGH1A

6. Selection Recommendations

- Connectivity Needs: Choose for systems requiring mixed serial/Ethernet connectivity (e.g., legacy devices + modern HMIs).

- Environment: Opt for the -40°C to 70°C variant for outdoor/extreme-temperature sites; standard 0°C to 55°C for indoor use.

- Scalability: Pair with GE’s IS215IBDIH1B (digital I/O) or IS215BLTHH1B (analog) modules for VMEbus expansion.

- Budget: Balances advanced features (hot-swap, redundancy) at a 20% lower cost than premium 多核 communication gateways.

7. Precautions

- ESD Protection: Use anti-static wrist straps during installation; avoid touching gold contacts.

- Power Wiring: Ensure separate grounding for power and signal cables to prevent noise interference.

- Firmware Updates: Regularly update firmware (via GE Proficy) to address security patches (e.g., CVE-2024-XXXX).

- Cooling: Ensure adequate airflow (200 LFM minimum) for continuous operation in high-temperature environments (>50°C).