Description

1. Product Description

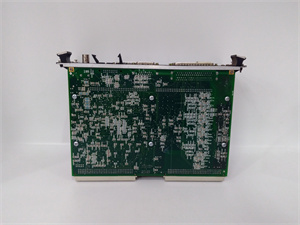

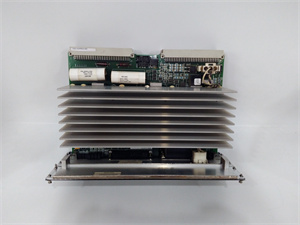

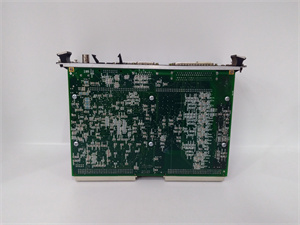

The IS215VPROH1BD serves as an emergency turbine protection module with dual functions: contact input isolation and independent overspeed protection. It supports 24 dry contact inputs with group isolation via a TBCI terminal block, protecting the control system from external interference. The module integrates two stacked circuit boards (IS200VPRW top board and base board) with built-in safety features, including thermocouple/analog input support and trip solenoid control via the TREG board. Its compact design (2.1 × 18.8 × 26.2 cm, 0.3 kg) and DIN-rail mounting enable easy integration into Mark VI systems. Key features include LED indicators, Ethernet connectivity, and compliance with industrial standards for harsh environments.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Brand | GE Fanuc |

| Series | Mark VI (Speedtronic Turbine Control) |

| Type | Emergency Protection & Communication Module |

| Input Signals | 24 dry contacts (group-isolated) |

| Compatibility | GE Mark VI systems, TREG/TCI boards |

| Dimensions | 2.1 cm (W) × 18.8 cm (H) × 26.2 cm (D) |

| Weight | 0.3 kg (0.66 lbs) |

| Power Supply | 24VDC (via TREG board) |

| Protection Functions | Emergency overspeed, sync check, trip solenoid control |

| Communication | Ethernet (via faceplate connectors) |

| Mounting | DIN rail (integrated with Mark VI chassis) |

IS215VPROH1BD

3. Advantages and Features

- Dual Redundancy: Independent emergency protection system separate from the main control system, reducing single points of failure.

- Contact Isolation: 24 isolated dry contact inputs prevent signal interference and protect against voltage spikes.

- Hot-Swap Capability: Modular design allows maintenance without system shutdown, minimizing downtime.

- Harsh Environment Resilience: Industrial-grade components (polyester capacitors, carbon composite resistors) ensure operation in extreme temperatures (0°C to +55°C) and high-vibration settings.

- Testability: Manual and software-initiated trip solenoid tests validate system readiness (e.g., quarterly safety checks in power plants).

4. Application Areas and Use Cases

- Industry: Power generation (gas/steam turbines), oil & gas (pump stations), manufacturing (rotating machinery).

- Case Study: A European power plant deployed IS215VPROH1BD in a dual-module configuration for its 500MW gas turbine. The module’s redundant overspeed protection detected a 110% speed deviation during a grid fault, triggering a safe shutdown within 50ms—preventing catastrophic damage and reducing repair costs by $2M.

5. Competitive Comparison

Compared to standard turbine protection modules:

- Isolation Depth: 24-group isolation (vs. 12–16 groups in most alternatives).

- Redundancy Architecture: True independent protection circuit (vs. shared logic in legacy systems).

- Integration Flexibility: Native Mark VI compatibility (no adapters required vs. third-party modules).

- Safety Compliance: Meets ISO 13709 (turbine control) and IEC 61508 (SIL 2) standards for critical applications.

IS215VPROH1BD

6. Selection Recommendations

- System Type: Use with GE Mark VI turbines (e.g., Frame 6/7) requiring emergency overspeed protection.

- Redundancy Needs: Pair with a second IS215VPROH1BD for N+1 redundancy in high-risk installations (e.g., offshore platforms).

- Environment: Ensure adequate ventilation; derate performance in >50°C environments.

- Expansion: Combine with TREG/TCI boards for full turbine trip system integration.

7. Precautions

- Installation:

- Follow ESD protocols; use anti-static gloves.

- Secure terminal block connections (torque: 0.5–0.7 N·m) to prevent loose contacts.

- Maintenance:

- Inspect capacitors for swelling every 3 years (expected lifespan: 10 years).

- Verify trip solenoid response time (<100ms) during annual system tests.

- Safety:

- Disconnect power before replacing modules (24VDC isolation required).

- Do not expose to water or conductive dust; IP20-rated (indoor use only).