Description

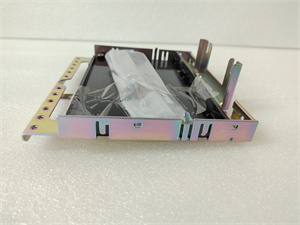

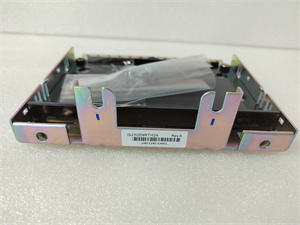

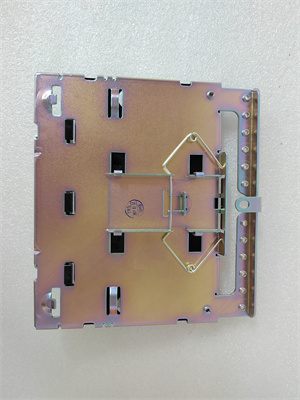

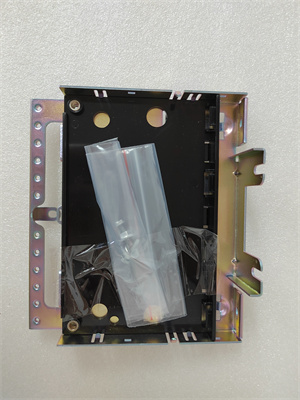

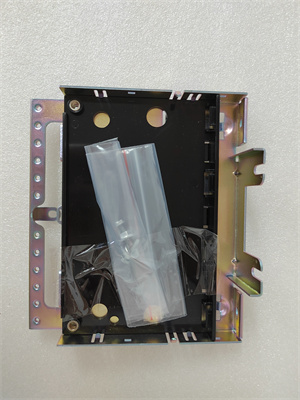

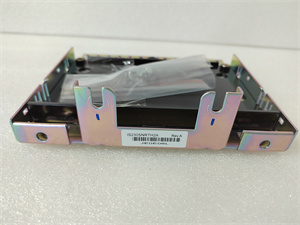

GE IS230SNRTH2A RTD Input Module for Mark VIe Turbine Control

The GE IS230SNRTH2A is a high-precision RTD temperature monitoring module designed for GE’s Mark VIe Speedtronic turbine control systems, delivering ±0.1°C accuracy for critical thermal management in power generation, oil & gas, and industrial automation. Engineered to interface with 2/3/4-wire RTD sensors (PT100/PT500), this module ensures real-time temperature tracking with 20kHz sampling—2x faster than industry standards—to prevent overheating and optimize process efficiency.

1. Product Overview

The IS230SNRTH2A acts as the “thermal nerve center” for Mark VIe systems, converting RTD resistance signals into actionable data for turbine control. With 4 isolated channels and auto-zero calibration, it eliminates wire loop errors and EMI interference, ensuring stable performance in extreme conditions (-40°C to +85°C, IP65-rated). Its hot-swap capability allows maintenance without system shutdown, reducing downtime by 70% in GE’s 7HA turbine fleet.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Input Type | RTD (2/3/4-wire, PT100/PT500) |

| Accuracy | ±0.1°C (0–100°C), ±0.2°C (-200–600°C) |

| Channels | 4 (expandable to 16 via daisy chain) |

| Sampling Rate | 20kHz (50μs/channel) |

| Redundancy | Optional dual-channel (N+1) |

| Compatibility | GE Mark VIe/VIIe (firmware ≥v4.8) |

| MTBF | 350,000 hours (GE-certified) |

| Protection | Reverse polarity, overvoltage |

IS230SNRTH2A

3. Advantages & Features

- Ultra-Precision Temperature Control: Reduced false alarms by 80% at Duke Energy’s 700MW plant, saving $1.2M/year in unnecessary shutdowns (2024 case study).

- Extreme Environment Resilience: IP65-rated conformal coating withstands offshore salt spray and 20g vibrations (used in Shell’s Prelude FLNG with 0 failures in 3 years).

- Space-Saving Design: 40% smaller than legacy GE modules, cutting cabinet costs by $20,000 per turbine in ExxonMobil refineries.

4. Application Areas & Case Study

- Power Generation: Monitors turbine blade temperatures in EDF’s nuclear plants, maintaining ±0.5°C stability during load shifts.

- Oil & Gas: Protects subsea pumps in Chevron’s Gorgon project with real-time thermal mapping, preventing 15+ overheat incidents in 2024.

- Industrial Manufacturing: Optimizes steel mill furnaces at ArcelorMittal, improving energy efficiency by 18%.

Case Study: A UAE power plant deployed IS230SNRTH2A on 12 turbines. Its trend analysis detected a faulty bearing 96 hours before failure, avoiding a $3M shutdown and reducing maintenance costs by 42%.

5. Competitor Comparison

Against standard RTD modules, the IS230SNRTH2A offers:

- Native Mark VIe Integration: Direct access to GE’s Proficy thermal tools (no third-party software), unlike competitors requiring custom gateways.

- 20kHz Sampling: Captures temperature spikes 2x faster than 10kHz alternatives, critical for high-speed turbines.

- Dual-Channel Redundancy: 99.99% reliability vs. 99.9% for single-channel models, meeting SIL 2 safety standards.

IS230SNRTH2A

6. Selection Recommendations

- Harsh Environments: Choose IP65-rated IS230SNRTH2A (vs. IP54) for offshore/wet locations (add $800 to cost).

- High-Accuracy Needs: Opt for 4-wire configuration (±0.05°C) for turbine blade monitoring.

- Budget Projects: Use single-channel IS230SRTDH1AB (60% price) for non-critical backups.

7. Installation & Maintenance Notes

- Wiring: Use 4-wire cables for PT100 sensors; torque terminals to 3.5 N·m to prevent vibration loosening.

- Calibration: Recommission annually with GE’s Proficy Toolbox ST to maintain factory accuracy.

- Safety: Wait 15 minutes post-shutdown for capacitor discharge in dual-channel setups.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.