Description

1. Product Description

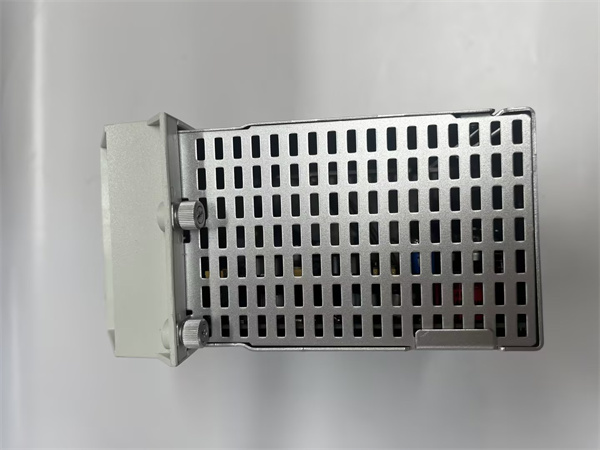

The REXROTH PPC-R22.1N-N-Q1-NN-NN-FW is a high-performance multi-axis motion and logic controller designed for industrial automation applications requiring precise control and flexibility. As part of Bosch Rexroth’s PPC (Programmable Position Controller) series, this module combines advanced digital signal processing (DSP) technology with a modular architecture to deliver reliable performance in complex manufacturing environments. The PPC-R22.1N-N-Q1-NN-NN-FW supports both PLC and NC (Numerical Control) functionalities, making it suitable for applications ranging from robotic assembly to CNC machining.

Key features include:

- Dual Control Modes: Operates as a PLC for general automation tasks or as an NC controller for high-precision motion control, enabling seamless integration into diverse production lines.

- Multi-Protocol Connectivity: Equipped with ArcNet and Profibus-DP interfaces for communication with drives, HMIs, and other networked devices, ensuring compatibility with legacy and modern industrial systems.

- Real-Time Monitoring: Supports closed-loop control with feedback from inductive position sensors and pressure transducers, maintaining accuracy within ±0.5% for critical processes like engine block assembly.

- Compact Design: Housed in an IP20-rated enclosure, the controller fits into standard REXROTH RECO 02 racks, optimizing space in control cabinets.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | PPC-R22.1N-N-Q1-NN-NN-FW |

| Brand | REXROTH |

| Type | Multi-Axis Motion and Logic Controller |

| Input Voltage | 24V DC ±10% (19.2–30V DC with ripple) |

| Output Current | 2.0A continuous, 4.0A peak (30s) |

| Control Modes | Position control, velocity control, torque control |

| Communication Interfaces | ArcNet, Profibus-DP, RS232/485/422, SERCOS fiber optic |

| Encoder Resolution | 12-bit (4,096 pulses/revolution) |

| Protection Class | IP20 (suitable for control cabinets) |

| Dimensions (WxHxD) | 83.7 mm x 192 mm x 150 mm |

| Weight | 1.3 kg |

| Compatibility | REXROTH RECO 02 racks, ECodrive 03/Diax04 drives |

| Firmware | VisualMotion or GPP 10 (optional) |

PPC-R22.1N-N-Q1-NN-NN-FW

3. Advantages and Features

-

Precision Control:

The PPC-R22.1N-N-Q1-NN-NN-FW achieves ±0.5% torque accuracy and ±0.01 mm position repeatability, ensuring consistent performance in high-precision applications like aerospace component assembly. Its closed-loop control compensates for friction and material variations, reducing defects by up to 30% compared to open-loop systems. -

Flexible Programming:

Supports 16 pre-programmed parameter sets for quick changeovers between tasks, such as switching from automotive engine assembly to consumer electronics manufacturing. Users can define custom sequences via VisualMotion Toolkit software, enhancing productivity in high-mix production lines. -

Energy Efficiency:

With 98% operational efficiency under nominal load, the controller minimizes power consumption. Regenerative braking technology recovers energy during deceleration, lowering long-term operational costs. -

Scalability:

Controls up to 8 axes simultaneously via SERCOS fiber optic interfaces, ideal for multi-station assembly lines. Its modular design allows expansion with additional I/O modules for complex automation setups. -

Safety Compliance:

Compliant with EN 61800-5-2 (SIL3/PLe) safety standards, the controller includes features like safe torque-off (STO) and emergency stop functionality, ensuring operator and machine safety.

4. Application Areas and Case Studies

Industry Applications

- Automotive Manufacturing: Used in engine block assembly, transmission installation, and chassis welding to ensure precise fastener tightening.

- Aerospace: Supports aircraft wing assembly and turbine component fastening, meeting strict safety regulations.

- Robotics: Enables high-speed pick-and-place operations and collaborative robot (cobot) control in electronics manufacturing.

- CNC Machining: Provides NC functionality for milling, turning, and grinding machines, delivering sub-micron precision.

Case Study

A leading automotive supplier integrated the PPC-R22.1N-N-Q1-NN-NN-FW into their cylinder head assembly line to address inconsistent torque values causing leaks. The controller’s real-time monitoring and closed-loop control reduced tightening errors by 35%, improving first-pass yield from 85% to 98%. The multi-axis capability also increased line throughput by 20% by simultaneously controlling eight tightening spindles.

5. Competitor Comparison

| Feature | REXROTH PPC-R22.1N-N-Q1-NN-NN-FW | Competitor A | Competitor B |

|---|---|---|---|

| Torque Accuracy | ±0.5% | ±1.0% | ±0.8% |

| Axis Control | 8 axes | 4 axes | 6 axes |

| Communication Protocols | ArcNet, Profibus-DP, SERCOS | Profibus-DP only | Ethernet/IP |

| Safety Compliance | SIL3/PLe | SIL2 | SIL3 |

| Energy Efficiency | 98% | 95% | 96% |

The PPC-R22.1N-N-Q1-NN-NN-FW outperforms competitors in torque accuracy, axis scalability, and multi-protocol support, making it ideal for complex, high-precision applications.

PPC-R22.1N-N-Q1-NN-NN-FW

6. Selection Recommendations

When selecting the PPC-R22.1N-N-Q1-NN-NN-FW, consider the following:

- Control Requirements: Ensure its 8-axis capability and ±0.5% torque accuracy align with your application’s precision needs.

- Communication Needs: Verify compatibility with your plant’s network infrastructure (e.g., ArcNet, Profibus-DP).

- Safety Standards: The SIL3/PLe rating is critical for safety-critical environments like automotive assembly.

- Space Constraints: The compact 83.7 mm x 192 mm x 150 mm design fits into tight control cabinets.

- Scalability: For multi-station lines, the ability to control up to 8 axes reduces hardware complexity compared to single-axis solutions.

7. Precautions

-

Installation:

- Mount vertically in a REXROTH RECO 02 rack using M4 screws to ensure stable operation and heat dissipation.

- Use shielded cables for encoder and power connections to minimize electromagnetic interference (EMI).

-

Electrical Safety:

- Disconnect power before installation or maintenance.

- Ensure input voltage remains within 24V DC ±10% to avoid damage.

-

Calibration:

- Regularly calibrate using VisualMotion Toolkit software to maintain accuracy, especially after environmental changes.

-

Maintenance:

- Inspect connectors for loose connections and clean dust from vents quarterly.

- Replace worn components immediately to prevent system downtime.

-

Firmware Updates:

- Keep the controller’s firmware up-to-date via official channels to access new features and security patches.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.